Microwave scanning detection method of polyethylene pipeline electric smelting joint

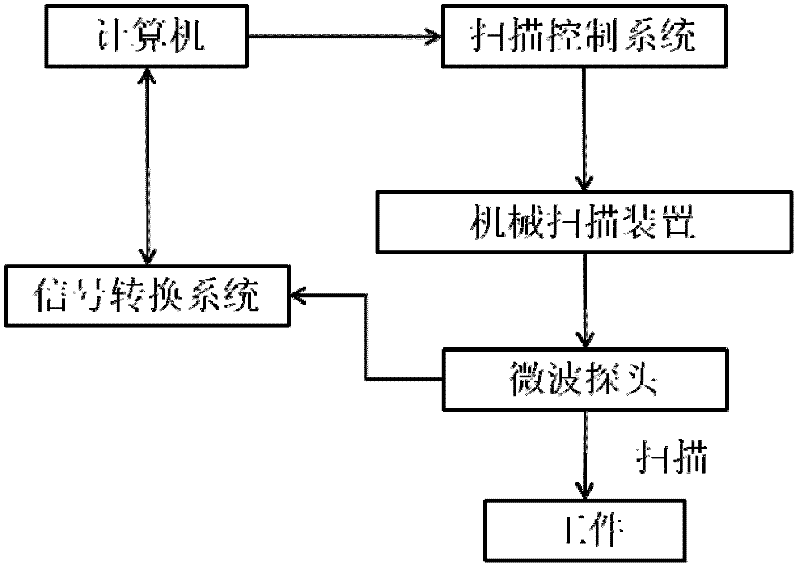

An electrofusion joint, scanning detection technology, applied in the direction of using microwave flaw detection, can solve the problems of difficult detection, lack of reliability, impact on joint quality and performance, and achieve the effect of avoiding material contamination and rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

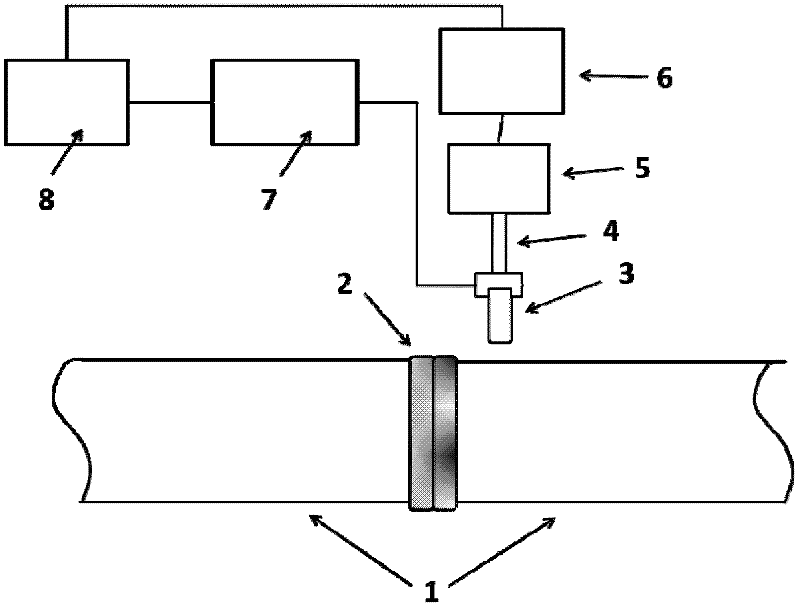

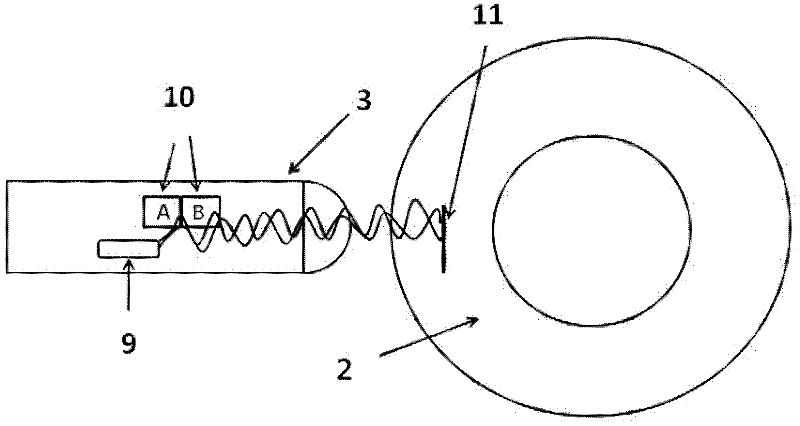

Embodiment 1

[0046] The microwave detection device provided by the invention is used to detect a complete and non-defective polyethylene pipe electrofusion joint. First, the outer surface of the joint is simply treated to make it smooth and flat, and then the joint is detected according to the steps in the technical solution provided by the present invention. The microwave frequency used is 24 GHz, and the scanning speed is 20 cm / s. The distance between the outer surface of the joint and the joint is controlled at 2cm; in this embodiment, the signals recorded by the receiving sensors A and B are respectively displayed through the baseline amplitude, and the obtained microwave scanning images are shown in Figure 4 . In the figure, the X coordinate represents the axial direction, and the Y coordinate represents the radial direction. The HAZ of the EF joint was about 0.25 inches wide with a centerline at about Y=2. The scanning image of the electrofusion joint is relatively uniform in the ...

Embodiment 2

[0048] The microwave detection device provided by the invention is used to detect a polyethylene pipe electrofusion joint containing cold welding defects. First, the outer surface of the joint is simply treated to make it smooth and flat, and then the joint is detected according to the steps in the technical solution provided by the present invention. The microwave frequency used is 24 GHz, and the scanning speed is 10 cm / s. The distance between the outer surface of the joint and the joint is controlled at 3cm; in this embodiment, the signals recorded by the receiving sensors A and B are respectively displayed through the baseline amplitude. When the traveling microwave encounters a defect, the change in the dielectric constant makes the microwave A reflection occurs. The reflected microwave signal and the emitted microwave signal form an interference pattern, and the obtained microwave scanning image is shown in Figure 5 . Taking Example 1 as a reference example, the high ...

Embodiment 3

[0050] A polyethylene pipe electrofusion joint containing crack defects is detected by using the microwave detection device provided by the invention. First, simple treatment is performed on the outer surface of the joint to make it smooth, and then the joint is detected according to the steps in the technical solution provided by the present invention. The microwave frequency used is 24 GHz, and a uniform scanning speed is adopted. The scanning speed is 15 cm / s, and the microwave probe The distance between the outer surface of the joint and the joint is controlled at 4cm; in this embodiment, the signals recorded by the receiving sensors A and B are respectively displayed through the baseline amplitude. When the traveling microwave encounters a defect, the change in the dielectric constant makes the microwave A reflection occurs. The reflected microwave signal and the emitted microwave signal form an interference pattern, and the obtained microwave scanning image is shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com