Hydrophilic polyethersulfone with cardo alloy ultrafiltration membrane and preparation method thereof

A phenolphthalein-based polyarylene ether, ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membrane technology and other directions, can solve the problems of insufficient long-term stability of hydrophilicity, poor temperature resistance, etc. The effect of improving water resistance and anti-pollution ability, increasing hydrophilicity, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

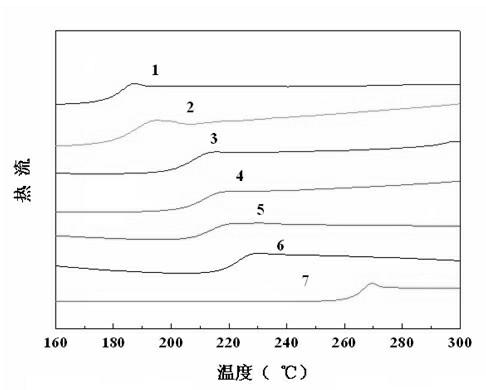

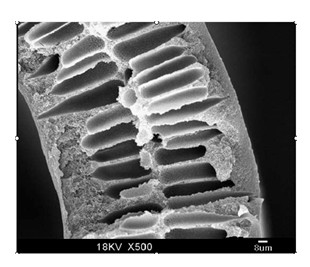

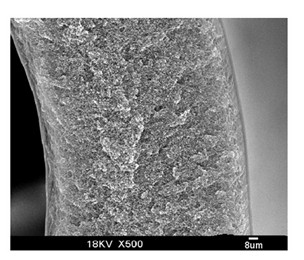

Method used

Image

Examples

Embodiment 1

[0062] 20 grams of phenolphthalein-based polyarylethersulfone PES-C, 3 grams of polyvinylpyrrolidone PVP (K90), were added to 95 grams of N-methylpyrrolidone, 2 grams of pure water and 1 gram of oxalic acid mixed solvent, stirred at 60 ° C for 24 Hours, a homogeneous blended polymer casting solution was formed. Thereafter, the casting solution was filtered through a stainless steel filter and placed in a material tank at a temperature of 60° C. for vacuum degassing. After the air bubbles are completely removed, use a glass scraper with a thickness of 200 microns to coat the casting solution on a glass plate, stay in the air for about 5 seconds, and then immerse in 40°C deionized water for phase separation and solidification to form a nascent super filter membrane. Thereafter, the membrane was soaked in deionized water at 25°C for 48 hours to set the shape, and was washed to remove residual solvents and additives. The cleaned membrane material is soaked in a hydrogen peroxide...

Embodiment 2

[0064] 20 grams of phenolphthalein-based polyarylethersulfone PES-C, 8 grams of polyvinylpyrrolidone PVP (K90), were added to 95 grams of dimethyl sulfoxide and 3 grams of polyethylene glycol (600) mixed solvent, stirred at 80 ° C for 36 Hours, a homogeneous blended polymer casting solution was formed. Thereafter, the casting solution was filtered through a stainless steel filter and placed in a material tank with a temperature of 80° C. for vacuum degassing. After the air bubbles are completely removed, use a stainless steel spatula with a thickness of 300 microns to coat the casting solution on a glass plate, stay in the air for about 10 seconds, and then immerse in 40°C deionized water for phase separation and solidification to form a nascent super filter membrane. Thereafter, the membrane was soaked in deionized water at 30°C for 24 hours to finalize the shape, and washed to remove residual solvents and additives. The cleaned membrane material was soaked in a sodium pers...

Embodiment 3

[0066] 16 grams of phenolphthalein-based polyarylethersulfone PES-C, 5 grams of polyvinylpyrrolidone PVP (K85), respectively added to 65 grams of N,N-dimethylformamide and 4 grams of polyethylene glycol (400) mixed solvent, in Stir at 80°C for 12 hours to form a homogeneous blended polymer casting solution. Thereafter, the casting solution was filtered through a stainless steel filter and placed in a material tank with a temperature of 80° C. for standing defoaming. After the air bubbles are completely removed, use a stainless steel scraper with a thickness of 250 microns to coat the casting solution on a glass plate, stay in the air for about 5 seconds, and then immerse in 40°C deionized water for phase separation and solidification to form a nascent super filter membrane. Thereafter, the membrane was soaked in deionized water at 25°C for 48 hours to set the shape, and was washed to remove residual solvents and additives. The cleaned membrane material is soaked in a potassi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com