Magnetism, copper and zinc-iron soft magnetic ferrite material and preparation method thereof

A soft ferrite, magnesium-copper-zinc technology, applied in the field of soft ferrite materials and preparation, can solve the problems of characteristic attenuation, high mechanical strength, and large limitations of magnesium-zinc ferrite, and achieve high DC superposition characteristics, The effect of good mechanical strength, excellent high frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

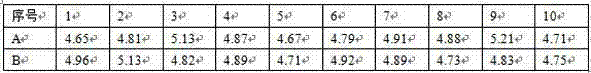

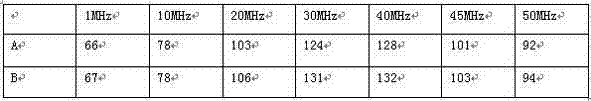

[0023] According to iron oxide: zinc oxide: magnesium oxide: copper oxide = 51.2:10:34.8:4 mol%, the main ingredients are mixed, and the additives are added according to the mass fraction, calcium carbonate 0.4, cobalt oxide 0.35 bismuth oxide 0.06. Mix the prepared materials in a vibration ball mill for 1 hour, pre-fire at 1050 ° C, keep warm for 3 hours, and then vibrate ball mill for 1 hour again after cooling. Add water to the sand mill, the slurry concentration is 65%, sand mill for 2 hours, add PVA solution, defoamer, dispersant, and spray granulate to obtain granules. Press T18*10*5, sinter at 1250°C, and hold for 4 hours. Get the finished magnetic core. Φ0.31 enameled wire 20 turns, test the Q value, and compare it with nickel-zinc ferrite with the same magnetic permeability, it can be seen that the two materials have similar frequency characteristics below 50MHz.

[0024] A is magnesium-zinc material B is a commonly used nickel-zinc material, and the magnetic permea...

Embodiment 2

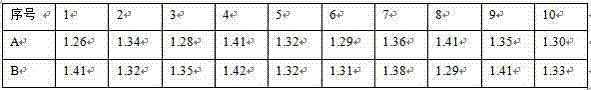

[0028] According to iron oxide: zinc oxide: magnesium oxide: copper oxide = 48.5:21.6:25.9: 4 mol%, the main ingredients are prepared, and the additives are added according to the mass fraction, vanadium pentoxide 0.2, cobalt oxide 0.35, bismuth oxide 0.12. The manufacturing process of granular material is the same as example 1. Press the I-shaped magnetic core 6*8 with the obtained pellets, sinter at 1250°C, and keep warm for 4 hours. Get the finished magnetic core. Φ0.12 enameled wire, 238.5 turns, 10K, 0.3V for inductance measurement. Comparison with the same core made of NiZn material. It can be seen that the DC superposition characteristics of the magnesium-zinc core and the nickel-zinc core are similar in mechanical strength.

[0029] A is magnesium-zinc material B is a commonly used nickel-zinc material, the magnetic permeability of both materials is 350

[0030]

[0031] A high DC superposition characteristic ΔB(Bs-Br) value is critical. The above-mentioned ma...

Embodiment 3

[0036] According to iron oxide: zinc oxide: magnesium oxide: copper oxide = 49.5:22:25:3.5 mol%, the main ingredients are mixed, and the additives are added according to the mass fraction, vanadium pentoxide 0.2, bismuth oxide 0.15,. The manufacturing process of granular material is the same as example 1. Press the rod-shaped magnetic core 4*15 with the obtained pellets, sinter at 1250°C, and keep the temperature for 4 hours. Get the finished magnetic core. Φ0.8 enameled wire, 13.5 turns, 1K, 1V for inductance measurement. Comparison with the same core made of NiZn material. It can be seen that the DC superposition characteristics of the magnesium-zinc core and the nickel-zinc core are similar in mechanical strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com