Manufacturing method for back contact type silicon solar cell

A silicon solar cell and back contact technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve problems affecting the mechanical strength of devices, complex manufacturing processes, and broken silicon wafers, so as to improve photoelectric conversion efficiency and simplify the manufacturing process. , the effect of reducing the fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

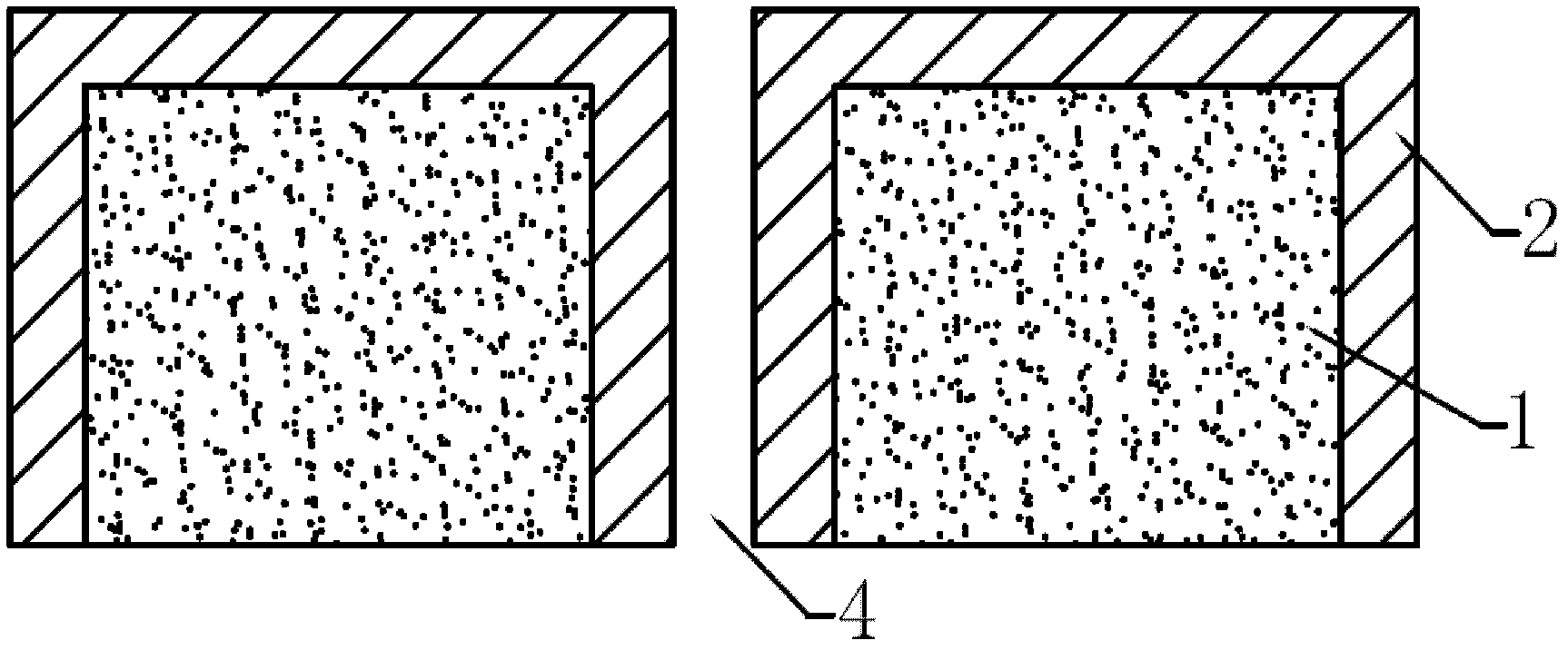

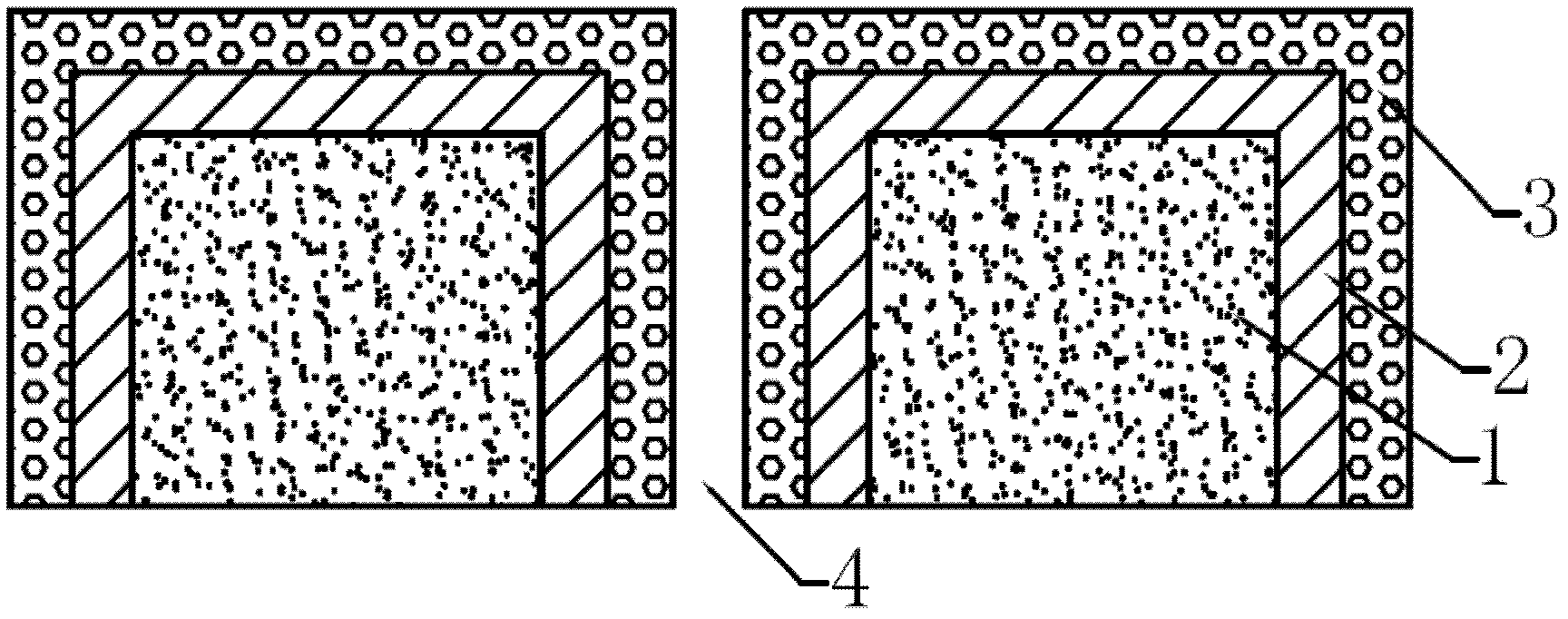

[0039] see figure 1 Shown in ~9, a kind of preparation method of back contact silicon solar cell, silicon chip is n-type, comprises the following steps:

[0040](1) Holes 4 are opened on the surface of the silicon wafer, the number of which is 60. Its function is to set electrodes in the holes to lead the current from the light-receiving surface of the battery to the backlight surface of the battery, so that the positive and negative electrodes of the battery can be They are all located on the back of the battery sheet; in this embodiment, laser, mechanical drilling or chemical etching can be used to open holes; The uneven structure is formed on the surface to extend the propagation path of light on the surface, thereby improving the absorption of light by the silicon wafer; the schematic diagram of the silicon wafer structure after opening is as follows figure 1 shown;

[0041] (2) Boron diffusion is carried out on the surface of the silicon wafer, and the PN junction 2 i...

Embodiment 2

[0051] A method for preparing a back-contact silicon solar cell, the silicon wafer is p-type, comprising the steps of:

[0052] The first step is to open holes on the silicon wafer, the number of which is 100. Its function is to set electrodes in the through holes to lead the current from the light-receiving side of the battery to the backlight of the battery, so that the positive electrode and the backlight of the battery can be connected to each other. The negative electrodes are all located on the back of the battery sheet; in this embodiment, laser, mechanical drilling or chemical etching can be used to open holes;

[0053] The second step is texturing; its purpose is to form a rough structure on the surface of the original bright silicon wafer through chemical reaction to prolong the propagation path of light on its surface, thereby improving the absorption of light by the silicon wafer;

[0054] The third step is to diffuse phosphorus on the surface of the silicon wafer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com