Water-blush-resistant fluoride and siloxane modified waterborne pressure-sensitive adhesive and polyethylene protective film

A polyethylene protective film and fluorine-silicon modification technology, which is applied in the direction of adhesives, ester copolymer adhesives, film/sheet adhesives, etc., can solve the problem of water-whitening resistance without the double modification method of fluorine-silicon Insufficient, shortened pot life of glue, etc., to alleviate the problem of coating film migration, reduce the possibility of water absorption and whitening, and improve the effect of water whitening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

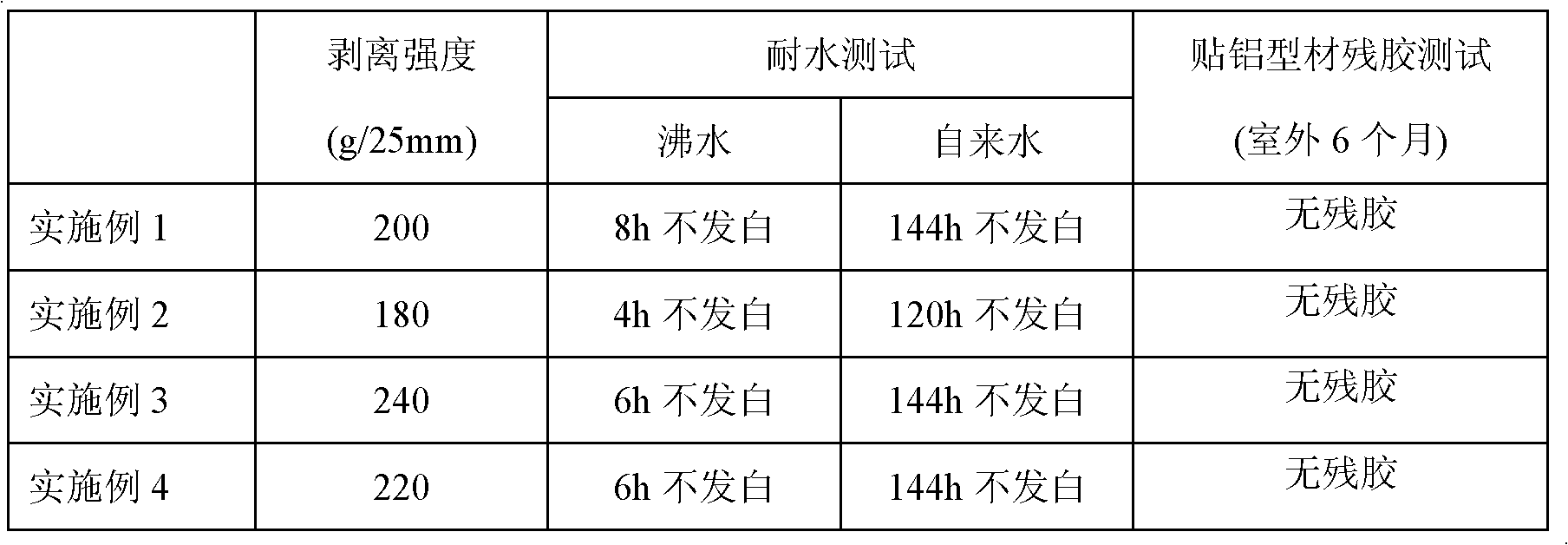

Examples

Embodiment 1

[0030] Prepare the water-resistant whitening fluorosilicon modified water-based pressure-sensitive adhesive according to the following specific steps:

[0031](1) Add 60 parts by weight of deionized water, 0.5 parts by weight of sodium alkylamide ethylene sulfonate (DNS-86), and 0.5 parts by weight of sodium vinyl sulfonate (SVS) into a three-necked flask, and use 800 rpm Stir at a stirring speed of 1 / min and stir evenly, then slowly mix 5 parts by weight of methyl methacrylate, 93 parts by weight of isooctyl acrylate, 75 parts by weight of butyl acrylate, 10 parts by weight of hexafluorobutyl acrylate, 10 parts by weight of Parts of γ-methacryloxypropyl tris (isopropoxy) silane, 3 parts by weight of hydroxyethyl acrylate, 4 parts by weight of acrylic acid, 0.5 parts by weight of ethylene glycol dimethacrylate, 0.1 parts by weight Parts of n-dodecyl mercaptan are added dropwise, and stirred to obtain the pre-emulsion for subsequent use for 30 minutes;

[0032] (2) Add 160 par...

Embodiment 2

[0041] Prepare the water-resistant whitening fluorosilicon modified water-based pressure-sensitive adhesive according to the following specific steps:

[0042] (1) Add 60 parts by weight of deionized water and 0.5 parts by weight of allyloxy fatty alcohol polyoxyethylene ether ammonium sulfate (SR-10) into a three-necked flask, stir evenly at a stirring speed of 800 rpm, Then slowly add 10 parts by weight of methyl methacrylate, 88 parts by weight of isooctyl acrylate, 85 parts by weight of butyl acrylate, 5 parts by weight of nonadecafluoromethacrylate, 3 parts by weight of vinyltrimethoxy 3 parts by weight of hydroxypropyl acrylate, 4 parts by weight of acrylic acid, 2 parts by weight of glycidyl methacrylate, 0.2 parts by weight of trimethylolpropane trimethacrylate, 0.3 parts by weight of mercaptoethanol Drop in and stir for 30 minutes to obtain a pre-emulsion and set aside;

[0043] (2) the step (1) gained pre-emulsion of the deionized water of 160 weight parts, the sodi...

Embodiment 3

[0052] Prepare the water-resistant whitening fluorosilicon modified water-based pressure-sensitive adhesive according to the following specific steps:

[0053] (1) 60 parts by weight of deionized water, 0.7 parts by weight of sodium alkylamide ethylene sulfonate (DNS-86), 0.8 parts by weight of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate (SE-10 ) into a three-necked flask, stir evenly at a stirring speed of 600 rpm, then slowly mix 20 parts by weight of methyl acrylate, 50 parts by weight of ethyl acrylate, 104 parts by weight of isooctyl acrylate, 6 parts by weight of Hexafluorobutyl acrylate, 8 parts by weight of γ-methacryloxypropyl tri(methoxy)silane, 4 parts by weight of hydroxyethyl methacrylate, 5 parts by weight of acrylic acid, 3 parts by weight of hydroxyl Methacrylamide, 0.8 parts by weight of ethylene glycol dimethacrylate, and 0.1 parts by weight of n-dodecyl mercaptan are added dropwise, and stirred for 30 minutes to obtain a pre-emulsion, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com