High-weather-resistance TPO waterproof coiled material as well as preparation method and application thereof

A technology of waterproof membrane and high weather resistance, which is applied to roofs, roofs, and roof coverings using flexible materials. It can solve problems such as complex preparation methods and achieve high weather resistance, photoaging inhibition, and high light, heat, and oxygen stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

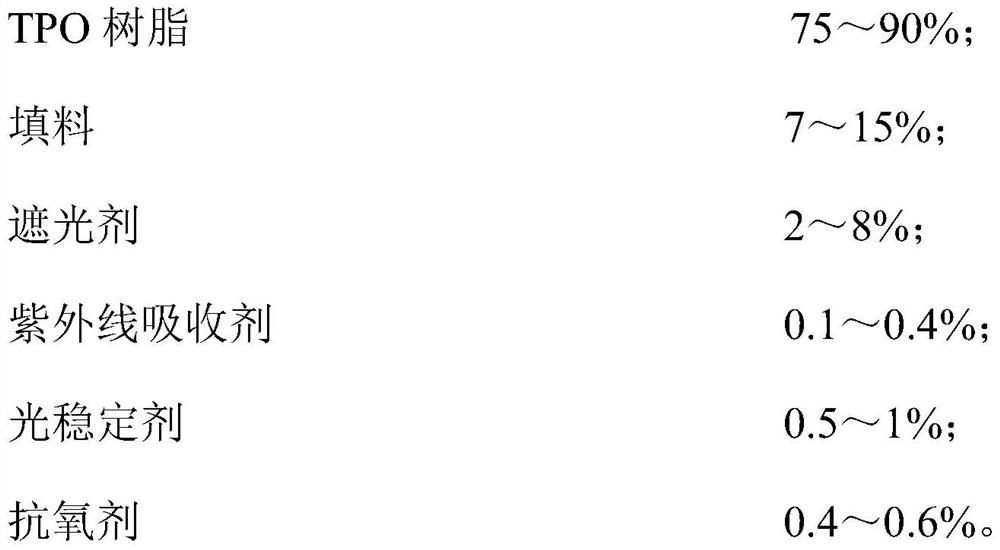

[0040]In this embodiment, a high weather resistance TPO waterproof membrane is provided, and the preparation raw materials of the high weather resistance TPO waterproof membrane include the following components in terms of weight percentage:

[0041]

[0042] Among them, the filler is active light calcium, the sunscreen is titanium dioxide, the ultraviolet absorber is UV328, the light stabilizer is light stabilizer 2020, and the antioxidant is B225.

[0043] The preparation method comprises the following steps:

[0044] (1) mix the resin CA10A and resin CA60A of formula quantity evenly, add in the twin-screw extruder from the main feeding port;

[0045] (2) Mix the fillers, opacifiers, ultraviolet absorbers, light stabilizers and antioxidants in the formula evenly, add them into the twin-screw extruder from the side feeding port, extrude them into shape, and then press them through a three-roller calender Light forming into sheets, cooling, and winding to obtain the high w...

Embodiment 2

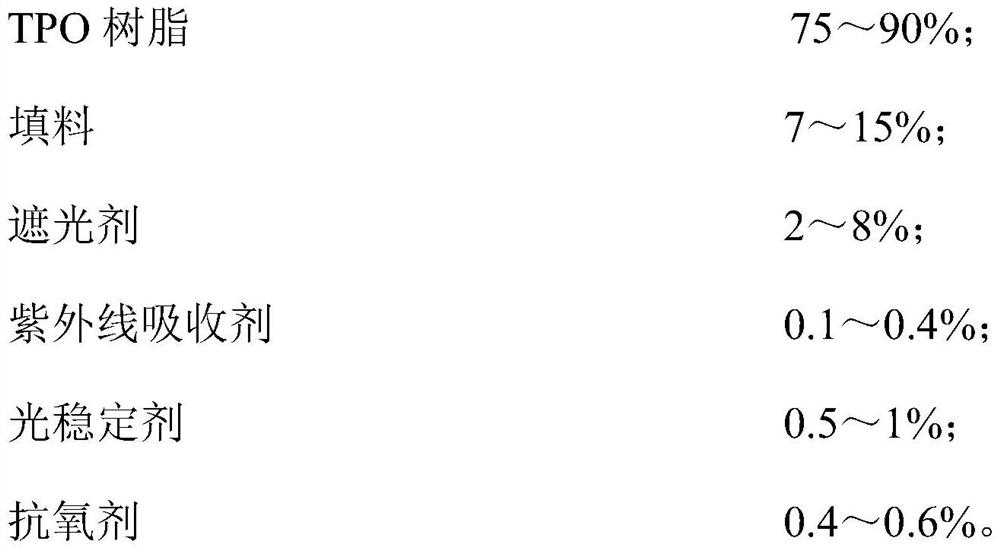

[0048] In this embodiment, a high weather resistance TPO waterproof membrane is provided, and the preparation raw materials of the high weather resistance TPO waterproof membrane include the following components in terms of weight percentage:

[0049]

[0050] Among them, the filler is active light calcium, the sunscreen is titanium dioxide, the ultraviolet absorber is UV326, the light stabilizer is light stabilizer 2020, and the antioxidant is B225.

[0051] The preparation method comprises the following steps:

[0052] (1) mix the resin CA10A and resin CA60A of formula quantity evenly, add in the twin-screw extruder from the main feeding port;

[0053] (2) Mix the fillers, opacifiers, ultraviolet absorbers, light stabilizers and antioxidants in the formula evenly, add them into the twin-screw extruder from the side feeding port, extrude them into shape, and then press them through a three-roller calender Light forming into sheets, cooling, and winding to obtain the high ...

Embodiment 3

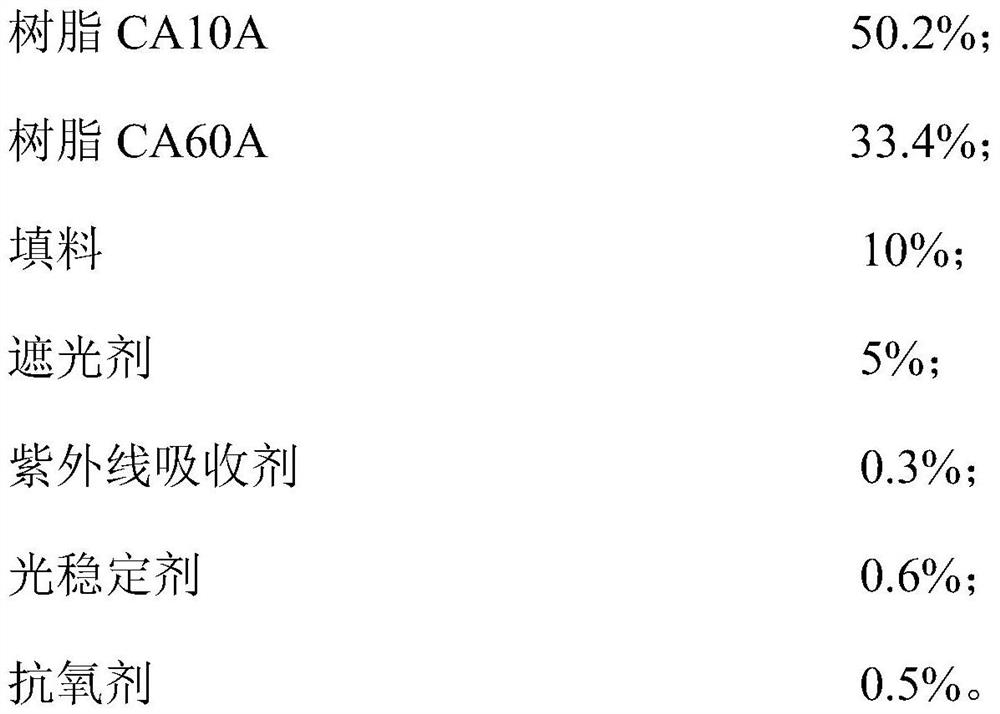

[0056] In this embodiment, a high weather resistance TPO waterproof membrane is provided, and the preparation raw materials of the high weather resistance TPO waterproof membrane include the following components in terms of weight percentage:

[0057]

[0058] Among them, the filler is active light calcium, the sunscreen is titanium dioxide, the ultraviolet absorber is UV328, the light stabilizer is light stabilizer 2020, and the antioxidant is B225.

[0059] The preparation method comprises the following steps:

[0060] (1) mix the resin CA10A and resin CA60A of formula quantity evenly, add in the twin-screw extruder from the main feeding port;

[0061] (2) Mix the fillers, opacifiers, ultraviolet absorbers, light stabilizers and antioxidants in the formula evenly, add them into the twin-screw extruder from the side feeding port, extrude them into shape, and then press them through a three-roller calender Light forming into sheets, cooling, and winding to obtain the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com