Automatic detection device of electrical connectors

An electrical connector and automatic detection technology, which is applied in the field of electrical connector automatic detection equipment, can solve the problems of company increase, large labor cost, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

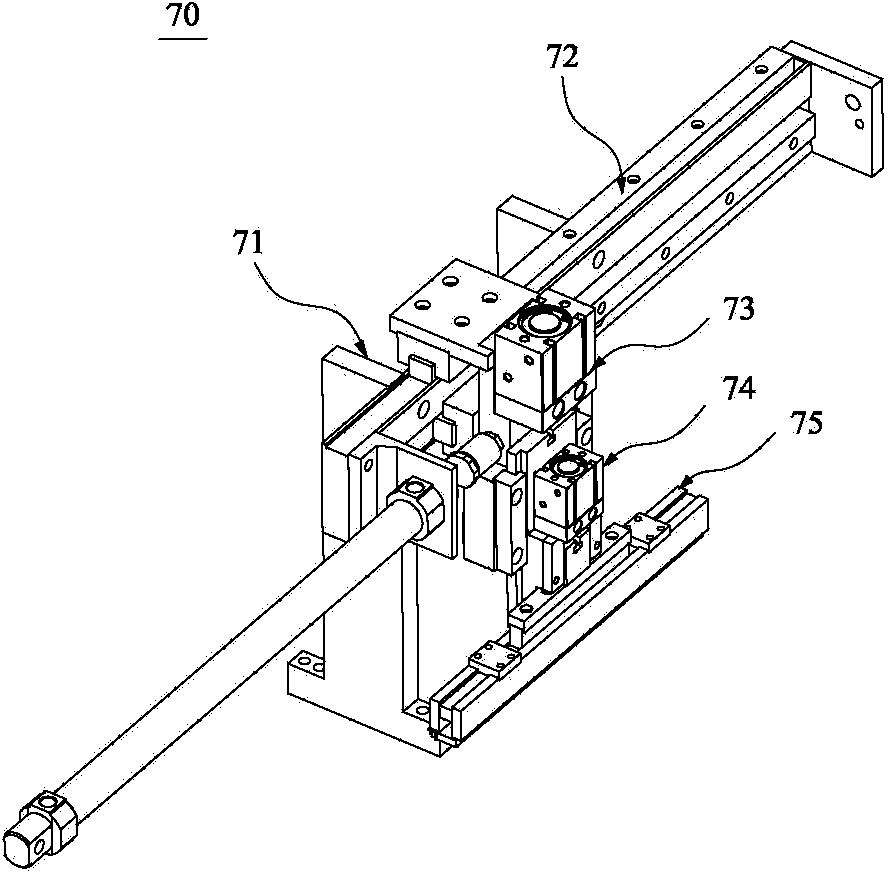

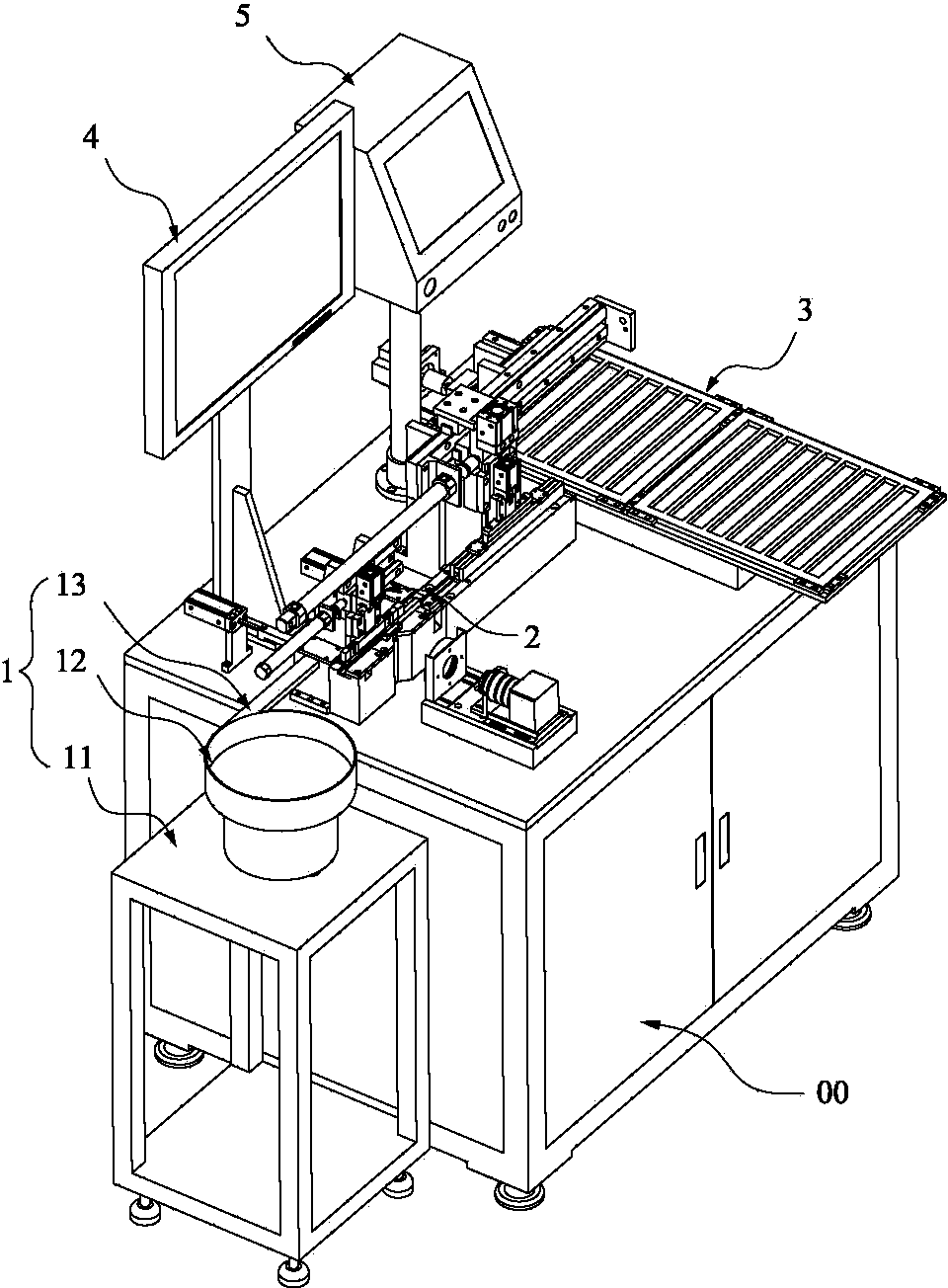

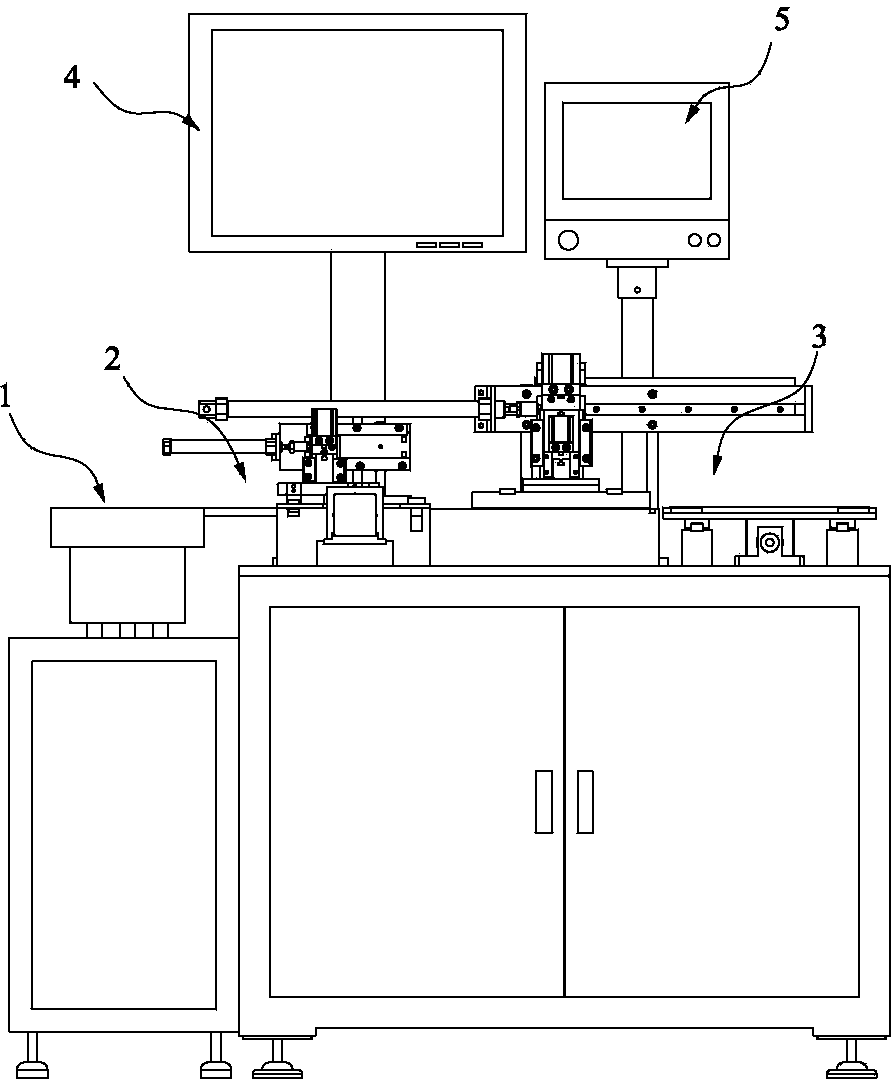

[0087] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, including three parts 1, 2, 3 for shaking materials, detection and packaging, and the shaking materials, detection and packaging parts 1, 2, 3 are arranged in sequence, First, the shaker part 1 arranges the electrical connectors neatly to the feeding channel, and the detection part 2 sends the electrical connectors to the set detection station through the driving device, and uses the CCD image recognition technology to detect the position of each terminal in the electrical connector socket. The flatness is tested, qualified products are sent to the packaging part 3 for overall packaging, and unqualified products are automatically picked out, thereby realizing the automatic operation of the testing and packaging lines, effectively improving efficiency and reducing labor costs.

[0088] It should be pointed out that the product detected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com