Magnetic submicron composite core-shell particles, and preparation method and application thereof

A composite particle and sub-micron technology, which is applied in the fields of magnetic properties of inorganic materials, chemical instruments and methods, and alkali metal compounds, can solve the problems of secondary pollution, high cost, and low adsorption efficiency, and achieve stable adsorption performance and good adsorption efficiency , to avoid the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

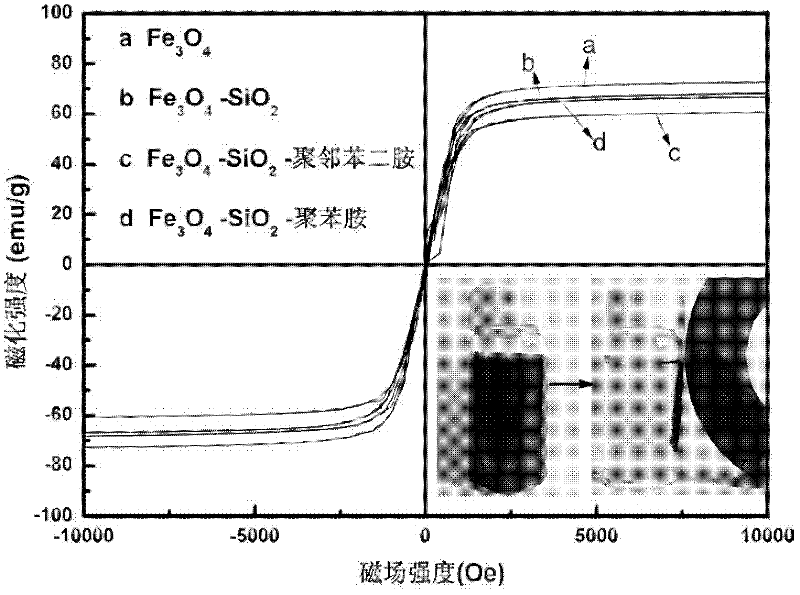

[0052] (1) Prepare Fe according to the general procedure 3 o 4 submicron particles

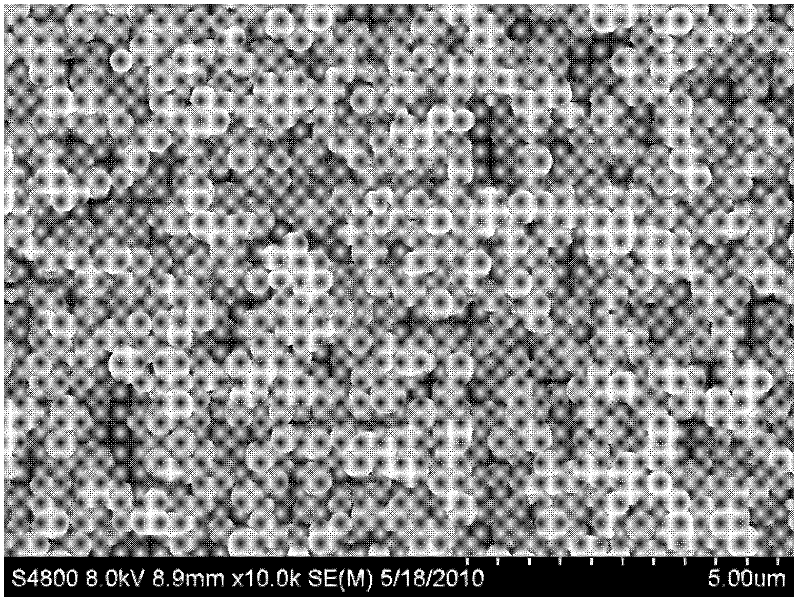

[0053]Dissolve 1.35 g of ferric trichloride hexahydrate in 40 mL of ethylene glycol, add 3.6 g of sodium acetate, and 1.0 g of polyethylene glycol 400 (molecular weight: 400) to form a mixed solution. The mixed solution was stirred for 30 min, sealed in a 100 mL autoclave, and reacted at 200° C. for 8 h. The obtained product was magnetically separated by a magnet, washed 3-5 times with deionized water, and dried in vacuum at 60°C for 6 hours to obtain a black magnetic Fe 3 o 4 Submicron particle powder, the particle size is 300nm-600nm.

[0054] (2) Prepare Fe according to the general procedure 3 o 4 -SiO 2 Composite particles

[0055] The prepared above-mentioned Fe 3 o 4 Pour 1.0g of submicron particles into a three-necked flask, add 100g of isopropanol, stir at 40°C for 30min, then add 5.5g of deionized water, 0.66g of ammonia water with a concentration of 30% by mass and 0.3g of ...

Embodiment 2

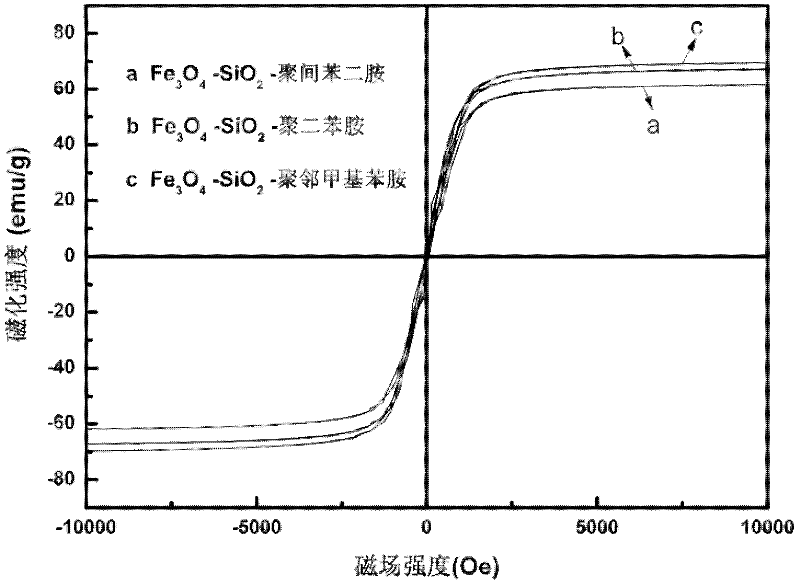

[0057] The magnetic Fe prepared by 0.5g embodiment 1 3 o 4 -SiO 2 Submicron composite particles were added to 50 g of chloroform, and 0.1 g of thiophene monomer was added, and stirred thoroughly for 30 min to make them uniformly dispersed. 0.25g anhydrous FeCl 3 (ferric iron ion as an initiator) was uniformly dissolved in 10 g of chloroform, added dropwise to the above mixed solution, and reacted at 20° C. for 4 h. The reaction product was magnetically separated, washed with water and ethanol for 3 times, and then dried in vacuum at 60°C for 6 hours to obtain 400nm dense (Fe 3 o 4 -SiO 2 - polythiophene) magnetic submicron composite core-shell particles.

Embodiment 3

[0059] The magnetic Fe prepared by 1g embodiment 1 3 o 4 -SiO 2 Submicron composite particles were added to 900g of chloroform, and 2g of diaminothiophene monomer was added, and stirred thoroughly for 30min to make them evenly dispersed. 5 g anhydrous FeCl 3 Uniformly dissolved in 100g of chloroform (ferric iron ion as initiator), added dropwise to the above mixed solution, and reacted at 20°C for 4h. The reaction product was magnetically separated, washed with water and ethanol for 5 times, and dried in vacuum at 60°C for 12 hours to obtain 1000nm dense (Fe 3 o 4 -SiO 2 - polydiaminothiophene) magnetic submicron composite core-shell particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com