Lithium ion gel electrolyte based on polymethyl methacrylate-polystyrene diblock copolymer, and preparation method thereof

A technology of polymethyl methacrylate and gel electrolyte, which is applied in circuits, electrical components, secondary batteries, etc., can solve the problems of electrolyte leakage, explosion, battery expansion and deformation, etc., and achieve good film-forming properties and high ionic strength conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

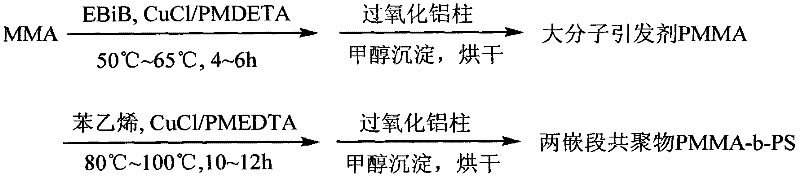

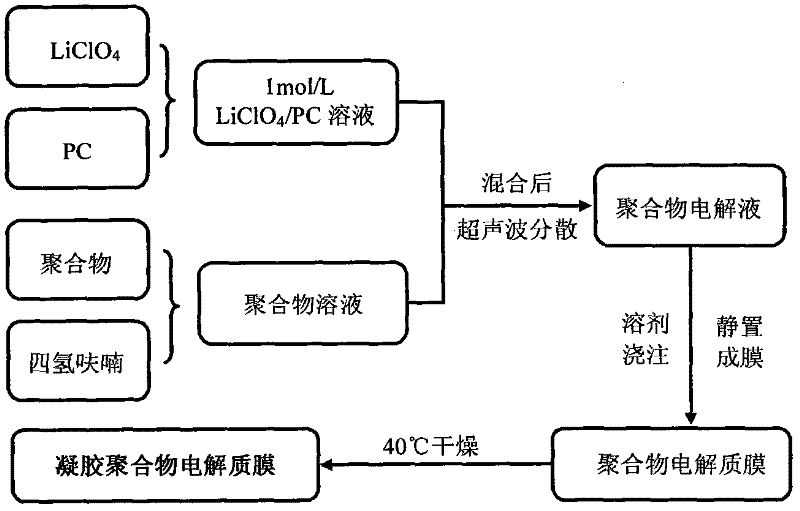

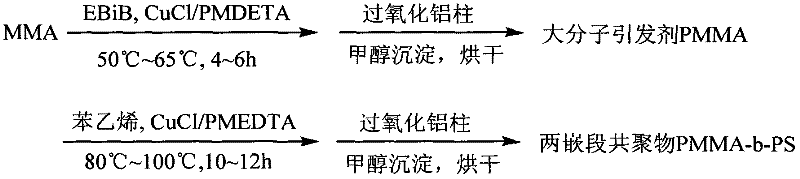

[0022] Step 1: Preparation of polymethyl methacrylate macroinitiator. Methyl methacrylate (MMA), initiator 2-bromoethyl isobutyrate (EBiB), catalyst cuprous chloride (CuCl) / pentamethyl divinyl triamine (PMDETA), the molar ratio of the four substances is 50:1:2:1~150:1:2:1, mixed and placed in a three-necked flask, using tetrahydrofuran as solvent for solution polymerization, nitrogen protection, reaction temperature 50-65°C, reaction time 4-6h. After the reaction, the solution was passed through a neutral alumina column to remove copper ions, and then precipitated with methanol to obtain a white solid, which was dried in a vacuum drying oven at 40°C to a constant weight, which is a macromolecule of polymethyl methacrylate (PMMA) Initiator, the number average molecular weight measured by gel permeation chromatography (GPC) is 1.578×10 4 , The molecular weight distribution is 1.12.

[0023] Step 2: Preparation of the diblock copolymer polymethyl methacrylate-polystyrene. Styrene,...

Embodiment 2

[0025] Example 2: The second example of PMMA-b-1PS-based gel electrolyte:

[0026] Step 1 and Step 2 are the same as Example 1, except that the diblock copolymer PMMA-b-1PS added in Step 3 is 0.40g; the lithium salt plasticizer solution added is 0.6g, and the polymer mass fraction It is 40wt%.

Embodiment 3

[0027] Example 3: The third example of PMMA-b-1PS-based gel electrolyte:

[0028] Step 1 and Step 2 are the same as Example 1, except that the diblock copolymer PMMA-b-1PS added in Step 3 is 0.45g; the lithium salt plasticizer solution added is 0.55g, and the polymer mass fraction is It is 45wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com