Yeast surface atom transfer imprinted adsorbent, and preparation method and application thereof

A technology of imprinted adsorption and atom transfer, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve problems that have not been reported, and achieve the effect of cheap price, good adsorption performance, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

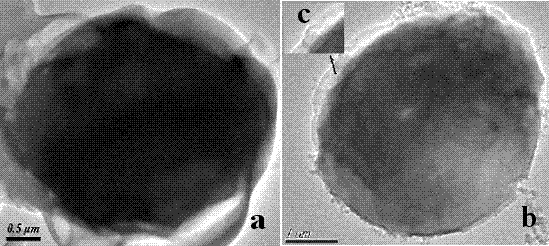

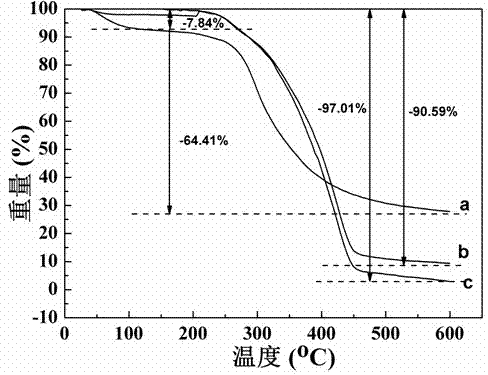

Image

Examples

Embodiment 1

[0025] (1) Preparation of yeast surface-loaded initiator

[0026] Add yeast to a mixture of thionyl chloride and benzene at a volume ratio of 50:10 (mL), wherein yeast and benzene are added at a mass-to-volume ratio of 1 g:10 mL, and react at 70°C After 24 h, wash three times with tetrahydrofuran, dry in vacuum at 25 ℃, take the dried product and disperse it in a mixed solution of tetrahydrofuran and anhydrous triethylamine with a volume ratio of 30:1 (mL). Water triethylamine is 1 g: 1 mL according to the mass and volume ratio, and isobutyryl bromide with a volume ratio of 1:1 (mL) to anhydrous triethylamine is added dropwise after passing nitrogen gas in an ice bath to evacuate oxygen. React at room temperature for 12 h, wash with ethanol three times, and vacuum-dry at 25 °C to obtain the yeast initiator.

[0027] (2) Preparation of yeast surface imprinted adsorbents (MIPs)

[0028]Add the template molecule cephalexin to the mixed solution of methacrylic acid and ethylene...

Embodiment 2

[0032] (1) Preparation of yeast surface-loaded initiator

[0033] Add yeast to a mixture of thionyl chloride and benzene at a volume ratio of 100:10 (mL), wherein yeast and benzene are added at a mass-to-volume ratio of 1.5 g:10 mL, and react at 80 °C 28 h, washed three times with tetrahydrofuran, dried under vacuum at 35 °C, and dispersed the dried product in a mixed solution of tetrahydrofuran and anhydrous triethylamine with a volume ratio of 40:1 (mL), wherein the dried product was mixed with no The water triethylamine is 1.5 g: 1 mL according to the mass and volume ratio, after passing nitrogen and evacuating oxygen in an ice bath , Add isobutyryl bromide with a volume ratio of 2:1 (mL) to anhydrous triethylamine dropwise, react at room temperature for 16 h, wash with ethanol three times, and vacuum-dry at 40 °C to obtain the yeast initiator.

[0034] (2) Preparation of yeast surface imprinted adsorbents (MIPs)

[0035] Add the template molecule cephalexin to the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com