Optical element defect detection method based on machine vision technology

A defect detection and optical component technology, applied in the direction of optical testing of flaws/defects, material analysis by optical means, instruments, etc., can solve the problems of unstable micro-defect detection, etc., and achieve moderate price, powerful functions, and low false detection rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

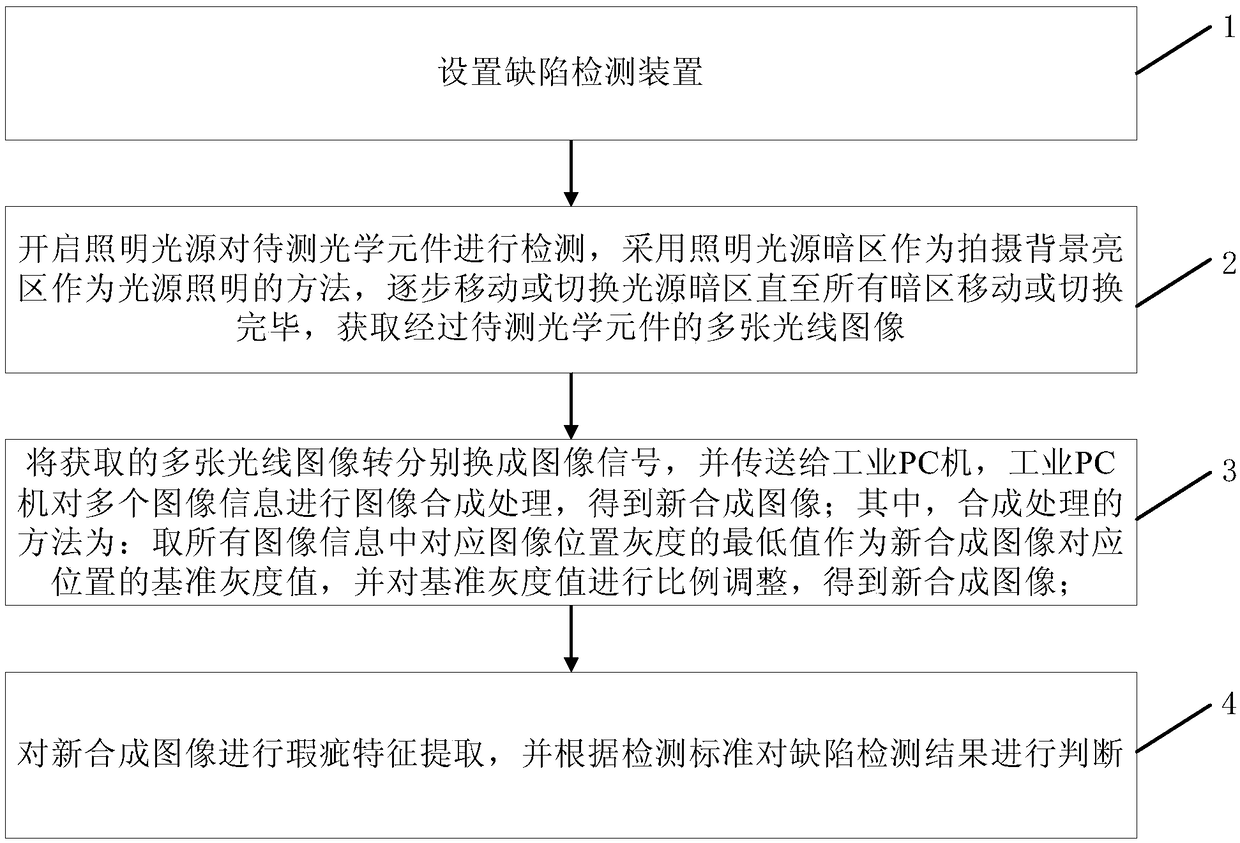

[0036] figure 2 It is a flow chart of the implementation of the optical element defect detection method based on machine vision technology of the present invention. This embodiment describes the detection of transmission defects, such as figure 2 As shown, the optical component defect detection method based on machine vision technology provided by the embodiment of the present invention includes:

[0037] Step 1, setting up a defect detection device.

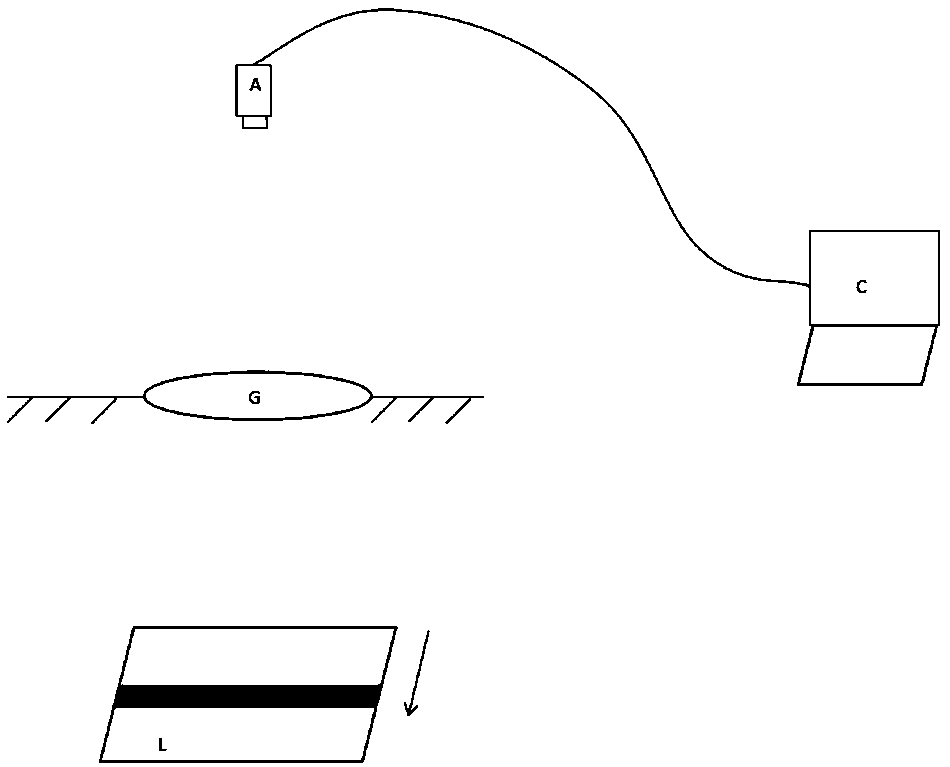

[0038] This embodiment is used for transmission-type defect detection. The illumination source and the image acquisition device are respectively located on both sides of the object to be tested. The image acquisition device can observe the image of the transmitted illumination source through the optical element under test.

[0039] The defect detection equipment in this embodiment includes: an illumination source, an image acquisition device, and an industrial PC. The image acquisition device observes the image of the transm...

Embodiment 2

[0068] This embodiment is basically consistent with Embodiment 1, the difference is:

[0069] This embodiment is used to detect reflective defects, such as Figure 9 As shown, in step 1, the defect detection device is set up, the illumination source and the image acquisition device are respectively located on the same side of the object to be tested, and the light source is reflected to the image acquisition device through the object to be tested, and the image acquisition device can observe through the optical element under test to the image of the reflected illumination source. What is obtained in step 2 is the reflected ray image.

[0070] At the same time, in order to improve the speed of detection, the lighting source can be used such as Figure 4 As shown, that is, the black and white checkerboard replaces the transformation method instead of the horizontal or vertical dark field stripe scanning method. In this method, the industrial camera only needs to collect two im...

Embodiment 3

[0072] This embodiment is basically consistent with Embodiment 1, the difference is:

[0073] This embodiment is used to detect optical elements with special shapes, such as optical elements with a certain R value, such as Figure 10 As shown, the dark-field lighting source is located at the focal length of the object under test, and the industrial camera only needs to collect one image to analyze the defects of the object under test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com