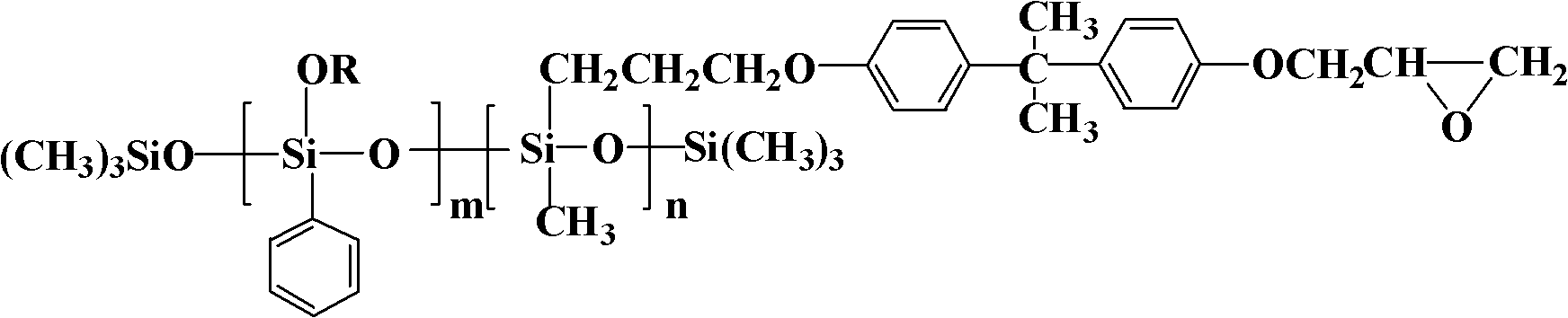

Polysiloxane low polymer with side epoxy group and preparation method thereof

A kind of technology of phenyltrialkoxysilane and polysiloxane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

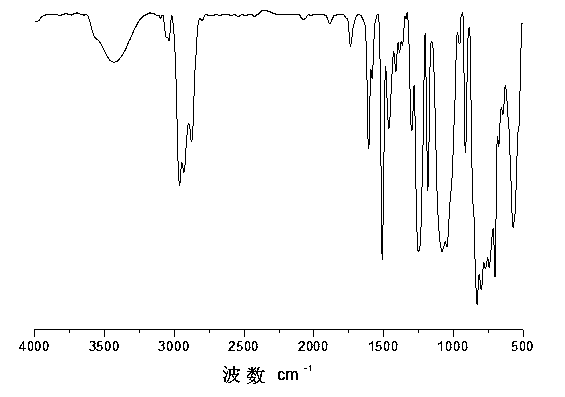

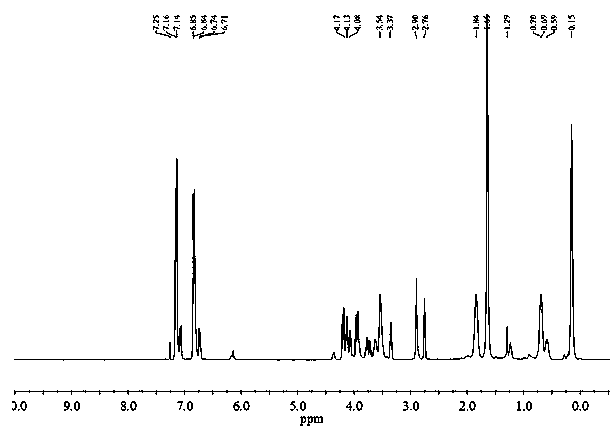

Image

Examples

Embodiment 1

[0024] Step 1. Add 0.08mol γ-chloropropylmethyldimethoxysilane, 0.1mol phenyltriethoxysilane, 116g Toluene, heat the reaction system to 85°C, add 17.5g of dilute hydrochloric acid with a mass fraction of 7% dropwise, after reacting for 5 hours, add 0.0108mol trimethylchlorosilane, continue the reaction for 3 hours, remove the water layer after cooling, and wash with saturated sodium sulfate Wash the toluene layer with an aqueous solution to neutrality to obtain a polychloropropylphenylsiloxane toluene solution, which is completely transferred to a 250ml four-neck flask equipped with a stirrer, a reflux condenser, a thermometer, and a dropping funnel;

[0025] Step 2, in another 250ml four-necked flask equipped with stirrer, reflux condenser, thermometer, feed N 2 , add 0.07mol bisphenol A, 0.14mol sodium hydroxide and 90g deionized water, heat up to 90°C, reflux reaction for 1.5h under stirring, and obtain bisphenol A sodium salt solution after cooling; the prepared bisphenol ...

Embodiment 2

[0031]Step 1. Add 0.02mol γ-chloropropylmethyldiethoxysilane, 0.1mol phenyltrimethoxysilane, and 96g toluene to a 250ml four-neck flask equipped with a stirrer, reflux condenser, thermometer, and dropping funnel , heat the reaction system to 85°C, add 14.4g of dilute hydrochloric acid with a mass fraction of 5% dropwise, and react for 8 hours, add 0.012mol hexamethyldisiloxane, continue the reaction for 3 hours, remove the water layer after cooling, and wash with saturated sulfuric acid Wash the toluene layer with sodium aqueous solution to neutrality to obtain a polychloropropylphenylsiloxane toluene solution, which is all transferred to a 250ml four-necked flask equipped with a stirrer, a reflux condenser, a thermometer, and a dropping funnel;

[0032] Step 2, in another 250ml four-necked flask equipped with stirrer, reflux condenser, thermometer, feed N 2 , add 0.02mol bisphenol A, 0.06mol potassium hydroxide and 81g deionized water, heat up to 80°C, reflux reaction for 1h ...

Embodiment 3

[0037] Step 1. Add 0.05mol γ-chloropropylmethyldiethoxysilane, 0.1mol phenyltrimethoxysilane, and 91g toluene to a 250ml four-neck flask equipped with a stirrer, reflux condenser, thermometer, and dropping funnel , heat the reaction system to 90°C, add 12.1 g of dilute hydrochloric acid with a mass fraction of 7% dropwise, and after reacting for 6 hours, add 0.003 mol of hexamethyldisiloxane, continue the reaction for 4 hours, remove the water layer after cooling, and wash with saturated sulfuric acid Wash the toluene layer with sodium aqueous solution to neutrality to obtain a polychloropropylphenylsiloxane toluene solution, which is all transferred to a 250ml four-necked flask equipped with a stirrer, a reflux condenser, a thermometer, and a dropping funnel;

[0038] Step 2, in another four-necked flask equipped with stirrer, reflux condenser, thermometer, add and feed N 2 , 0.05mol bisphenol A, 0.1mol sodium hydroxide and 108g deionized water, heated up to 100°C, reflux rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com