Low-odor non-toxic non-benzene environment-friendly composite plasticizer

A compound plasticizer and low-odor technology, which is applied in the direction of fat production, fat oil/fat refining, etc., to achieve the effect of high addition amount, low odor, and enhanced application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Epoxidized soybean oil winterization treatment

[0041] The epoxidized soybean oil was cooled to 9°C with a winterization rate of 3°C / h in the early stage, 0.2°C / h in the late stage, and 6°C in the later stage. The crystal growth time was 15h, and the stirring speed was 3rpm. After filtration and separation, the winterized epoxidized soybean oil was obtained, and the epoxy value of the winterized epoxidized soybean oil was tested to be 6.6%.

[0042] The winterization rate of epoxy hog oil methyl ester is 4°C / h in the early stage, and the temperature is lowered to 9°C, and the winterization rate in the later stage is 0.5°C / h, and the temperature is dropped to 6°C, the crystal growth time is 10h, and the stirring speed is 5rpm. After filtration and separation, the winterized epoxy hog oil methyl ester was obtained, and the epoxy value of the winterized epoxy hog oil methyl ester was tested to be 5.6%.

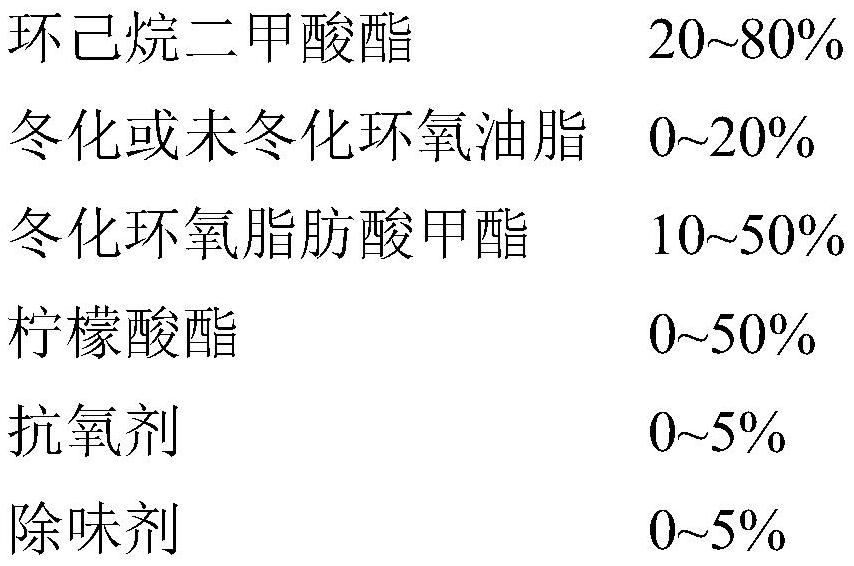

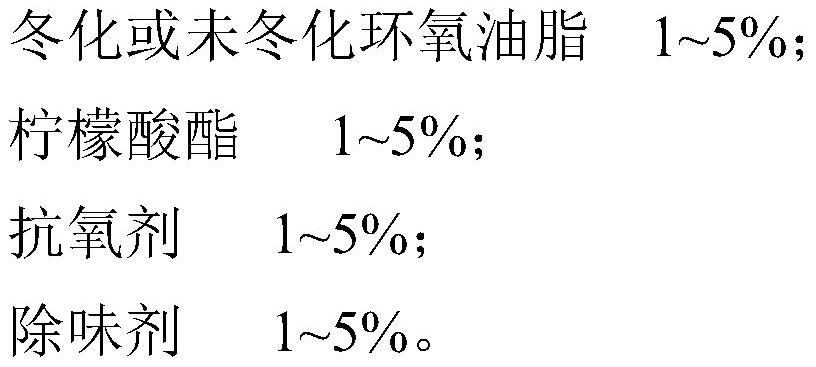

[0043] 2) Preparation of composite plasticizer

[0044] Diisono...

Embodiment 2

[0046] 1) Winterization treatment of epoxy palm oil and epoxy palm oil methyl ester.

[0047] Epoxy palm oil is passed through the early winterization rate of 3 ℃ / h, cooled to 9 ℃, the late winterization rate of 0.2 ℃ / h, cooled to 6 ℃, crystal growth time 15h, stirring speed 3rpm. After filtration and separation, the winterized epoxy palm oil was obtained, and the epoxy value of the winterized epoxy palm oil was tested to be 6.1%.

[0048] Epoxy palm oil methyl ester is passed through the early winterization rate of 4 ℃ / h, cooling to 9 ℃, the late winterization rate of 0.5 ℃ / h, cooling to 6 ℃, crystal growth time 10h, stirring speed 5rpm. After filtration and separation, the winterized epoxy palm oil methyl ester was obtained, and the epoxy value of the winterized epoxy palm oil methyl ester was tested to be 5.0%.

[0049] 2) Preparation of composite plasticizer

[0050] Diisononyl 1,2-cyclohexanedicarboxylate (67% by weight), winterized epoxy palm oil (2% by weight), ...

Embodiment 3

[0052] 1) Winterization treatment of epoxy hog oil methyl ester.

[0053] The winterization rate of epoxy hog oil methyl ester is 6°C / h in the early stage, and the temperature is lowered to 9°C. The winterization rate in the later stage is 0.5°C / h, and the temperature is dropped to 6°C. The crystal growth time is 10h, and the stirring speed is 5rpm. After filtration and separation, the winterized epoxy hog oil methyl ester was obtained, and the epoxy value of the winterized epoxy hog oil methyl ester was tested to be 5.8%.

[0054] 2) Preparation of composite plasticizer

[0055] Diisononyl 1,2-cyclohexanedicarboxylate (62% by weight), epoxidized soybean oil (2% by weight) (epoxy value 6.2%), winterized epoxy hog oil methyl ester (30 % by weight), acetyl tributyl citrate (3% by weight), phosphite (3% by weight), calcium ricinoleate (2% by weight) and zinc ricinoleate (1% by weight). Put it into a stainless steel stirring tank according to the proportion, control the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com