Establishing method and use of flue-cured tobacco GC/MS fingerprint

A technology of fingerprint spectrum and establishment method, applied in the field of tobacco quality grading, can solve problems such as no patent application in the application field, and achieve the effects of improving production level and economic benefit, good baseline separation, and high peak responsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

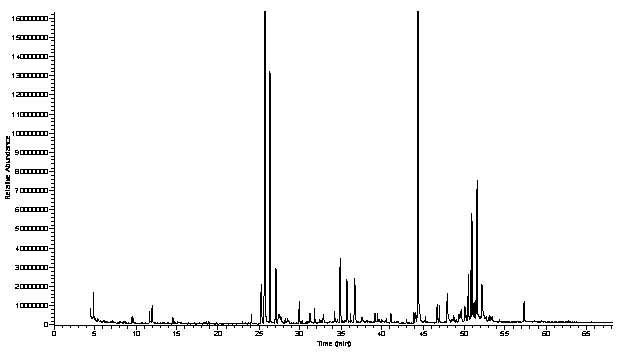

Method used

Image

Examples

Embodiment 1

[0031] A method for establishing a flue-cured tobacco GC / MS fingerprint of the present invention is realized through the following steps:

[0032] 1) Preparation of the solution to be tested: Connect a 500mL flat-bottomed flask to one end of the distillation extraction device, put 20.00g of tobacco powder into the flat-bottomed flask, add 350mL of pure water and 0.3mL of phenylethyl propionate with a concentration of 4μL / mL, and heated with an electric heating mantle that can control the voltage; connect a 100mL flask to the other end of the distillation extraction device, put 50mL of dichloromethane in the flask, place the flask on a water bath for heating, and distill at 56°C. Extract for 2.5 hours, remove the 100mL flask, add 5g of anhydrous sodium sulfate to it, seal it overnight, then put it into a rotary evaporator to concentrate to 1mL, pass through a 0.45μm filter membrane, and the filtrate is the solution to be tested;

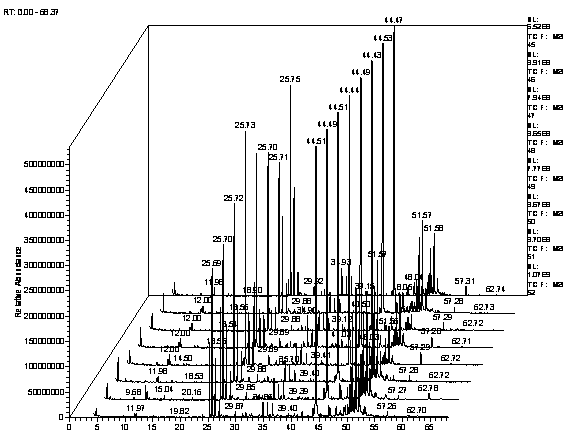

[0033] 2) Acquisition of flue-cured tobacco GC / ...

Embodiment 2

[0037] The tested tobacco variety K326, grade C3F, was obtained from 15 different tobacco leaf producing areas in Yunnan Province. All the tobacco samples were collected in 2009 and made into shredded tobacco after uniform redrying. Cut tobacco samples were dried at 40°C, pulverized with a plant grinder, passed through a 60-mesh sieve, sealed with a plastic bag, and stored in an ultra-low temperature refrigerator (-80°C) for testing. The determination method is as follows:

[0038] 1) Preparation of the solution to be tested: Connect a 500mL flat-bottomed flask to one end of the distillation extraction device, put 20.00g of tobacco powder into the flat-bottomed flask, add 450mL of pure water and 0.6mL of phenylethyl propionate with a concentration of 4μL / mL, And heat the flat-bottomed flask with a voltage-controllable electric heating mantle; connect a 100mL flask to the other end of the distillation extraction device, put 80mL of dichloromethane in the flask, place the flask ...

Embodiment 3

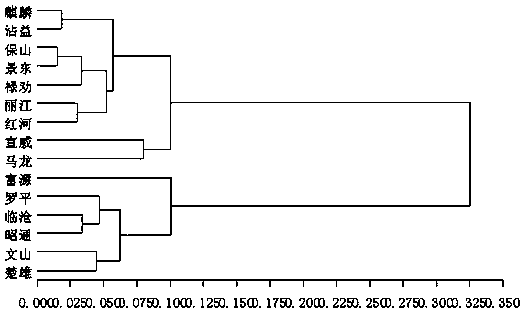

[0043] The tested tobacco variety K326, with a grade of B2F, was obtained from 17 different tobacco leaf producing areas in Yunnan Province. Analyze according to the preparation method and analysis method of Example 1, draw the clustering diagram of different samples ( Figure 4 ).

[0044] by cluster analysis Figure 4 It can be seen that when the distance is about 0.05, the B2F grade tobacco leaves of various production areas in Yunnan Province in 2009 can be divided into 6 categories: the first category of tobacco leaf production areas is Shizong, Luoping, Honghe; the second category is Puer, Wenshan, Lu Liang, Lincang; the third category is Dali, Zhaotong, Baoshan; the fourth category is Xundian, Chuxiong, Fuyuan, Zhanyi; the fifth category is Qilin, Yuxi; and Fuyuan is the sixth category.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com