Catalyst ingredient for olefin polymerization and preparation method thereof

An olefin polymerization and catalyst technology, applied in the field of catalyst components and catalysts, can solve the problems of complex forming steps, difficult to control, high material prices, etc., and achieve high catalytic activity, good hydrogen adjustment sensitivity, and excellent comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take 30ml of hexane, 3.15ml of dibutylmagnesium hexane solution (1M) and 1.0ml of isooctyl alcohol in turn, raise the temperature to 50°C and keep stirring for half an hour to obtain a transparent solution, then add styrene butadiene triblock Copolymer (Kraton, FG1901X, polybutadiene content 70%) hexane solution (10g / L) 1ml, cool to -10 ℃, add 0.36ml silicon tetrachloride and 0.35ml titanium tetrachloride successively, add After feeding, the temperature was rapidly raised to 50° C. within 10 minutes, and the reaction was maintained for 2 hours. The temperature of the catalyst suspension was lowered to room temperature, allowed to stand, settled, washed three times with hexane, each time the amount of hexane was 50 milliliters, and after the washing was completed, it was dried to obtain a brown solid fluid powder with an average particle size of 56.2 microns.

[0039] Elemental analysis (ICP): Ti: 9.48% by weight, Mg: 20.84% by weight.

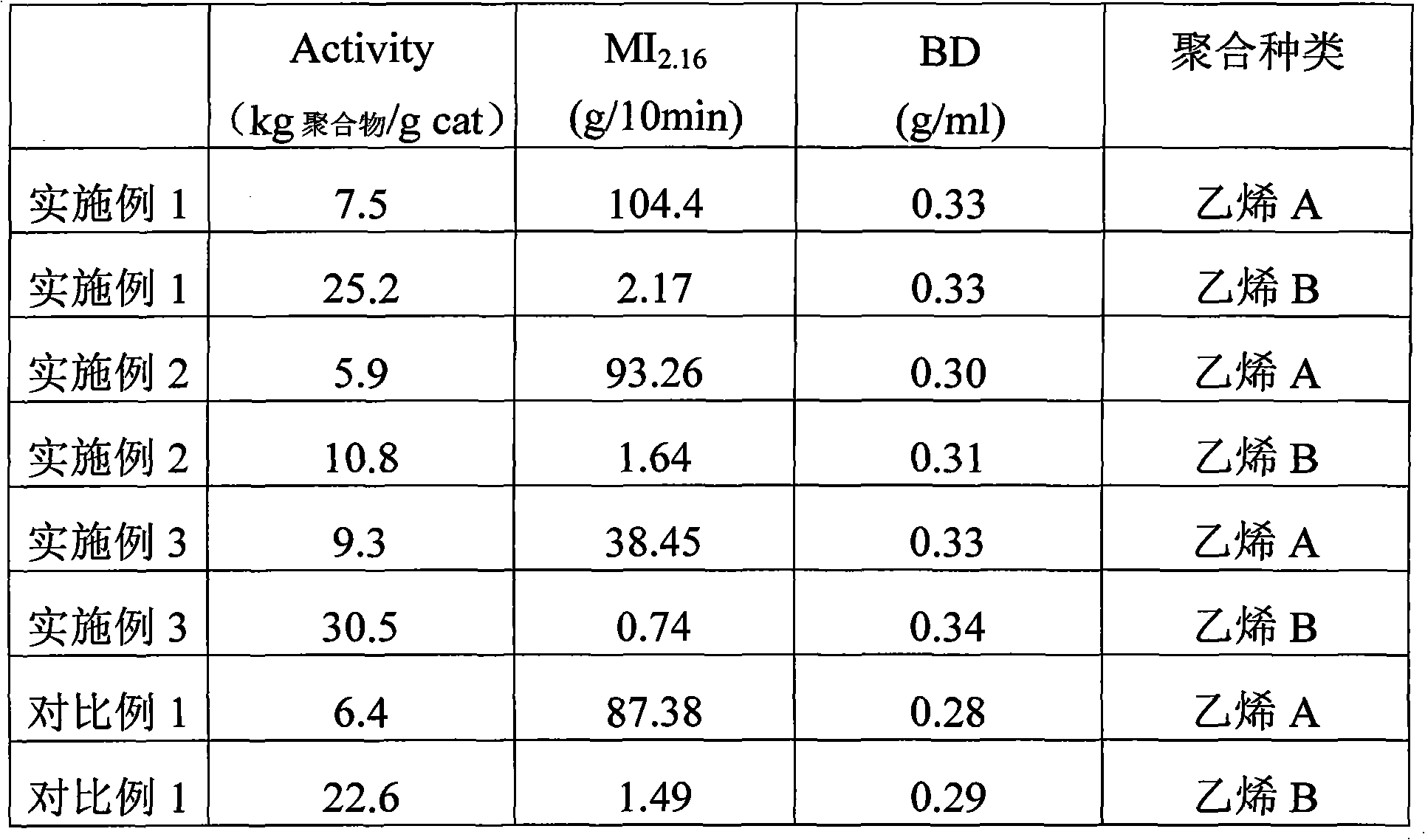

[0040] Ethylene polymerization...

Embodiment 2

[0043] In the catalyst preparation process, the temperature was rapidly raised to 50° C. within 10 minutes, and changed to 70° C. within 10 minutes. The other conditions were the same as in Example 1, and the average particle size was 85.2 microns.

[0044] Elemental analysis (ICP): Ti: 5.12% by weight, Mg: 12.81% by weight.

[0045] The ethylene slurry polymerization evaluation conditions of the catalyst are the same as in Example 1, and the polymerization results are shown in Table 1.

Embodiment 3

[0047] Change the 1.0ml isooctyl alcohol in the catalyst preparation process into 0.6ml n-butanol, change the 1ml of hexane solution (10g / L) that adds styrene-butadiene triblock copolymer into 3ml, and change it into 3ml within 10 minutes. Rapidly raise the temperature to 50°C, then change the temperature to naturally and slowly rise to room temperature, and then heat to 50°C. Other conditions are the same as in Example 1, and the average particle size is 24.3 microns.

[0048] Elemental analysis (ICP): Ti: 11.66% by weight, Mg: 24.39% by weight.

[0049] The ethylene slurry polymerization evaluation conditions of the catalyst are the same as in Example 1, and the polymerization results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com