Porous granular low carbon lime and production method thereof

A production method and granular technology, applied in the field of lime, can solve the problems of high activity, large lime porosity, prolonged heating time, etc., and achieve the effects of high early activity, high product quality, and fast calcination speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

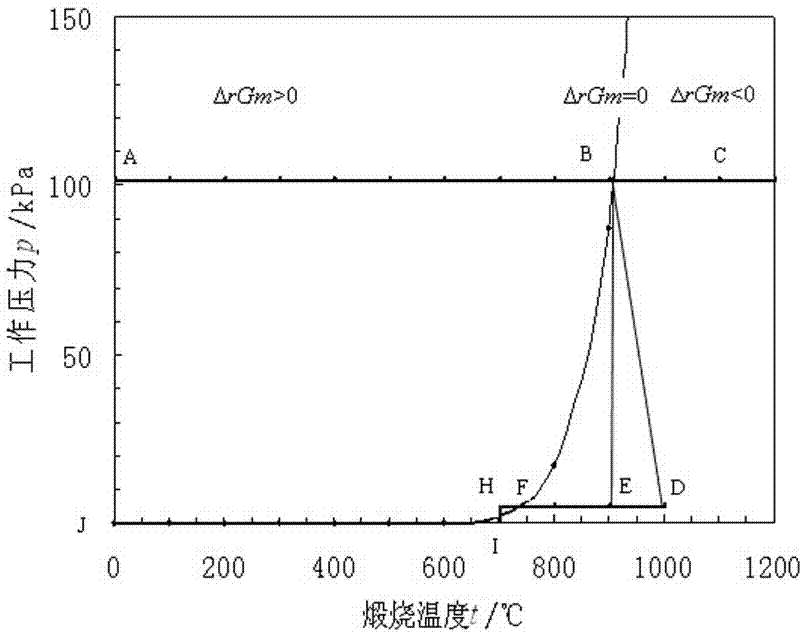

[0052] The embodiment of the present invention takes the vertical gas furnace with 17 nickel-chromium heat-resistant alloy tanks (arranged according to the number of 6-5-6) as an example, but the gas furnace is not a limitation of the present invention. The same goes for vertical gas stoves.

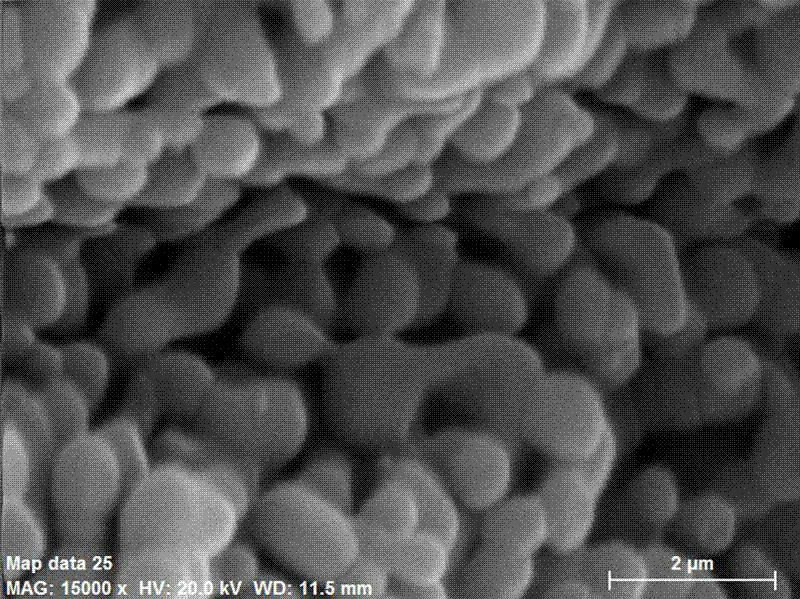

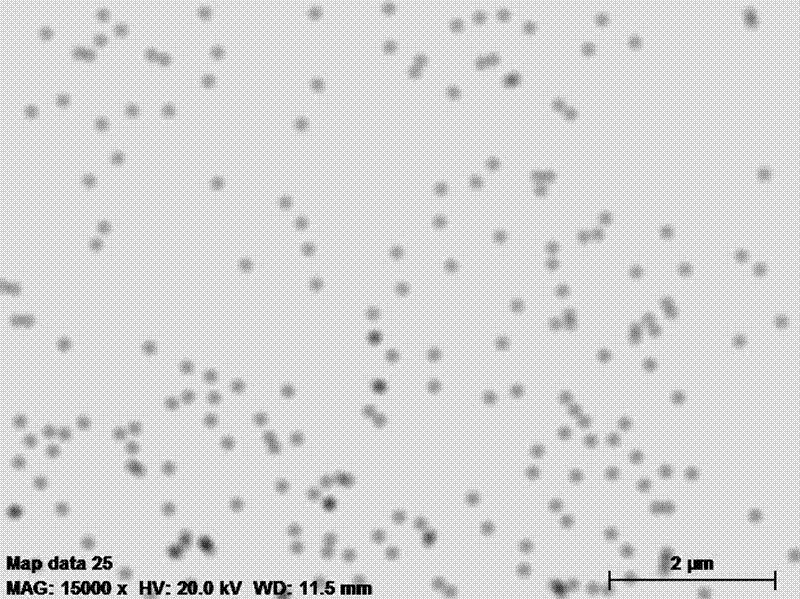

[0053] Select high-quality limestone particles with a particle size range of 5-10mm and a calcium oxide content of more than 54%, wash off the dust attached to the surface of the limestone particles, and then dry them.

[0054] According to the dryness of the limestone particles, 20-50% ferrous chloride or ferric chloride solution is selected to cover the limestone particles manually or mechanically, and then dry naturally.

[0055] Put the coated limestone particles into 17 nickel-chromium heat-resistant alloy tanks in the vertical gas furnace in sequence, cover the tank mouth with a heat shield, and pass cooling water into the tank mouth outside the furnace to raise the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com