Thermoplastic elastomer composition of encapsulation PETG (poly(ethylene terephthalate) glycol) and preparation method thereof

A technology of thermoplastic elastomer and composition, which is applied in the field of thermoplastic elastomer composition and its preparation of encapsulated PETG. Strong relay, strong grip and comfortable hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

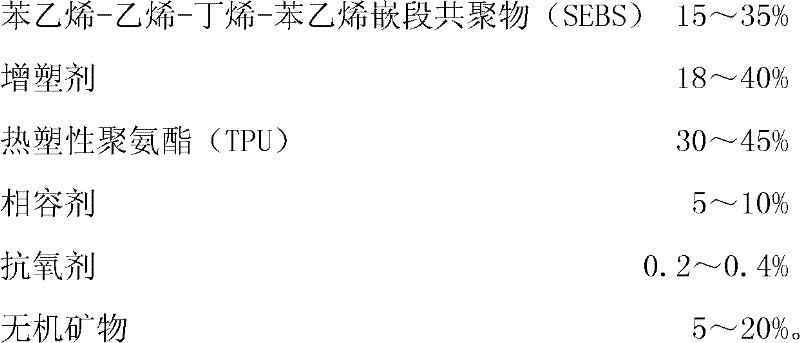

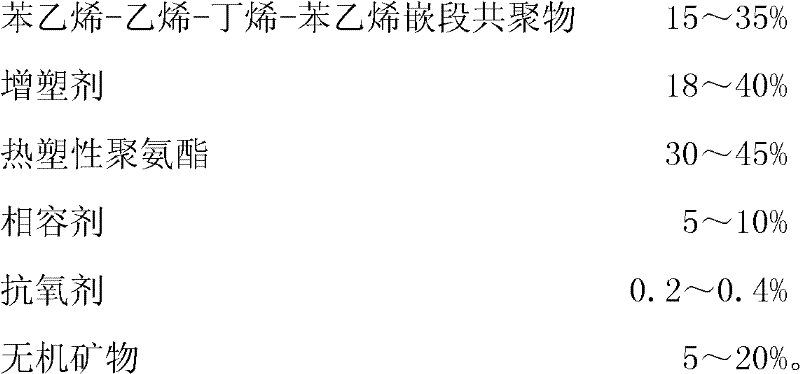

[0029] Among embodiments 1 to 4, SEBS is produced by Kraton Polymer Company, and its trade name is KRATON G1651; the plasticizer is the naphthenic oil produced by Karamay, Xinjiang, and its trade name is KN4010; TPU is the trade name of S85A10 produced by BASF; The compatibilizer is the ethylene-n-butyl acrylate-carbonyl copolymer produced by DuPont, the trade name is HP4051; Antioxidant is hindered phenolic antioxidant, specifically is the AO 1010 of Ciba Company; Inorganic mineral is the 800 order calcium carbonate that Anhui Hengda Calcium Carbonate Company produces, also can be superfine talcum powder, barium sulfate and its mixed.

[0030] Its preparation method is as follows:

[0031] (1) take raw materials by each component shown in Table 1 and the weight percentage content thereof;

[0032] (2) Mix SEBS and plasticizer in the above raw materials for 20 to 30 minutes in a high mixer;

[0033] (3) Add other raw materials and mix evenly, take out;

[0034] (4) Then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com