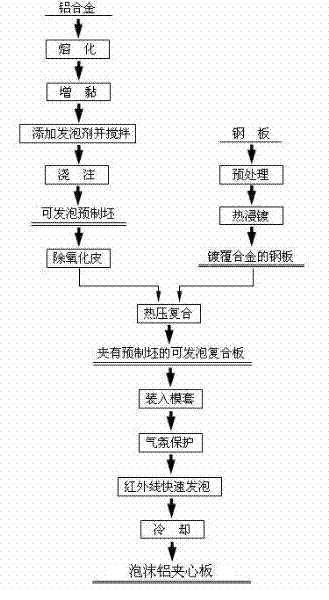

Preparation method of foamed aluminum sandwich plate

A sandwich panel and foamed aluminum technology, which is applied in the field of layered composite material preparation, can solve the problems of difficult control of the thickness of the foamed aluminum sandwich panel and the structure of the core layer, complex production equipment, and high production cost, achieving rapid preparation and short cooling time , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take Al-12wt.% Si as the aluminum alloy matrix, melt it at 750°C and keep it warm for 30 minutes, add the tackifier metal Ca and stir evenly. The amount of Ca added is 5wt.% of the aluminum alloy used, and the particle size is 6mm. Stir The speed is 1500r / min, and the stirring time is 2min. Reduce the temperature of the aluminum alloy melt after viscosification to 600 °C, and add TiH to it 2 and stir well. Stirring speed is 1000r / min, stirring time is 5min, TiH 2 The particle size is 150μm, and the amount added is 0.5wt.% of the mass of the matrix alloy used. Before adding, TiH 2 Oxidation treatment was carried out at 500° C. for 5 hours in air. Casting the obtained aluminum melt into an ingot and rolling it in a hot state to obtain a foamable preform with a thickness of 5mm, the porosity of the foamable preform is 20%;

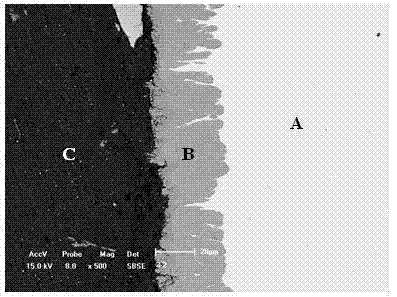

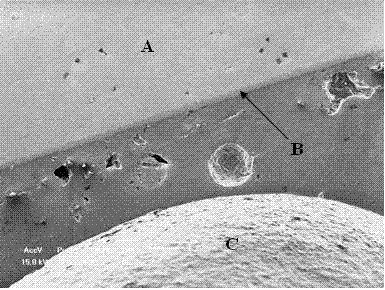

[0036] Degrease and derust the surface of the steel plate with a thickness of 1mm to expose the clean substrate surface, and then coat the surface...

Embodiment 2

[0039] Example 2 is the same as in Example 1, except that the amount of Ca added is 2wt.% of the quality of the aluminum alloy used, the stirring speed is 500r / min, and the stirring time is 5min; TiH 2 The amount of addition is 3wt.% of the mass of the matrix alloy used, the stirring speed is 3000r / min, the stirring time is 2min, TiH 2 The particle size is 30 μm, before adding the TiH 2 Oxidation treatment was carried out at 500° C. for 1 hour in air.

Embodiment 3

[0041] Use Al-12wt.%Si-1wt.%Mg as the aluminum alloy matrix, melt it at 750°C and keep it warm for 30min, add SiC particles and stir evenly, the amount of SiC added is 2wt.% of the quality of the aluminum alloy used, and the particle size is 10μm , the stirring speed is 1500r / min, and the stirring time is 2min. Reduce the temperature of the aluminum alloy melt after viscosification to 590 °C, and add TiH to it 2 and stir well. Stirring speed is 2000 r / min, stirring time is 3min, TiH 2 The particle size is 80μm, and the amount added is 1.5wt.% of the mass of the matrix alloy used. Before adding, TiH 2 Oxidation treatment at 500°C for 3 hours. The obtained aluminum melt is cast into an ingot and rolled in a hot state to obtain a foamable preform with a thickness of 10mm, and the porosity of the foamable preform is 17%;

[0042] Degrease and derust the surface of the steel plate with a thickness of 1mm to expose the clean substrate surface, and then coat the surface of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com