Self-supporting thin polymer film

A polymer film, self-supporting technology, applied in membranes, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of low density, wide size distribution, practical use limitations, etc., to achieve the effect of large surface area and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Block copolymers were synthesized as follows.

[0124] Liquid crystalline methacrylate monomer MA(Stb) was synthesized as follows.

[0125] 4-Butylbenzoic acid (manufactured by Tokyo Chemical Industry Co., Ltd., special grade) was reduced with boron trifluoride diethyl ether complex and sodium borohydride to obtain 4-butylbenzyl alcohol. Using the Williamson method, 4-hydroxybenzaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd., special grade) and 11-bromo-1-undecanol (manufactured by Wako Pure Chemical Industries, Ltd., special grade) were condensed to obtain 4-(11- hydroxyundecyloxy)benzaldehyde. The resulting 4-butylbenzyl alcohol was brominated with hydrogen bromide, and then reacted with triphenylphosphine (manufactured by Wako Pure Chemical Industries, Ltd., special grade) to obtain (4-butylbenzyl)triphenylphosphine. Phenyl bromide obtained by making The salt reacts with potassium tert-butoxide to form salt (ylide), and then add 4-(11-hydroxyunde...

Embodiment 2

[0132] A 1% by weight solution of cellulose acetate (Mw. 30000) in acetone was spin-coated on a silicon wafer at a speed of 3000 rpm for 60 seconds to form a sacrificial layer. The film was heated at 60° C. for about 1 hour in the air to remove acetone remaining in the film. Next, a 4% by weight chloroform solution of the copolymer produced in Example 1 was spin-coated on the sacrificial layer at a speed of 2000 rpm for 30 seconds, and heat treatment (annealing treatment) was performed at 190° C. for 2 hours under vacuum, thereby A microphase-separated structure membrane is obtained.

Embodiment 3

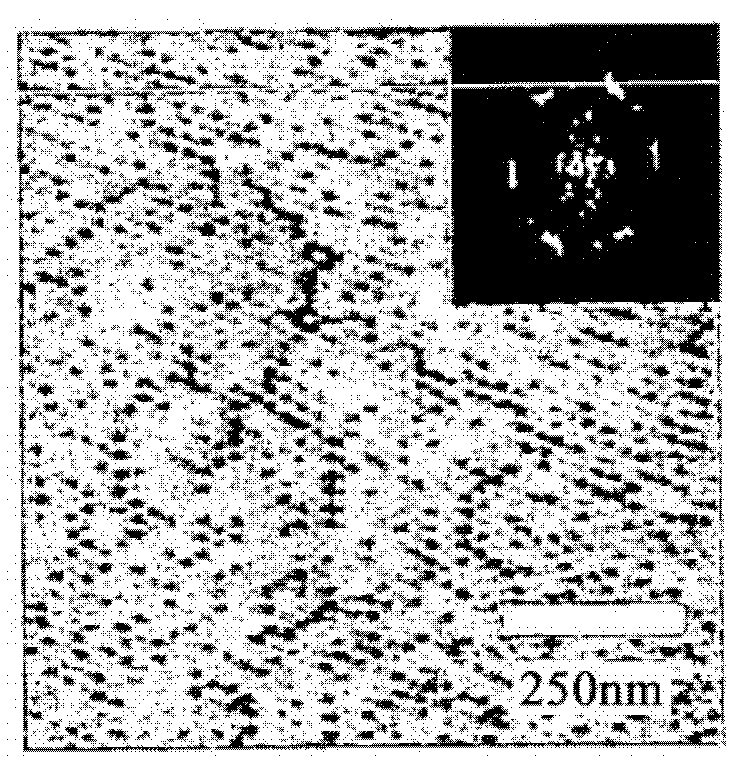

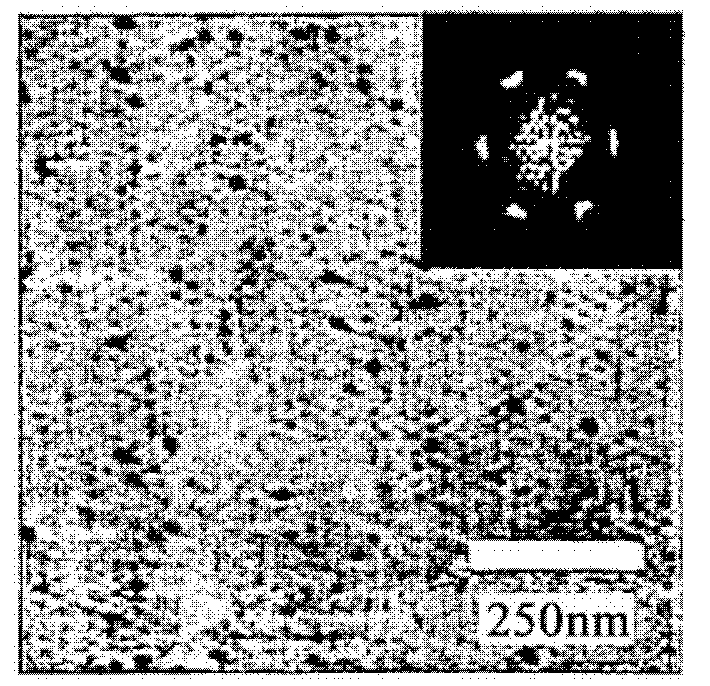

[0134] Regarding the microphase-separated structure of the polymer thin film obtained in Example 2, the surface structure was observed using an atomic force microscope (AFM). Photographs representing AFM results as figure 1 shown. Depend on figure 1 It was found that on the surface of the polymer film obtained in Example 2, a hexagonal dot pattern derived from polyethylene oxide blocks (hydrophilic polymer components) was observed.

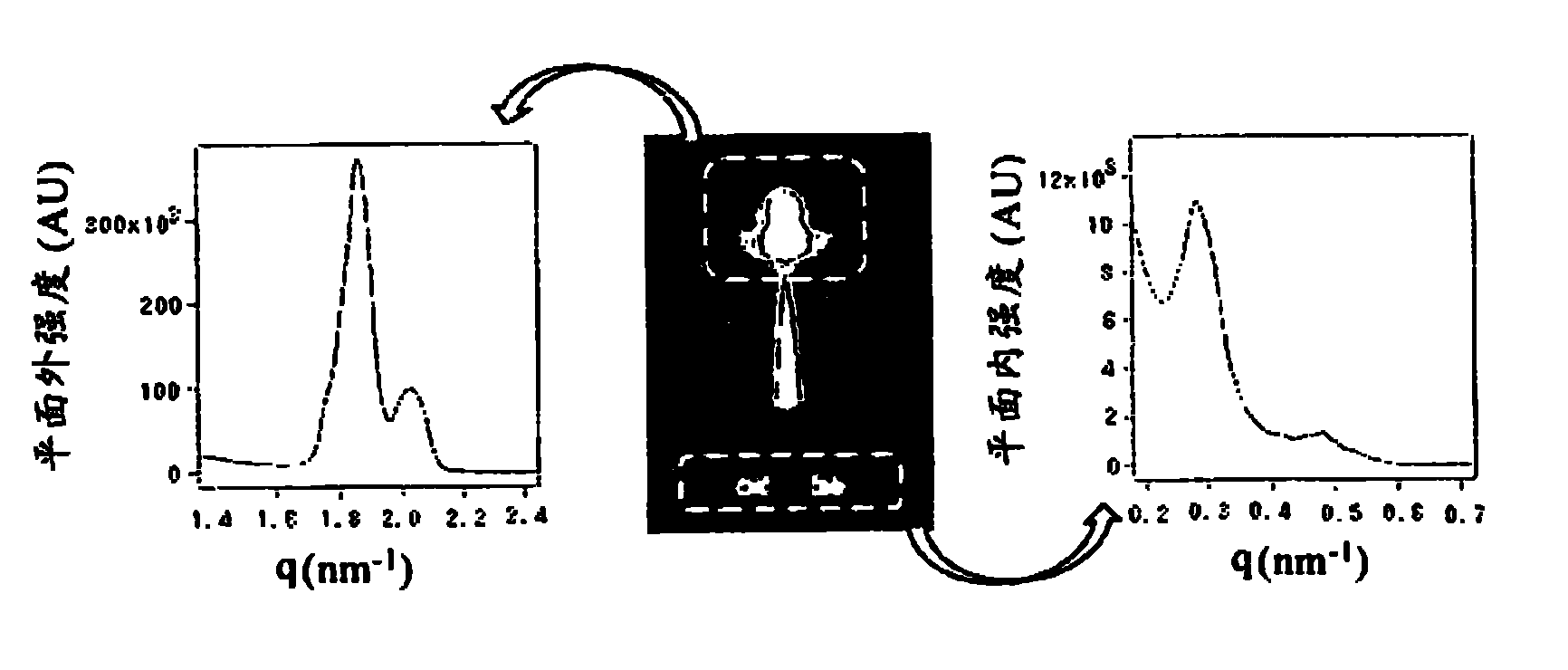

[0135] Next, the structural periodicity of the polymer film obtained in Example 2 was measured by grazing incidence small-angle X-ray scattering (GI-SAXS). The result is as figure 2 shown. Depend on figure 2 It can be seen that the polyethylene oxide block (hydrophilic polymer component) pillars in the polymer film obtained in Example 2 form a hexagonal arrangement. From the results of AFM and GI-SAXS, it can be confirmed that the polymer film obtained in Example 2 also formed a microphase-separated structure on the polyacetic acid cellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com