Method for preparing ceramic coating on surface of porous ceramic substrate

A technology for porous ceramics and ceramic coatings, which is applied in the field of preparing ceramic coatings on the surface of porous ceramic substrates, and can solve the problems of low deposition efficiency, difficult industrial application of ceramic coatings on porous ceramic surfaces, and cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

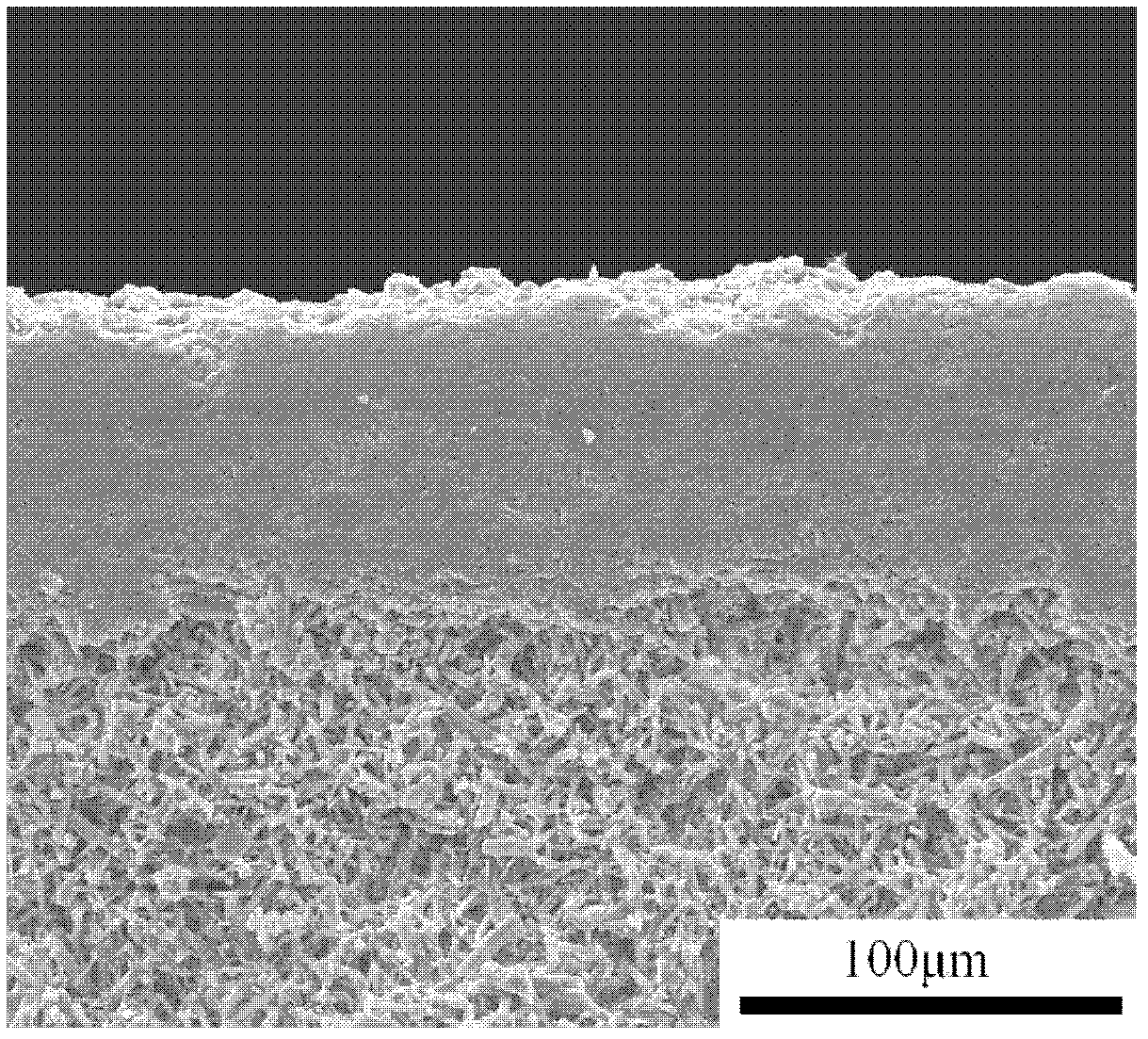

[0021] Such as figure 1 As shown, a method for preparing a ceramic coating on the surface of a porous ceramic substrate in this embodiment comprises the following steps:

[0022] Step 1: First select the phase composition as β-Si 3 N 4 , with a porosity of 57%, a water absorption rate of 40.1%, and a microhardness of 464.52HV, sintered porous silicon nitride was used as the substrate, and then sandpaper with mesh numbers of 400 mesh, 800 mesh, and 1000 mesh was selected to fine-tune the porous ceramic substrate successively. grind;

[0023] Step 2: Put the finely ground porous silicon nitride substrate into absolute ethanol for ultrasonic cleaning for 30 minutes;

[0024] Step 3: put the cleaned porous ceramic substrate into an oven for 15 hours and dry at 70°C;

[0025] Step 4: Select α-Al with a particle size of 15-45 μm 2 o 3 The powder is used as the raw material for spraying, and the supersonic plasma spraying method is used to prepare Al on the surface of the porou...

Embodiment 2

[0028] Such as figure 1 As shown, a method for preparing a ceramic coating on the surface of a porous ceramic substrate in this embodiment comprises the following steps:

[0029] Step 1: First select the phase composition as β-Si 3 N 4 , with a porosity of 57%, a water absorption rate of 40.1%, and a microhardness of 464.52HV, sintered porous silicon nitride was used as the substrate, and then sandpaper with mesh numbers of 400 mesh, 800 mesh, and 1000 mesh was selected to fine-tune the porous ceramic substrate successively. grind;

[0030] Step 2: Put the finely ground porous silicon nitride substrate into absolute ethanol for ultrasonic cleaning for 30 minutes;

[0031] Step 3: put the cleaned porous ceramic substrate into an oven for 15 hours and dry at 70°C;

[0032] Step 4: Select α-Al with a particle size of 15-45 μm 2 o 3 The powder is used as the raw material for spraying, and the supersonic plasma spraying method is used to prepare Al on the surface of the porou...

Embodiment 3

[0035] Such as figure 1 As shown, a method for preparing a ceramic coating on the surface of a porous ceramic substrate in this embodiment comprises the following steps:

[0036] Step 1: First select the phase composition as β-Si 3 N 4 , with a porosity of 40%, a water absorption rate of 25.4%, and a microhardness of 876.16HV, the sintered porous silicon nitride is used as the substrate, and then sandpaper with a mesh number of 400 mesh, 800 mesh, and 1000 mesh is used to fine-tune the porous ceramic substrate successively. grind;

[0037] Step 2: Put the finely ground porous silicon nitride substrate into absolute ethanol for ultrasonic cleaning for 20 minutes;

[0038]Step 3: put the cleaned porous ceramic substrate into an oven for 10 hours and dry at 70°C;

[0039] Step 4: Select α-Al with a particle size of 15-45 μm 2 o 3 The powder is used as the raw material for spraying, and the supersonic plasma spraying method is used to prepare Al on the surface of the porous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com