High-performance aluminum/carbon composite electrode foil and preparation method thereof

A technology of carbon composite and electrode foil, which is applied in the direction of capacitor electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of poor compatibility, insufficient conductivity and stability, etc., to overcome poor compatibility, The effect of increasing the surface area and improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

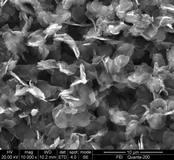

Image

Examples

Embodiment 1

[0032] Example 1 1 part by weight of polyvinylidene fluoride, 98.5 parts by weight of graphite powder with an average particle size of 25 microns, and 0.5 part by weight of a silane coupling agent are uniformly dispersed in a solvent (N-methylpyrrolidone) to obtain a slurry with a solid content of 5%. The slurry is coated on both sides of a corroded aluminum foil with a thickness of 50 μm by dipping, and the thickness of one side of the carbon layer is 50 μm after drying. Put the pole piece at N 2 The atmosphere was maintained at 350°C for 48h.

Embodiment 2

[0033] Example 2 6 parts by weight of polytetrafluoroethylene emulsion (aqueous emulsion with 50% polytetrafluoroethylene content), 96 parts by weight of graphite powder with an average particle diameter of 15 microns, and 1 part by weight of titanate coupling agent in a solvent (dimethyl carbonate ) to obtain a slurry with a solid content of 10%. The slurry was coated on both sides of a corroded aluminum foil with a thickness of 50 μm by dipping. After drying, the thickness of one side of the carbon layer was 35 μm. Put the pole piece at N 2 The atmosphere was maintained at 380°C for 40h.

Embodiment 3

[0034] Example 3 5 parts by weight of epoxy resin, 94.5 parts by weight of graphite with an average particle size of 20 microns, and 0.5 parts by weight of titanate coupling agent were uniformly mixed and dispersed in a solvent (propylene glycol methyl ether) to obtain a slurry with a solid content of 20%. The slurry was coated on both sides of a corroded aluminum foil with a thickness of 50 μm by a knife coating method, and the thickness of one side of the carbon layer was 45 μm after drying. Put the pole piece at N 2 The atmosphere was maintained at 400°C for 36h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com