Smelting method of lead concentrate containing antimony and zinc

A smelting method and concentrate technology, which is applied in the field of smelting complex lead concentrates containing antimony and zinc, can solve the problems of inability to recover valuable metals at one time, low labor productivity, and difficulty in flue gas treatment, and achieve large production capacity and adaptable materials The effect of strong resistance and high SO2 concentration in flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

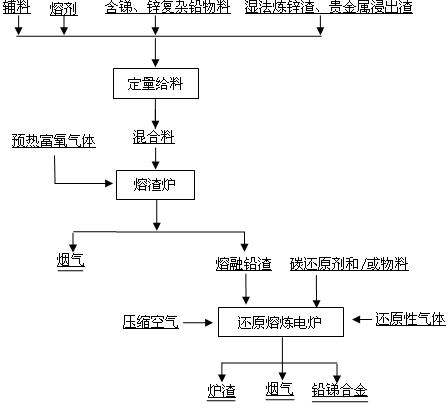

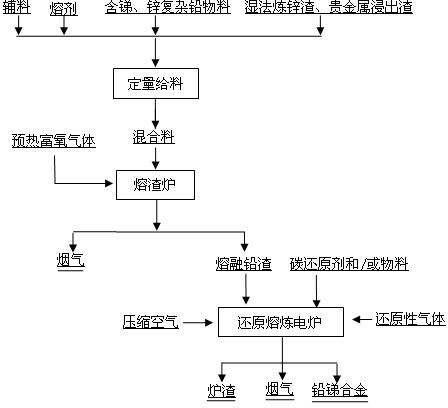

Method used

Image

Examples

Embodiment 1

[0061] The treatment consists of a mixture containing 40% Pb, 15% Sb, 6% Zn, 25% S, and 2500 g / t Ag, with a water content of ~8.5%, and the particle size 2 Mass ratio is 1.3 and CaO:SiO 2 The mass ratio is 0.8, and it is fed through the slag furnace (1) feeding port (2), and at the same time, preheated air with a temperature of 550℃ is sprayed from the slag furnace (1) injection port (3) to perform self-heating full oxidation smelting , Keep the slag temperature at ~1050℃. It produces metal oxide slag with a temperature of ~1050℃ and SO2 flue gas containing S ~ 15%. The SO2-containing flue gas is discharged through the flue (4) of the reduction smelting electric furnace, and is used for waste heat. After dust collection, it is sent to the acid system. The smoke dust is received as the oxide soot containing 20% lead and 60% antimony, and it is directly refined by removing lead and antimony.

[0062] The temperature produced by the slag furnace (1) is ~1050°C. The metal oxid...

Embodiment 2

[0064] The processing consists of a mixture containing 30% Pb, 25% Sb, 4% Zn, 19% S, and 3000g / t Ag. The water content is ~9.5%. 2 The mass ratio is 1.4 and CaO:SiO 2 The mass ratio is 0.7, and 5% of the crushed coke is mixed into it through the slag furnace (1) feeding port (2), and at the same time, the injection temperature of the slag furnace (1) (3) is 100 ℃, oxygen It is 30% preheated oxygen-rich gas for self-heating full oxidation smelting to maintain the slag temperature at ~1000°C. Produces metal oxide slag with a temperature of ~1000℃ and SO containing S ~ 10% 2 Smoke. Contains SO 2 The flue gas is discharged through the flue (4) of the reduction smelting electric furnace, is used for waste heat, and is sent to the acid system after dust collection and dust removal. The soot that is received is oxide soot containing lead to 16% and antimony to 65%, which is directly removed for refining.

[0065] The temperature produced by the slag furnace (1) is ~1000°C. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com