Nitragin controlled release fertilizer special for alfalfa, and preparation and application of nitragin controlled release fertilizer

A rhizobia agent and controlled-release fertilizer technology, applied in the field of leguminous forage controlled-release fertilizer, can solve the problems of low overwintering rate of alfalfa, lack of labor force, low yield, etc., and achieve the effects of increasing alfalfa yield and improving inoculation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

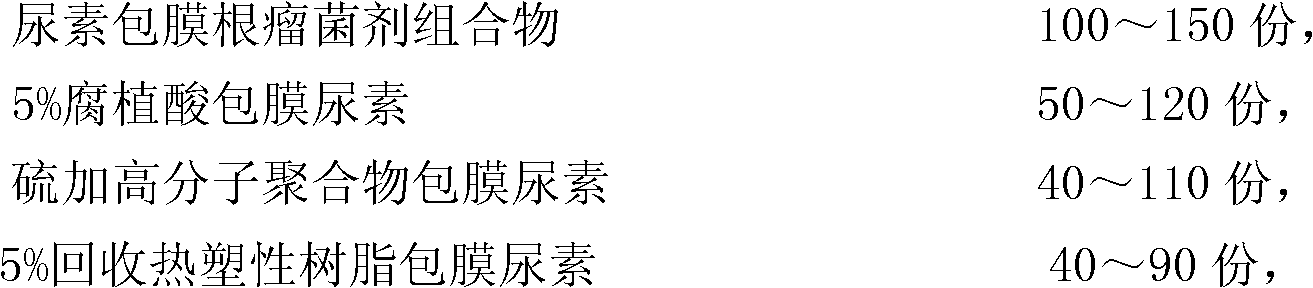

[0042] Embodiment 1: special rhizobia agent controlled release fertilizer for alfalfa, raw material components are as follows:

[0043]

[0044] Preparation:

[0045] (1) Preparation of urea-coated rhizobia agent composition:

[0046] A, prepare rhizobia fermented liquid:

[0047] According to the prior art, the Sinorhizobium meliloti ACCC17665 strain was cultured and activated with mannitol-yeast powder slant medium at 28°C to 30°C for 3 days, and it was observed that the slant was plump, the surface was moist and smooth, and it was mucus-like. When it is colorless and transparent, it is used as an activated strain for the next liquid culture. The formula of the mannitol-yeast powder slant medium is: 14.5 grams of mannitol, 5.2 grams of yeast powder, 0.4 grams of potassium dihydrogen phosphate, 0.1 grams of magnesium sulfate, 0.3 grams of sodium chloride, 0.5 grams of calcium chloride, and 15 grams of agar. grams, 1000 grams of water.

[0048] Take 200 grams of bean sp...

Embodiment 2

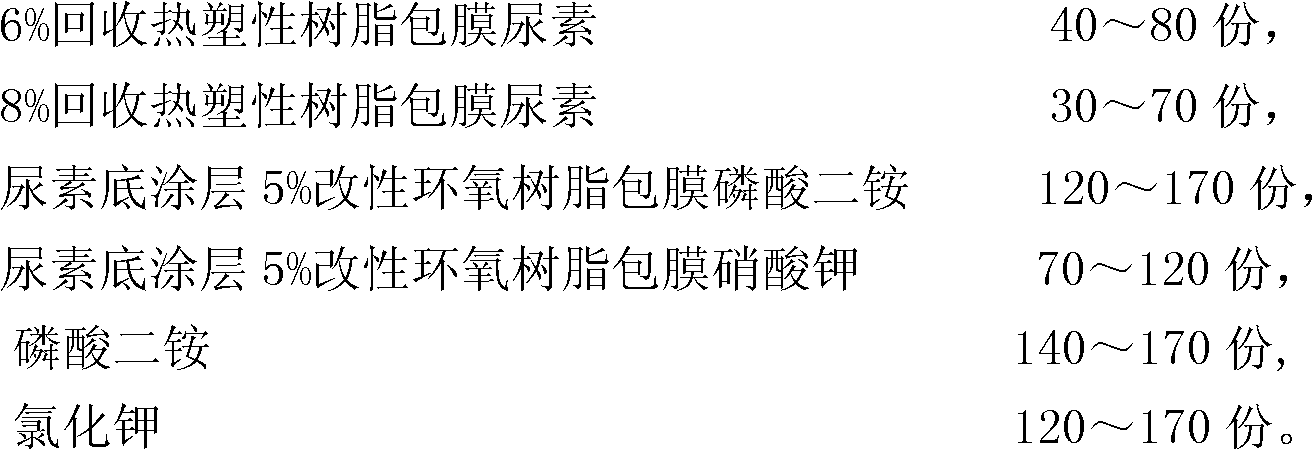

[0054] Embodiment 2: special rhizobia agent controlled release fertilizer for alfalfa, raw material components are as follows:

[0055]

[0056] The preparation method is the same as in Example 1.

Embodiment 3

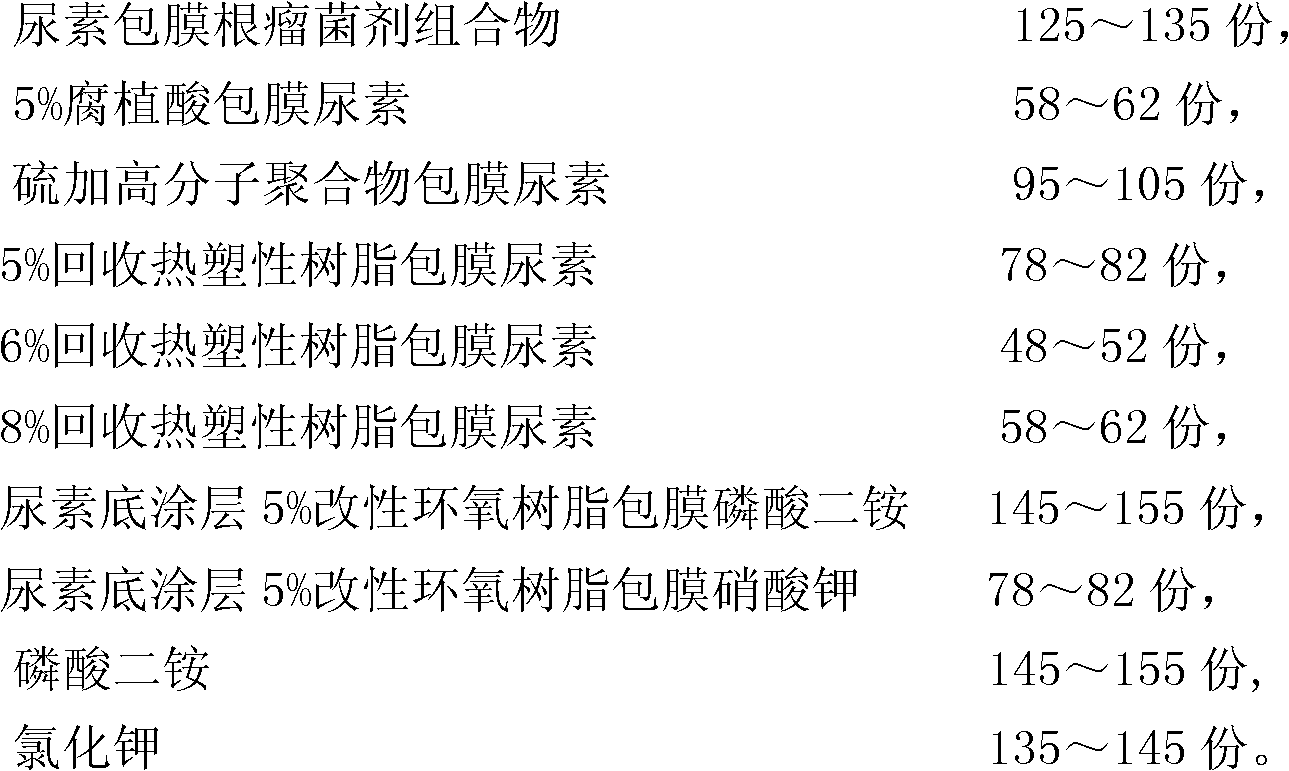

[0057] Embodiment 3: special rhizobia agent controlled release fertilizer for alfalfa, raw material components are as follows:

[0058]

[0059] Preparation:

[0060] (1) Preparation of urea-coated rhizobia agent composition:

[0061] A. The preparation of the fermentation broth of Sinorhizobium meliloti ACCC17665 was the same as in Example 1.

[0062] B. Get 40 kg of fermented liquid and add it into 140 kg of sterilized peat soil, and mix thoroughly.

[0063] C, get 5.5 kilograms of ferrous sulfate and 2.8 kilograms of ammonium molybdates and add in the mixture prepared in step B, mix well.

[0064] D. Transfer the mixture prepared in step C into a disc granulator for granulation, the drying temperature is 40°C-50°C, the particle size is 2-4 mm, and the water content of the finished granules is 29.1%.

[0065] E. Take 13.5 kg of urea and put it into the urea melter, quickly melt it into urea liquid, use the pressure pump to spray the urea liquid through the nozzle to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com