Genetic engineering bacterium for producing succinic acid and method for producing succinic acid by fermentation of genetic engineering bacteria

A technology of genetically engineering bacteria and producing succinic acid, applied in the field of bioengineering, can solve problems such as wasting resources and polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

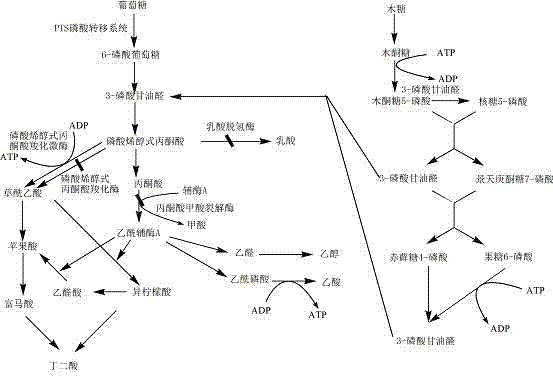

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example illustrates the use of homologous recombination technology to knock out phosphoenolpyruvate carboxylase in the starting strain NZN111 ppc gene, resulting in the elimination of apramycin-resistant strains.

[0042] 1. Using LB medium, cultivate Escherichia coli NZN111 to OD at 37°C under aerobic conditions 600 =0.4~0.6, prepared to be electrotransfer competent.

[0043] 2. Electrotransform plasmid pKD46 into competent Escherichia coli NZN111. The electric shock conditions were: 200 Ω, 25 μF, electric shock voltage 2.3 kV, electric shock time 4-5 ms. Immediately after the electric shock, the cells were added to pre-cooled 1 mL SOC medium, cultured at 150 r / min, 30°C for 1 h, and then spread on the LB medium plate with ampicillin (amp) to screen the positive transformant Escherichia coli NZN111 ( pKD46).

[0044] 3. Add 10 mM L-arabinose to LB medium, induce plasmid pKD46 to express λ recombinase at 30°C, and make electroporation competent.

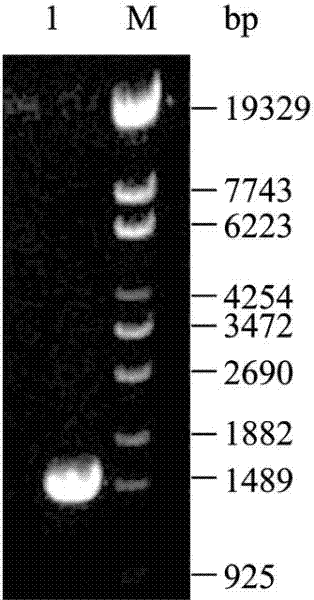

[0045] 4. U...

Embodiment 2

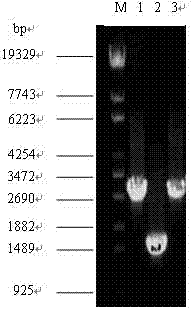

[0056] This example illustrates the method of constructing an expression plasmid that overexpresses phosphoenolpyruvate carboxykinase, can efficiently utilize xylose for fermentation, and accumulate a large amount of succinic acid to obtain the strain Escherichia coli BA204.

[0057] 1. Construction of an expression plasmid for overexpressing phosphoenolpyruvate carboxykinase, the process comprising:

[0058] (1) synthetic with Sac I and Xba Primers for I restriction sites,

[0059] Upstream primer: 5'- CGAGCTCATGAACTCAGTTGATTTGACCG -3';

[0060] Downstream primer: 5'-GCTCTAGAGCATTCCGTCAATTAAAACAAG -3'.

[0061] (2) with Bacillus subtilis The genome was used as a template, and the target gene fragment was amplified by PCR. The reaction conditions were: 94°C for 5 min; (94°C for 45 s, 53°C for 45 s, 72°C for 100 s, 35 cycles); 72°C for 10 min. purified amplified pck After the gene, the expression plasmid was used respectively with pTrc99a Sac I and Xba I double d...

Embodiment 3

[0065] This example illustrates the comparison between Escherichia coli BA204 and the starting strain to produce acid by fermentation.

[0066] Escherichia coli BA204 can efficiently utilize xylose for fermentation, and accumulate succinic acid in large quantities. It adopts a two-stage fermentation method. Aerobic culture bacteria OD 600 Induce to OD at about 0.4-0.6 with 0.3 mM IPTG 600 =3, transfer to serum bottle for anaerobic fermentation according to 10% inoculum size, and ferment for 48 h.

[0067] The aerobic phase medium is: LB+Amp (ampicillin 50 μg / mL).

[0068] The medium in the anaerobic stage was: LB+xylose (20 g / L)+basic magnesium carbonate 0.48 g+Amp (ampicillin 50 μg / mL)+0.3 mM IPTG.

[0069] The fermentation results are shown in Table 1.

[0070] Table 1 Escherichia coli Comparison of BA204 and starting strains for acid production

[0071]

[0072] Note: ND means not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com