Preparation technology for steel-surface in-situ ceramic layer used in low-temperature aluminizing petroleum pipeline

A technology for pipeline steel and preparation process, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problem of preparing anti-corrosion ceramic layer, etc. High bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

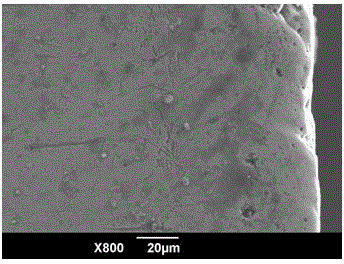

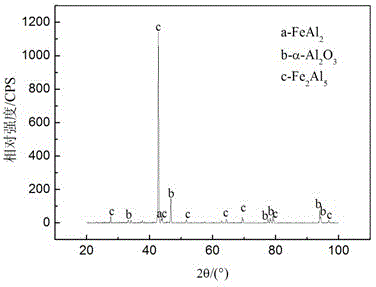

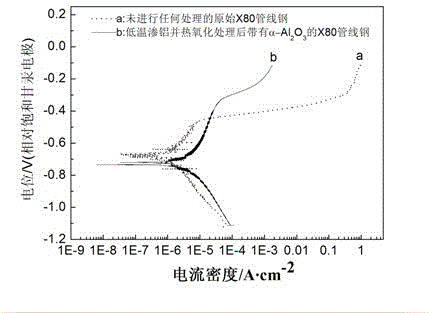

Image

Examples

Embodiment 1

[0027] A process for preparing an in-situ ceramic layer on the surface of steel for low-temperature aluminized oil pipelines, comprising the following steps:

[0028] (1) Low temperature aluminizing

[0029] Mix 300-mesh aluminum powder, 300-mesh zinc powder, and ammonium chloride powder evenly according to the following mass ratio to make 100 g of embedding agent:

[0030] Aluminum powder 60%

[0031] Zinc powder 38.5%

[0032] Ammonium Chloride Powder 1.5%.

[0033] The petroleum pipeline steel after the surface mechanical grinding treatment was embedded in the above embedding infiltration agent, and the embedding aluminizing treatment was carried out. The embedding aluminizing temperature was 470° C., and the embedding treatment was performed for 2 hours.

[0034] (2) Thermal oxidation treatment

[0035] Put the oil pipeline steel after step 1 low-temperature aluminized into a tubular atmosphere resistance furnace heated to a certain temperature, feed oxygen and keep wa...

Embodiment 2

[0039] A process for preparing an in-situ ceramic layer on the surface of steel for low-temperature aluminized oil pipelines, comprising the following steps:

[0040] (1) Low temperature aluminizing

[0041] Mix 300-mesh aluminum powder, 300-mesh zinc powder, and ammonium chloride powder evenly according to the following mass ratio to make 100 g of embedding agent:

[0042] Aluminum powder 80%

[0043] Zinc powder 18.5%

[0044] Ammonium Chloride Powder 1.5%.

[0045] The oil pipeline steel after the surface mechanical grinding treatment was embedded in the above embedding infiltration agent, and the embedding aluminizing treatment was carried out. The embedding aluminizing temperature was 530° C., and the embedding treatment was performed for 1 hour.

[0046] (2) Thermal oxidation treatment

[0047] Put the oil pipeline steel after step 1 low-temperature aluminized into a tubular atmosphere resistance furnace heated to a certain temperature, feed oxygen and keep warm to f...

Embodiment 3

[0051] A process for preparing an in-situ ceramic layer on the surface of steel for low-temperature aluminized oil pipelines, comprising the following steps:

[0052] (1) Low temperature aluminizing

[0053] Mix 300-mesh aluminum powder, 300-mesh zinc powder, and ammonium chloride powder evenly according to the following mass ratio to make 100 g of embedding agent:

[0054] Aluminum powder 70%

[0055] Zinc powder 28.5%

[0056] Ammonium Chloride Powder 1.5%.

[0057] Embed the oil pipeline steel after the surface mechanical grinding treatment in the above-mentioned embedding infiltration agent, and perform embedding aluminizing treatment. The embedding aluminizing temperature is 500 ° C, and the embedding treatment is performed for 3 hours;

[0058] (2) Thermal oxidation treatment

[0059] Put the oil pipeline steel after step 1 low-temperature aluminizing into a tubular atmosphere resistance furnace heated to a certain temperature, feed oxygen and keep warm to form a cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com