Polyformaldehyde composition with light stability

A polyoxymethylene composition and light-stabilizing technology, which is applied in the field of light-stabilized polyoxymethylene compositions, can solve the problems of easily forming cracks and pulverization on the surface, so as to improve the degree of photoaging, delay the yellowness index, and reduce the aging speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: The light-stable polyoxymethylene composition is prepared by the following ratio and method.

[0014] Raw material ratio: polyoxymethylene 100kg, calcium stearate 0.1kg, melamine 0.2kg, UVA-11 0.3kg; HALS-2 0.3kg.

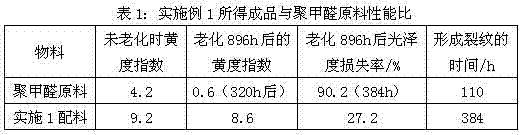

[0015] Preparation method: add the above raw materials into a high-speed mixer and mix them, use an injection molding machine to make a 2mm thick POM injection molded plate, and then test its photoaging according to SAE J2412 "Accelerated exposure of automotive interior parts with a xenon lamp device with controllable irradiance" Performance, test results and performance comparison of polyoxymethylene raw materials are shown in Table 1.

[0016]

Embodiment 2

[0017] Embodiment 2: The light-stable polyoxymethylene composition is prepared by the following ratio and method.

[0018] Raw material ratio: polyoxymethylene 100kg, calcium stearate 0.1kg, melamine 0.2kg, UVA-11 0.5kg, HALS-2 0.5kg.

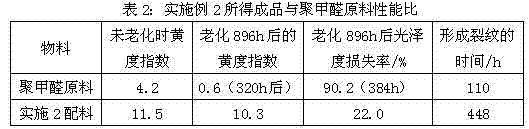

[0019] Adopt the method identical with embodiment 1 to make 2mm thick POM injection-molded plate, then according to SAE J2412 " use the xenon lamp device of controllable irradiance to carry out accelerated exposure to automotive interior parts " test its photoaging performance, its result and polyoxymethylene The performance comparison of raw materials is shown in Table 2.

[0020]

Embodiment 3

[0021] Embodiment 3: The light-stable polyoxymethylene composition is prepared by the following ratio and method.

[0022] Raw material ratio: polyoxymethylene 100kg, calcium stearate 0.2kg, polyamide 0.3kg, UVA-7 0.8kg, HALS-2 0.1kg.

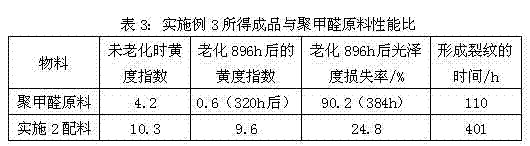

[0023] Adopt the method identical with embodiment 1 to make 2mm thick POM injection-molded plate, then according to SAE J2412 " use the xenon lamp device of controllable irradiance to carry out accelerated exposure to automotive interior parts " test its photoaging performance, its result and polyoxymethylene The performance comparison of raw materials is shown in Table 3.

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com