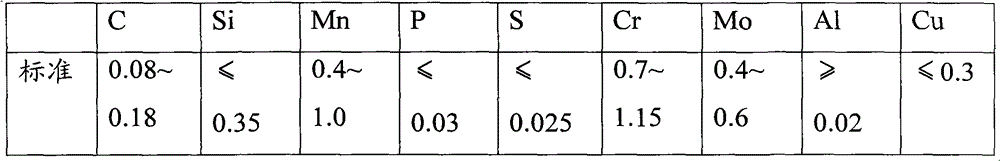

Cold-rolled steel strip and production method thereof, and anode plate material for electric dust removing device

A technology for a cold-rolled steel strip and a production method, which are applied in the field of anode plate materials for steel-making electrostatic precipitators and the production process thereof, can solve problems such as poor annealing uniformity, residual emulsion oxidation, etc., achieve simple production equipment, and improve surface roughness. , the effect of preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The hot-rolled coil blank used in this embodiment is 13CrMo44 steel grade, purchased from Shanxi Taigang Stainless Steel Co., Ltd. In the embodiment, the size of the hot-rolled coil billet is 3.5mm*1150mm, and the length is determined according to the needs. Yield strength 380MPa, tensile strength 500MPa, elongation 30%.

[0076] In this embodiment, four pickling tanks are used for pickling, using hydrochloric acid solution as the pickling liquid, the pickling speed is: 20m / min, and the conventional ion titration method is used to control Fe +2 ≤160mg / L, if Fe in hydrochloric acid solution 2+ When >160mg / L, replace the hydrochloric acid solution in the pickling tank. The specific pickling process of each tank is shown in Table 1.

[0077] Table 1

[0078]

1#

2#

3#

4#

Hydrochloric acid solution temperature

77℃

77℃

75℃

75℃

Concentration of hydrochloric acid solution (mass)

4.5%

7%

...

Embodiment 2

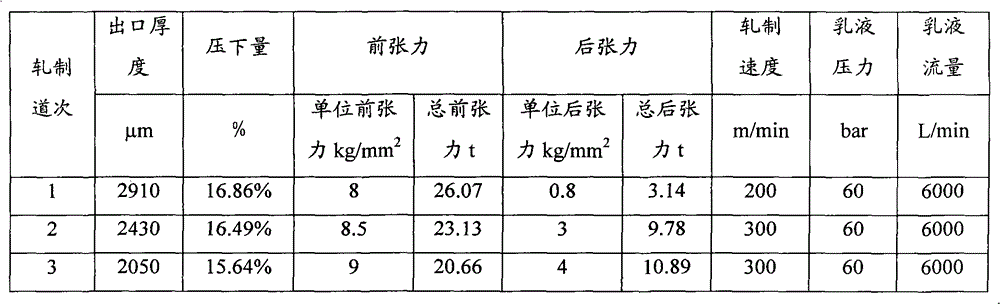

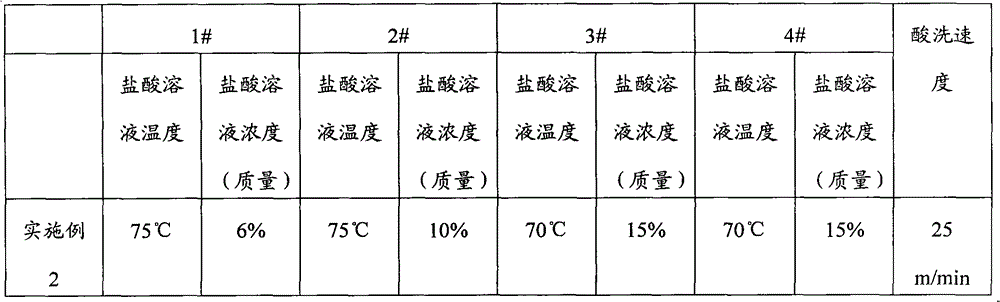

[0091] Example 2 adopts basically the same process conditions as in Example 1, and the changed parameters are shown in Table 3 pickling process parameters, Table 4 rolling process parameters, and Table 5 annealing process parameters.

[0092] table 3

[0093]

[0094] Table 4

[0095]

[0096] table 5

[0097]

[0098] The shape of the steel coil in this embodiment has no collapse, and the unevenness is ≤8mm / m. Except for the first circle of blue oxidation on the inside and outside of the steel coil, the others are free of oxidation (whole coil empty coil inspection). Using the sampling method of the national standard GB / T2975, the mechanical property testing method of GB / T228, and the equipment of GB / T16825, the following results are obtained:

[0099] The fifth circle of steel coil head ReL / Rm / A%=325 / 460 / 37,

[0100] Middle part of steel coil ReL / Rm / A%=345 / 480 / 33

[0101] ReL / Rm / A%=325 / 460 / 37 for the tenth circle at the end of the steel coil.

[0102] Full facto...

Embodiment 3

[0104] In this embodiment, the size of the hot-rolled coil billet is 2.9mm*1240mm, and the length is determined according to the needs. Yield strength 380MPa, tensile strength 500MPa, elongation 30%.

[0105] Example 3 adopts basically the same process conditions as in Example 1, and the changed parameters are shown in Table 6 Pickling Process Parameters, Table 7 Rolling Process Parameters, and Table 8 Annealing Process Parameters.

[0106] Table 6

[0107]

[0108] After the pickling treatment, the hot-rolled coil is trimmed, and the trimmed size is 2.9mm*1215mm.

[0109] Table 7

[0110]

[0111] Table 8

[0112]

[0113] Get the product specification (1.5±0.05mm)*1200. The shape of the steel coil in this embodiment has no collapse, and the unevenness is ≤8mm / m. Except for the first circle of blue oxidation on the inside and outside of the steel coil, the others are free of oxidation (whole coil empty coil inspection). Using the sampling method of the national...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com