Post-treatment method of chinlon superfine denier fiber fabric

A technology of fiber fabric and nylon, which is applied in the post-processing field of nylon ultrafine denier fabric, and can solve the problems of low hydrostatic pressure resistance value of nylon ultrafine denier fabric, insufficient crispness of clothes, and low tear resistance strength, etc. , to achieve good tear resistance, reduce diffuse reflection, and good hydrostatic pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The base fabric is made of nylon superfine denier fiber. The warp and weft yarns of the base fabric are made of 20D / 24F nylon superfine denier filaments, and the warp and weft density is 720×680 / 10cm; the square meter weight is 56g / m 2 . Post-processing proceeds as follows:

[0052] 1. Desizing: use open width desizing machine. The temperature of the desizing tank is 98°C; the running speed of the fabric is 30m / min, and the processing time is 3min.

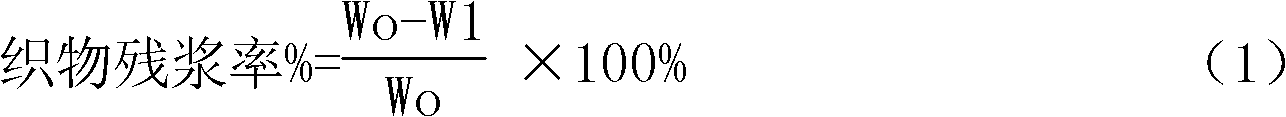

[0053] The formula of the treatment solution is based on the mass of each component per liter of water: liquid caustic soda 240g / L, refining agent 50g / L, penetrant 16g / L, chelating dispersant 8g / L. After desizing treatment, the residual size rate is 1.7%.

[0054] 2. Calendering treatment: High-temperature and high-pressure double-roll calender is used, the fabric running speed is 35m / min, and the pressure is 80kg / m 2 , the temperature is 160°C.

[0055] 3. Coating finishing: Floating knife coating at room temperature...

Embodiment 2

[0061] 1. Desizing: use open width desizing machine. The temperature of the desizing tank is 100°C; the running speed of the fabric is 27m / min. The formula of the treatment liquid is based on the mass of each component per liter of water: liquid caustic soda 260g / L, penetrant 19g / L, refining agent 55g / L, chelating dispersant 10g / L. After desizing treatment, the residual pulp rate is 1.1%

[0062] 2. Calendering treatment: high temperature and high pressure calendering machine is adopted, the fabric running speed is 30m / min, and the pressure is 100kg / m 2 The temperature was 170°C.

[0063] 3. Coating finishing: Floating knife coating at room temperature is adopted, the fabric running speed is 25m / min, and the baking temperature is 170°C. The front side of the cloth is coated with finishing agent A, and the reverse side of the cloth is coated with finishing agent B.

[0064] The components of the finishing solution and their contents in parts by weight are: finishing agent A...

Embodiment 3

[0068] 1, desizing: with embodiment 2. The residual pulp rate after desizing treatment is 1.2%

[0069] 2. Calendering treatment: high temperature and high pressure calendering machine is adopted, the fabric running speed is 23m / min, and the pressure is 90kg / m 2 , the temperature is 168°C.

[0070] 3. Coating finishing: the fabric running speed is 32m / min, and the baking temperature is 165°C.

[0071] The components of the finishing liquid and their contents in parts by weight are: finishing agent A has a viscosity of 20000 cps and 88 parts of polyurethane resin with a solid content of 31%; solvent A is 6 parts of dimethylformamide; 4 parts of isocyanate; 1 part of hypophosphorous acid parts; 1 part of titanium dioxide. Finishing agent B: 84 parts of organopolysiloxane and hydrophilic polysiloxane resin mixture; Solvent B: 11 parts of toluene; 2 parts of isocyanate; 3 parts of sodium dihydrogen phosphate.

[0072] The preparation process of the finishing liquid is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com