Method for preparing high-quality stannic sulfide nanosheet by use of single-source molecular precursor

A tin sulfide, high-quality technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of many crystal defects, wide particle size distribution, and large product particle size, and achieve high crystallization degree and narrow particle size distribution , the effect of simple production equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

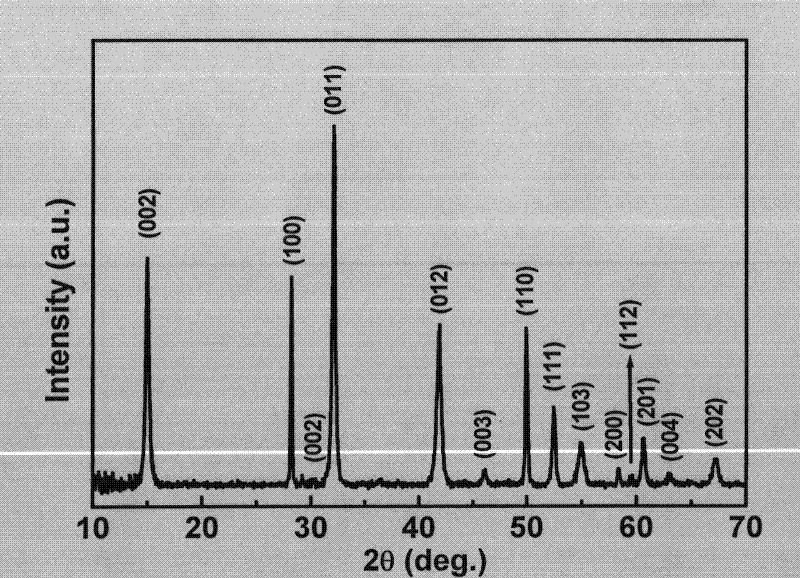

Embodiment 1

[0027] 1. Weigh 5 mmol of crystalline tin tetrachloride, dissolve in absolute ethanol, and prepare a 100 mL solution; 2. Weigh 20 mmol of sodium diethyldithiocarbamate powder, add anhydrous ethanol to dissolve, and prepare a 100 mL solution; 3 . The tin tetrachloride solution prepared in step (1) is slowly added to the sodium diethyldithiocarbamate solution prepared in step (2) at normal temperature and under stirring, and kept stirring for 1 hour at normal temperature, then the resulting precipitation is Suction filtration, and put it in an oven to dry at 60°C for 12 hours to obtain the precursor Sn-(DDTC) 4 ;4. Take 1.0g precursor Sn-(DDTC) 4 Put it into a 50mL polytetrafluoroethylene-lined autoclave, add 40mL of 2.5% acetic acid aqueous solution as a solvent, seal the autoclave and place it in an electric oven, heat it at 180°C for 24 hours, and then stop heating , let it cool to room temperature naturally, filter the obtained precipitate with suction, wash with deionized ...

Embodiment 2

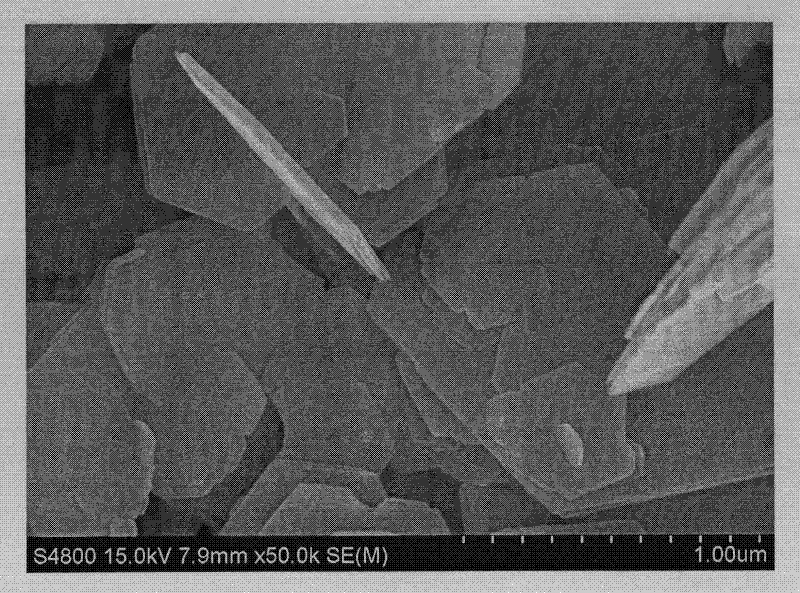

[0033] 1. Weigh 5 mmol of crystalline tin tetrachloride, dissolve in absolute ethanol, and prepare a 100 mL solution; 2. Weigh 20 mmol of sodium diethyldithiocarbamate powder, add anhydrous ethanol to dissolve, and prepare a 100 mL solution; 3 . The tin tetrachloride solution prepared in step (1) is slowly added to the sodium diethyldithiocarbamate solution prepared in step (2) at normal temperature and under stirring, and kept stirring for 1 hour at normal temperature, then the resulting precipitation is Suction filtration, and put it in an oven to dry at 60°C for 12 hours to obtain the precursor Sn-(DDTC) 4 ;4. Take 1.0g precursor Sn-(DDTC) 4 Put it into a 50mL polytetrafluoroethylene-lined autoclave, add 40mL of 5% acetic acid aqueous solution as a solvent, seal the autoclave, place it in an electric oven, heat it at 180°C for 24 hours, then stop heating and let It was naturally cooled to room temperature, the obtained precipitate was suction filtered, washed several times...

Embodiment 3

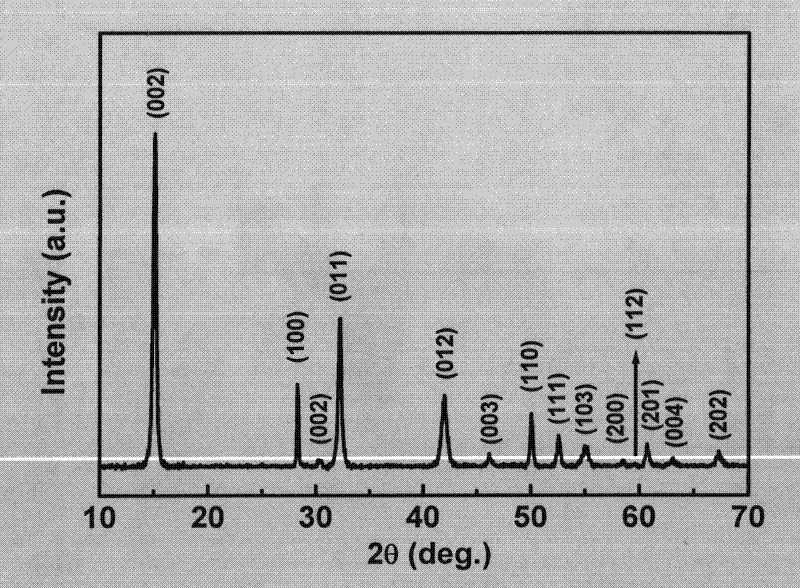

[0040] 1. Weigh 5mmol of crystalline tin tetrachloride, add absolute ethanol to dissolve, and make 100mL solution; 2. Weigh 20mmol sodium diethyldithiocarbamate powder, add absolute ethanol to dissolve, and make 100mL solution;

[0041] 3. The tin tetrachloride solution prepared in step (1) was slowly added to the sodium diethyldithiocarbamate solution prepared in step (2) at normal temperature and under stirring, and kept stirring for 1 hour at normal temperature, and then the obtained Precipitation and suction filtration, and put it in an oven to dry at 60 ° C for 12 hours to obtain the precursor Sn-(DDTC) 4 ;4. Take 1.0g precursor Sn-(DDTC) 4 Put it into a polytetrafluoroethylene-lined autoclave with a capacity of 50 mL, add 40 mL of 10% acetic acid aqueous solution as a solvent, seal the autoclave and place it in an electric oven, heat it at 180 ° C for 24 hours, then stop the heating, let It was naturally cooled to room temperature, the obtained precipitate was suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com