A method for improving the efficiency of aspergillus producing organic acids

An organic acid and Aspergillus technology, applied in the field of bioengineering, can solve problems such as patent publications that have not yet been found, and achieve the effects of improving biosynthesis ability, shortening fermentation cycle, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation of described aspergillus seed liquid is as follows:

[0049] 2~4% glucose, 0.01~0.02% metal ions, 1~2% nitrogen source, sterilized at 115°C for 30 min, inoculated with Aspergillus spores 1.5×10 6 cells / mL, incubate at 30°C and 200 rpm for 14-20 h;

[0050] Wherein, the above percentage is the final mass concentration.

[0051] Preferably, the volume ratio of the waste cordyceps fermentation broth and fermentation medium is 1-3:5.

[0052] Preferably, the discarded cordyceps fermented liquid is one or more mixed liquids of cordyceps militaris fermented liquid, Xinjiang cordyceps fermented liquid, and Liangshan cordyceps fermented liquid.

[0053]Preferably, the volume ratio of the waste cordyceps fermentation liquid and the fermentation medium is: 1-3:5, wherein the waste cordyceps fermentation liquid is a single species of cordyceps fermentation liquid or a mixed liquid of two or more cordyceps fermentation liquids;

[0054] Or, when adding two kinds ...

Embodiment 1

[0069] Example 1 Method for improving the efficiency of malic acid production by Aspergillus by exogenously adding waste cordyceps fermentation broth

[0070] The operation steps of multiple experimental groups are basically the same, and the difference is only that the type and consumption of the waste cordyceps fermentation broth are different. For details, see Table 1:

[0071]

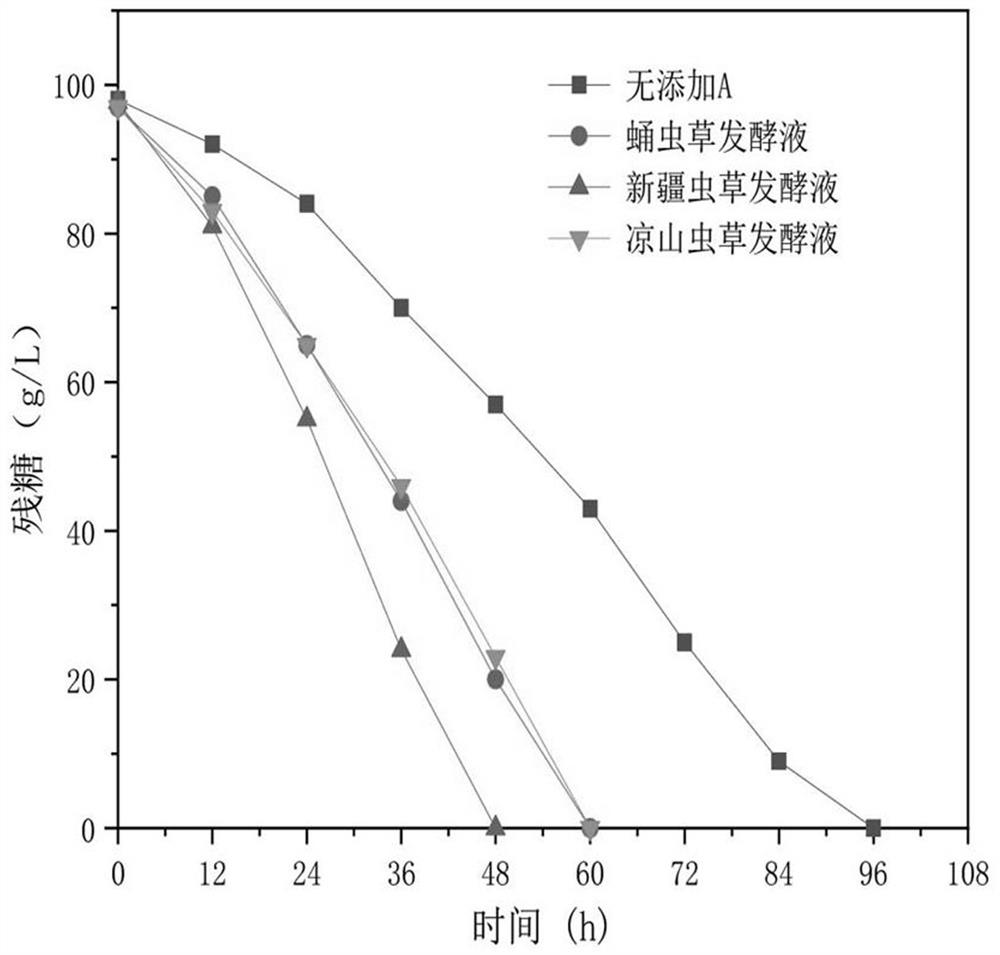

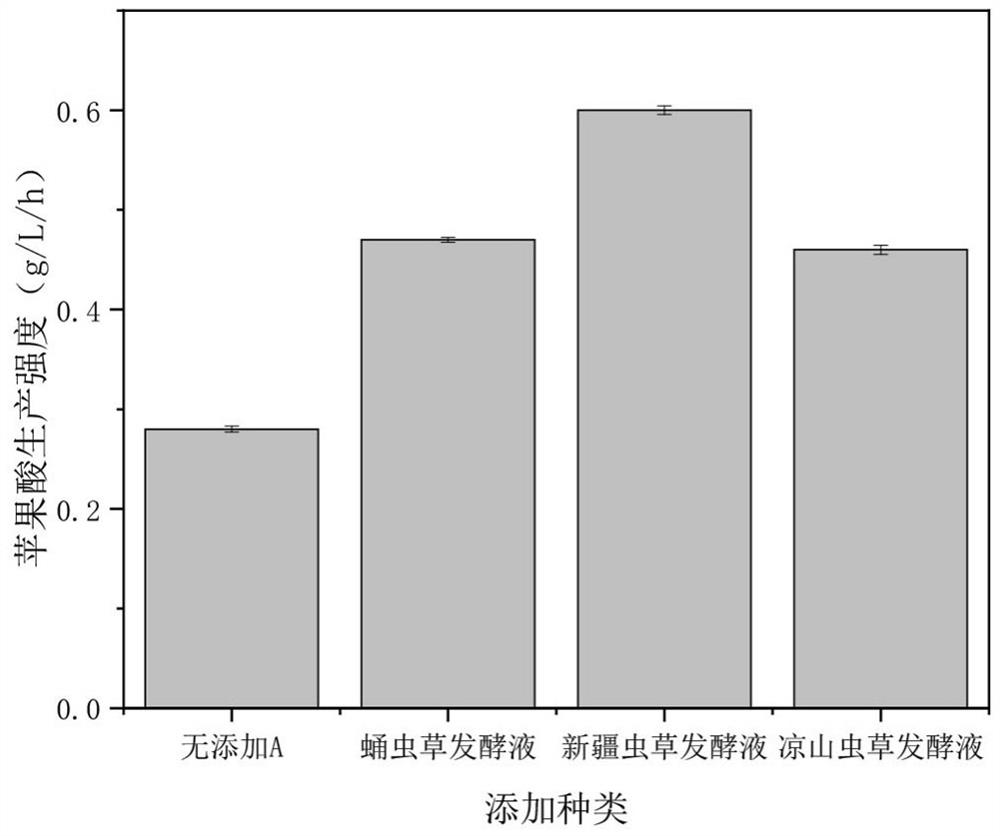

[0072] The fermentation time (the time from residual sugar to single digits) in experimental groups 1-3 was recorded, the changes in glucose content during fermentation were detected, and the organic acid production efficiency was calculated.

[0073] No-addition group A: This group is the control group of experimental groups 1-3. The same method as the experimental group is used to ferment and produce organic acids, except that the fermentation medium does not add waste cordyceps fermented liquid.

[0074] The organic acid production efficiency of experimental groups 1-3 and control group A was...

Embodiment 2

[0078] Example 2 The method for improving the efficiency of citric acid production by Aspergillus by adding waste cordyceps fermentation broth

[0079] The operation steps of multiple experimental groups are basically the same, and the difference is only that the type and consumption of waste cordyceps fermentation broth are different. For details, see Table 2:

[0080]

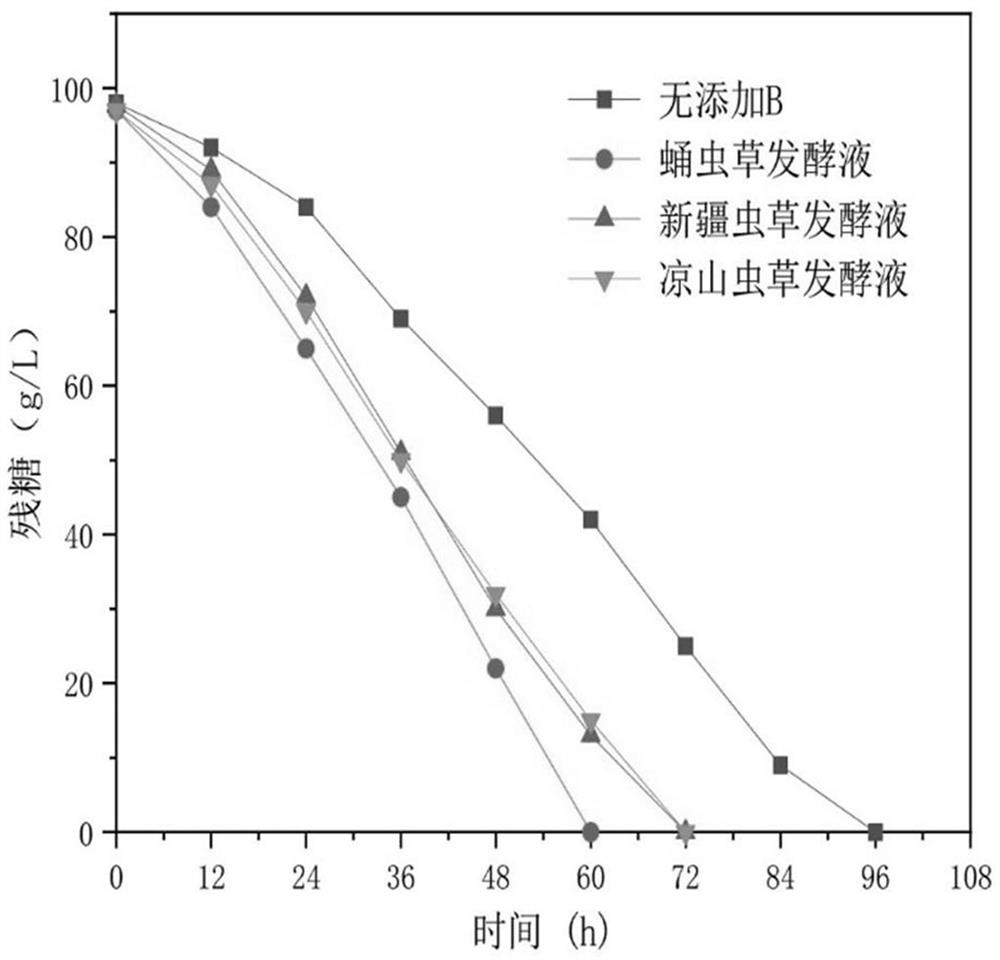

[0081] Record the time of fermentation and cultivation in specific experimental groups 4-6 (the time from the amount of residual sugar to single digit), detect the change of glucose content during fermentation and cultivation, and calculate the production efficiency of organic acid.

[0082] No-addition group B: This group is the control group of experimental groups 4-6. The same method as the experimental group is used to ferment and produce organic acids, except that the fermentation medium does not add waste cordyceps fermented liquid.

[0083] The organic acid production efficiency of experimental grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com