Aeromonas capable of removing hydrogen sulfide (H2S) gas in gas and usage thereof

An Aeromonas, gas technology, applied in bacteria, air quality improvement, microorganism-based methods, etc., can solve the problems of low effective microorganism ratio and difficult control of operating conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Remove H from the gas 2 The method for isolating and cultivating the Aeromonas Aeromonas sp. of S gas comprises the steps:

[0017] (1) Sludge was taken from Tianjin Jizhuangzi Sewage Treatment Plant, supplemented with nutrient solution and aerated every day to make SVI above 90mL / g, and complete microbial culture. Stop adding the nutrient solution, add sodium thiosulfate aqueous solution (sulfur ion concentration is 2g / L) every day, keep ventilation, and after 15 days, the desulfurization bacteria become the dominant strain, and the desulfurization bacteria are domesticated.

[0018] Nutrient solution composition: glucose 0.1g, peptone 0.5g, K 2 HPO 4 0.6g, KH 2 PO 4 0.6g, MgCl 2 6H 2 O0.1g, NH 4 Cl 0.2g, a small amount of FeSO 4 7H 2 O and MgSO 4 -5H 2 O, add distilled water to 1000mL.

[0019] (2) Take out 10mL of the mud-water mixture obtained in step (1), add it into an Erlenmeyer flask equipped with 90mL sterilized distilled water and 20 sterilized ...

Embodiment 2

[0024] Aeromonas Aeromonas sp. of the present invention has the following microbiological characteristics:

[0025] 1. Morphological properties

[0026] Observed under a microscope, it is rod-shaped, 2.0 μm long and 0.62 μm wide; milky white colonies are formed on the culture medium.

[0027] 2. Cultivation characteristics

[0028] The (Aeromonas sp.) strain of the present invention has the following properties when cultured in a solid medium at 10°C.

[0029] The surface is smooth and wet, the surface is convex, the edge is jagged, the fungus is round, and the color is beige.

[0030] 3. Physiological characteristics

[0031] Gram-negative bacteria, catalase negative, methyl red test positive, hydrolyzed starch, liquefied gelatin, no indole production, growth pH 6-8, growth temperature 5-30°C.

[0032] According to the above-mentioned microbiological characteristics, it was named as Aeromonas sp., and it was preserved in the General Microbiology Center of China Committee ...

Embodiment 3

[0034] Aeromonas sp. to gas H 2 S gas removal effect.

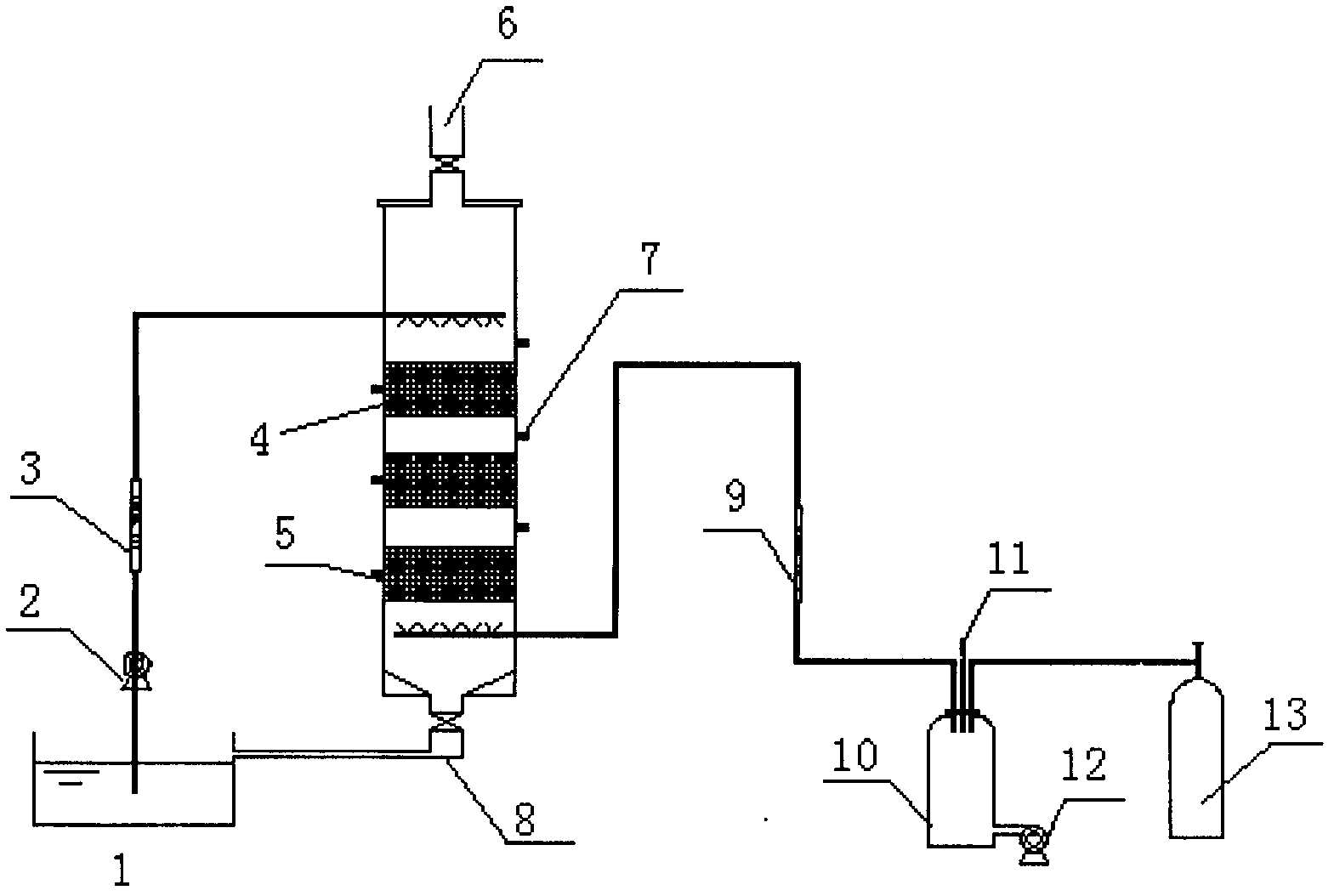

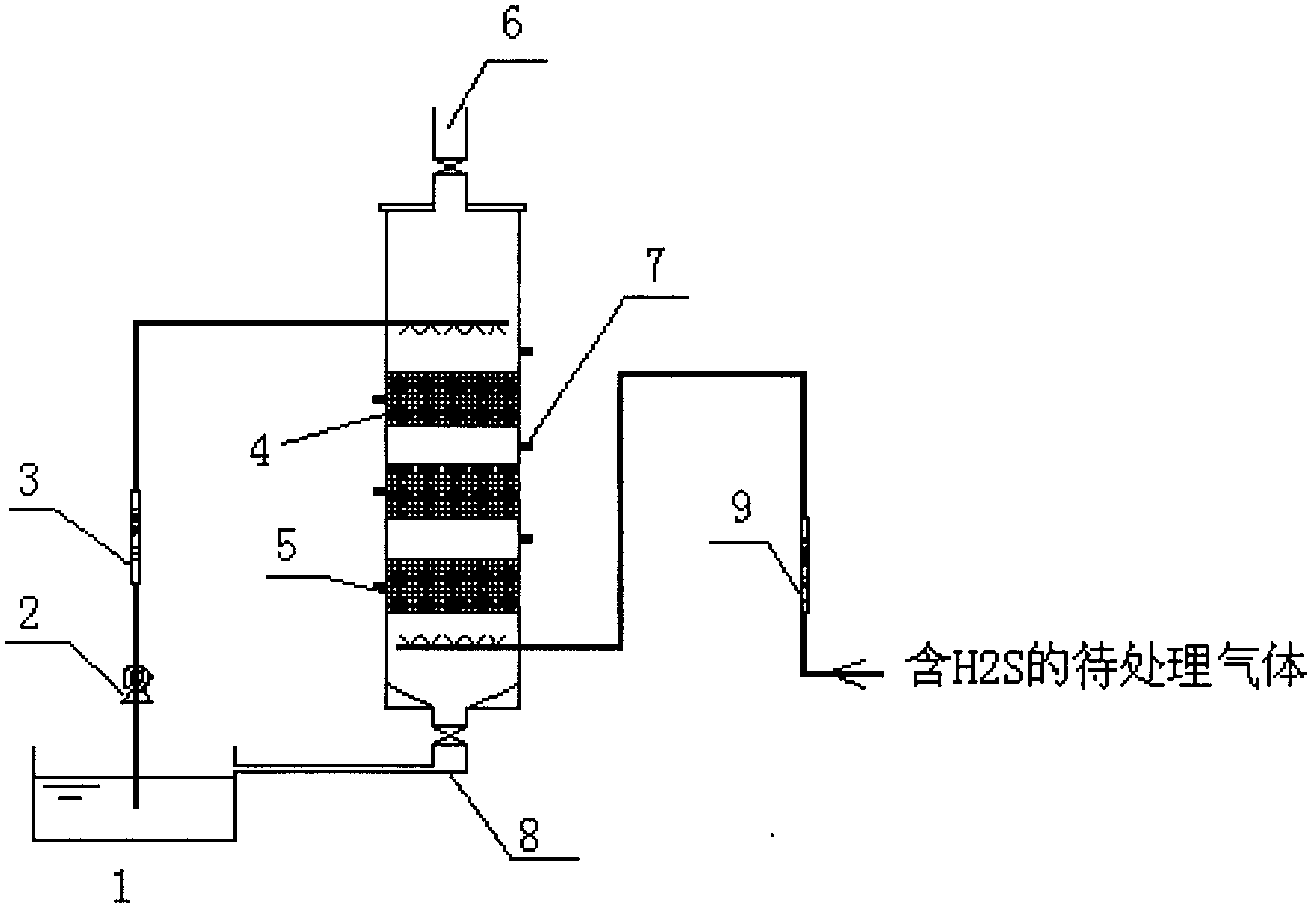

[0035] The selected Aeromonas (Aeromonas sp.) was inoculated into the culture medium for expanded culture to form a bacterial suspension; the ceramsite filter material was soaked in it, the culture medium was added every day and aeration was continued, and the organisms on the surface of the filter material When the thickness of the membrane reaches 1-2m, the membrane hanging is completed; the filter material with the membrane hanging is added to the biological trickling filter layer by layer (see figure 1 ), when the spray liquid flow rate is 8L / h and contains H 2 S air flow 0.4m 3 / h, where H 2 S mass concentration 0.2~0.25mg / m 3 , Start the device under the process conditions of room temperature. Wait for H 2 The removal rate of S has reached more than 85%, and the outlet mass concentration is controlled at 0.03mg / m 3 Below, it indicates that the biotrickling filter unit has been started and has entered a stable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com