Method for preparing fine-grain high-density TZM (Titanium-Zirconium-Molybdenum Allo) alloy

A dense and alloy technology, applied in the field of preparing fine-grained high-density TZM alloys, can solve the problems affecting the mechanical properties of TZM alloys, low alloy density, large porosity, etc., to solve the problems of difficult control of uniformity, uniform distribution, and improved effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

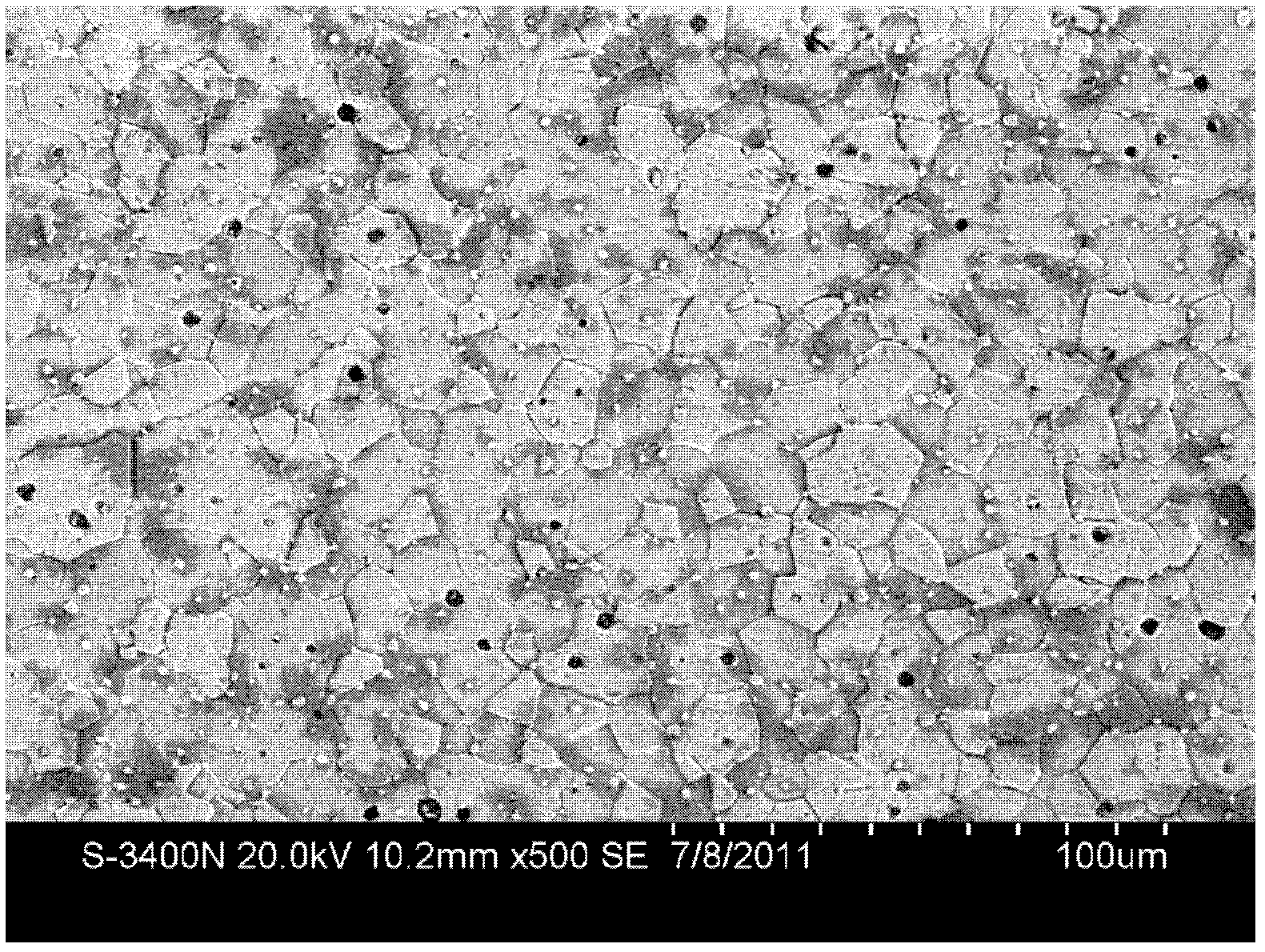

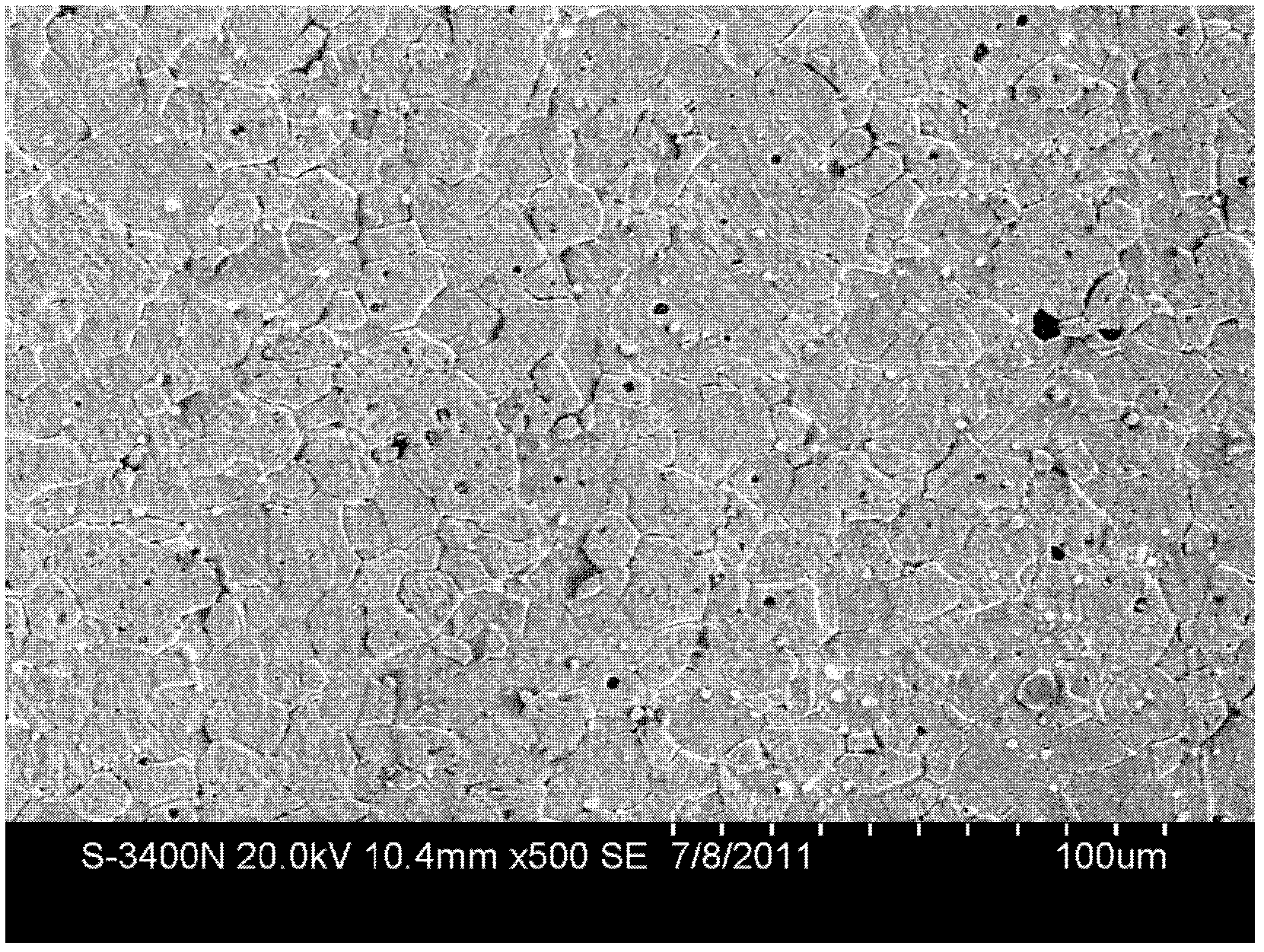

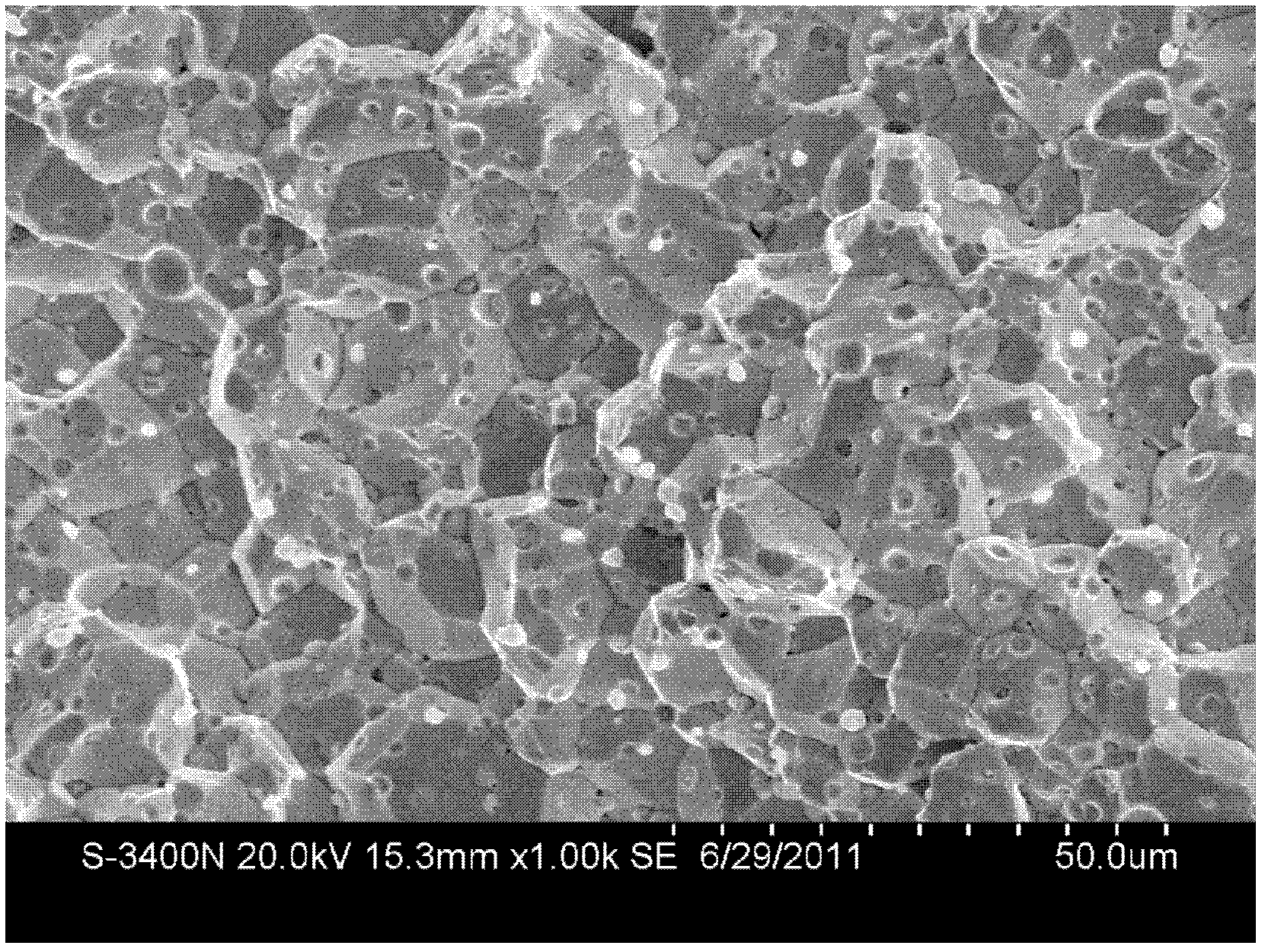

Image

Examples

Embodiment 1

[0033] Raw materials: molybdenum powder particle size 2μm, TiH 2 Powder and ZrH 2 The particle size of the powder is 5 μm, the particle size of the graphite powder is 10 μm, La 2 o 3 The particle size of the powder is 0.5 μm.

[0034] Prepare alloy powder according to the following mass percentage: TiH 2 : 0.45%, ZrH 2 : 0.06%, graphite powder: 0.05%, La 2 o 3 Powder is 0.5%, and molybdenum powder makes up 100%;

[0035] Put the alloy powder into a three-dimensional blender according to the formula and mix for 2 hours, the speed of the blender is 30r / min, to obtain evenly mixed alloy powder.

[0036] Put the mixed alloy powder into a ball mill for ball milling. The ball mill speed is 50r / min. Molybdenum balls with a diameter of 10mm are placed in the ball mill. The mass ratio of molybdenum balls to alloy powder is 2:1, and the ball milling time is 2 hours.

[0037] The alloy powder after ball milling is formed by compression molding, the pressure is 50Mpa, and the hold...

Embodiment 2

[0041] Raw materials: molybdenum powder with particle size of 3.5μm, TiH 2 and ZrH 2 The particle size of the powder is 8 μm, the particle size of the graphite powder is 6 μm, La 2 o 3 The powder particle size is 0.5 μm.

[0042] Prepare alloy powder according to the following mass percentage: TiH 2 : 0.65%, ZrH 2 : 0.14%, graphite powder: 0.06%, La 2 o 3 Powder: 1.5%, molybdenum powder makes up 100%;

[0043] Put the prepared alloy powder into a three-dimensional blender and mix for 4 hours, the speed of the blender is 60r / min, to obtain a uniformly mixed alloy powder.

[0044]Put the mixed alloy powder into a ball mill for ball milling. The ball mill speed is 200r / min. Molybdenum balls with a diameter of 10mm are placed in the ball mill. The mass ratio of molybdenum balls to alloy powder is 2:1, and the ball milling time is 24 hours.

[0045] The alloy powder after ball milling was formed by isostatic pressing with a pressure of 200Mpa and a holding time of 60s.

[...

Embodiment 3

[0049] Raw materials: molybdenum powder particle size 3μm, TiH 2 and ZrH 2 The particle size of the powder is 7μm, the graphite powder particle size is 8μm, La 2 o 3 The powder particle size is 1 μm.

[0050] Prepare alloy powder according to the following mass percentage: TiH 2 : 0.5%, ZrH 2 : 0.09%, graphite powder: 0.05%, La 2 o 3 Powder: 1%, molybdenum powder makes up 100%.

[0051] Put the prepared alloy powder into a three-dimensional blender and mix for 3 hours, and the speed of the blender is 50r / min, to obtain a uniformly mixed alloy powder.

[0052] Put the mixed alloy powder into a ball mill for ball milling. The ball mill speed is 100r / min. Molybdenum balls with a diameter of 10mm are placed in the ball mill. The mass ratio of molybdenum balls to alloy powder is 2:1, and the ball milling time is 24 hours.

[0053] The ball-milled powder is pressed into shape by molding method, the pressure is 100Mpa, and the holding time is 30s.

[0054] Then pre-sinter th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com