Three-section electric arc heating thrustor

An arc heating and thruster technology, which is applied in the field of three-stage arc heating thrusters and segmented arc heating thrusters, can solve problems such as poor welding performance, difficulty in long-term work, and large gap in thermal expansion coefficient, etc. To the temperature gradient, to avoid cost increase, to meet the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the design of the present invention, in accordance with the requirements of different parts of the thruster for materials, the high-temperature performance, structural strength, thermal conductivity, and welding performance are separately paid attention to, which reduces the difficulty of material selection, and can meet the temperature, thermal conductivity, strength, etc. of materials in different regions The physical performance requirements are met, and the overall welding requirements of the structure are met, and the engineering design of the thruster structure is realized.

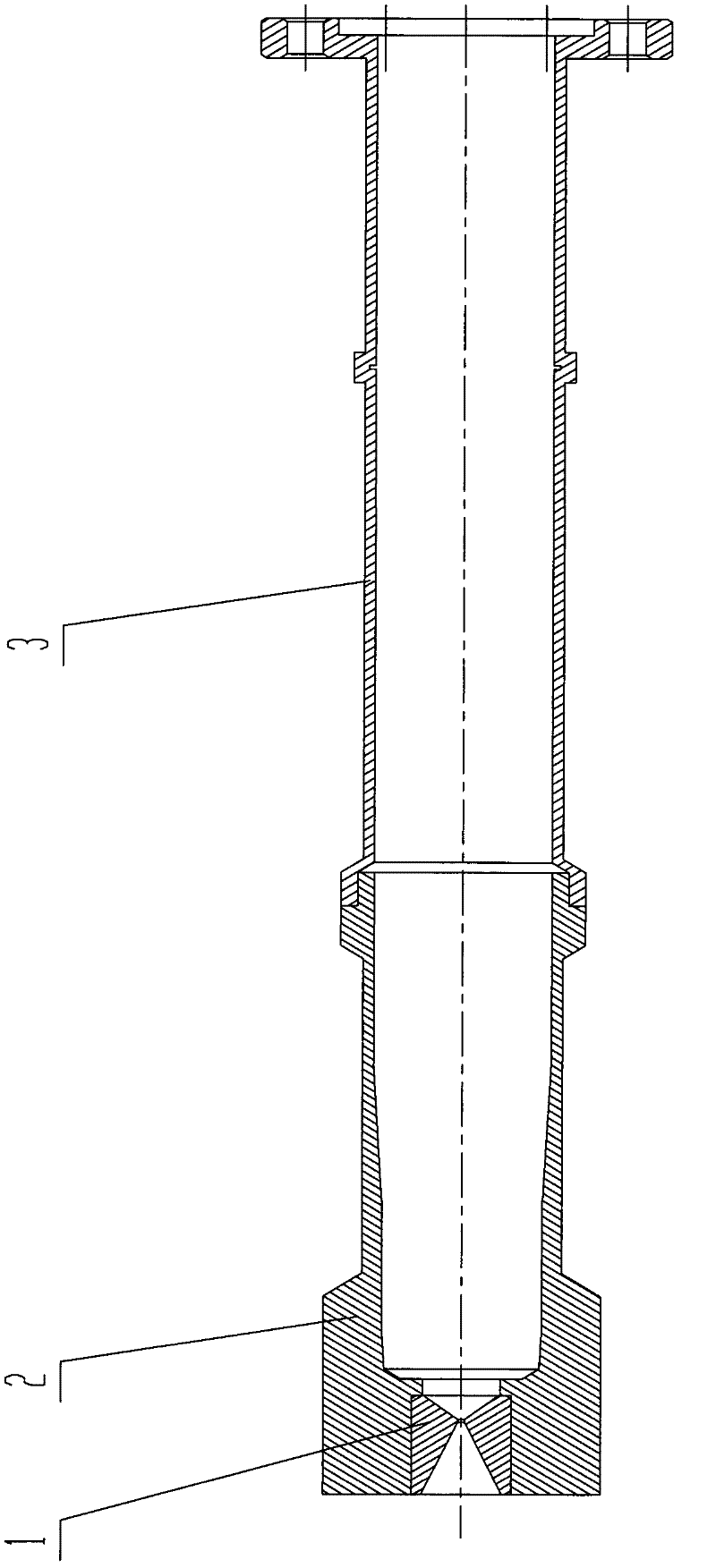

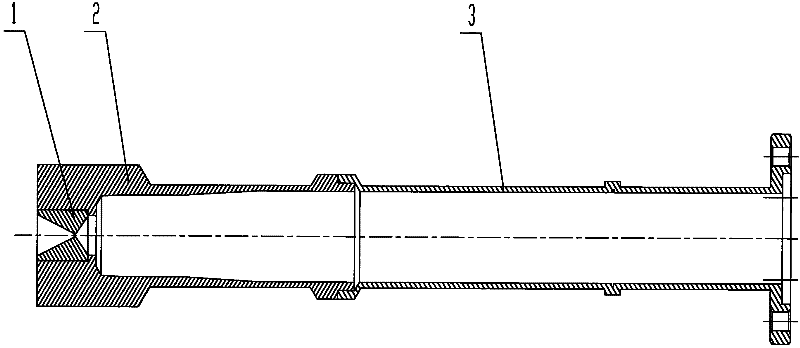

[0017] The invention is like figure 1 As shown, the segmented structure is divided into three sections, including anode section 1, transition section 2, and high thermal resistance section 3. The internal welding of one end of transition section 2 fixes anode section 1, and the other end of transition section 2 is welded to high thermal resistance section 3. Fixed to form a shell.

[0018] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com