Antistatic flame-retardant acrylonitrile butadiene styrene (ABS) rubber material and preparation method thereof

An ABS resin and antistatic technology, applied in the field of preparation of antistatic materials, can solve the problems of difficult control of material resistivity, poor processing performance of composite materials, and reduction of mechanical properties of materials, etc., to achieve good mechanical processing performance, good processability, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

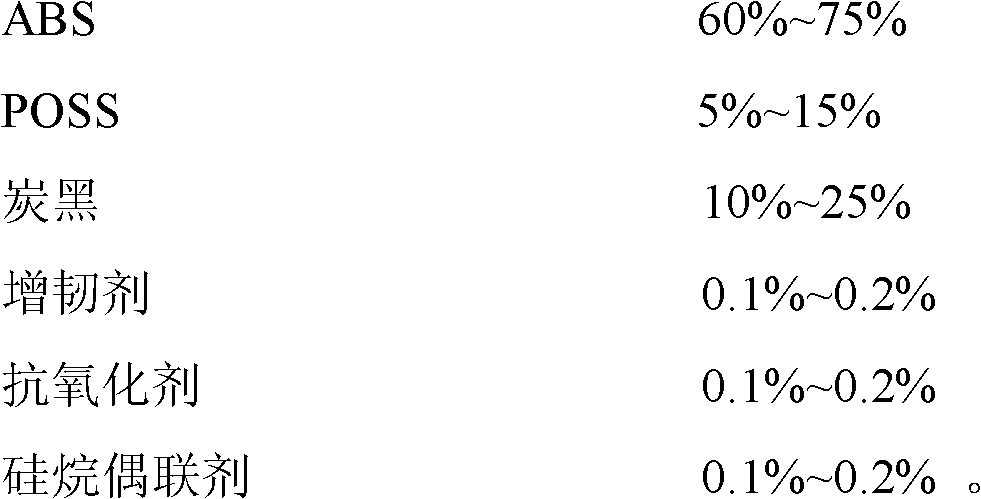

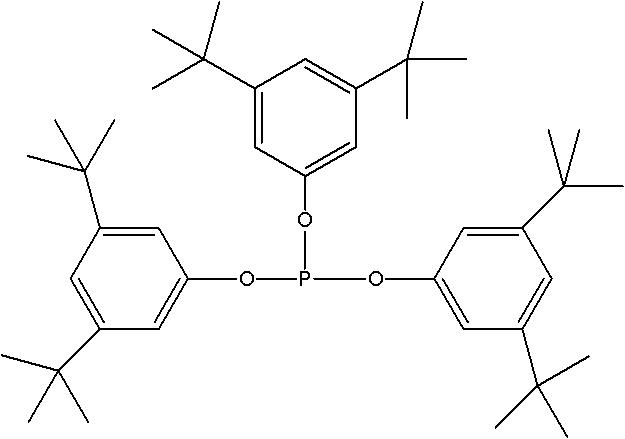

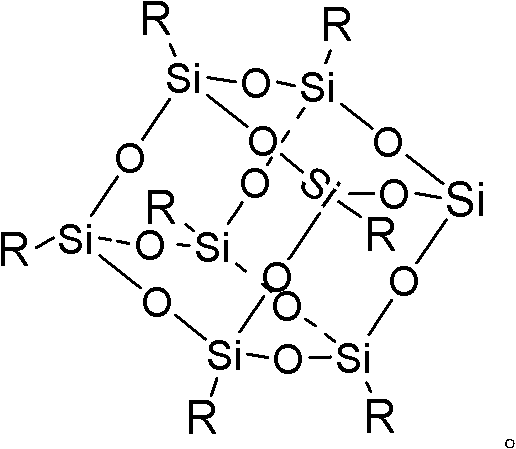

[0024] The raw material ABS resin (U.S. Dow Chemical Company, brand Caliber 201-10, melt index: 10g / 10min) was dried at 90°C for 2h; carbon black (Cabot Company, BP800) was heated at 600°C for 2h to remove organic matter on the surface, Activated carbon black. The dried ABS resin is used as the matrix, the tensile strength of the ABS resin is 40-60MPa, and the notched impact strength of the Charpy beam is 25-35kJ / m2. Carbon black is used as the conductive filler, the specific surface area of the carbon black is 254m2 / g, and the particle size is 45μm. The contents of ABS resin, carbon black and other components are as shown in Table 1. According to the consumption in Table 1, the dried ABS resin, POSS (U.S. Hybrid Plastic Company, CAS No.: 17865-85-9), activated Carbon black, POE-g-MAH (Guangzhou Yuanfeng New Material Co., Ltd.), tris(2,4-di-tert-butylphenyl) phosphite (white crystalline powder, melting point 180-186°C, Aladdin reagent, CAS: 31570 -04-4), KH-550 (Nanjing Ne...

Embodiment 4~6

[0030] The raw material ABS resin (U.S. Dow Chemical Company, brand Caliber 201-10, melt index: 10g / 10min) was dried at 80°C for 4h; carbon black (Cabot Company, BP800) was heated at 700°C for 1h to remove organic matter on the surface, Activated carbon black. The dried ABS resin is used as the matrix, the tensile strength of the ABS resin is 40-60MPa, and the notched impact strength of the Charpy beam is 25-35kJ / m2. With carbon black as conductive filler, the specific surface of carbon black is 254m 2 / g, particle size 45μm. ABS resin and carbon black and other each component content are as shown in table 3, according to the consumption in table 3 the ABS resin after drying, POSS (U.S. Hybrid Plastic company, CAS number: 17865-85-9), activated Carbon black, POE-g-MAH (Guangzhou Yuanfeng New Material Co., Ltd.), tris(2,4-di-tert-butylphenyl) phosphite (white crystalline powder, melting point 180-186°C, Aladdin reagent, CAS: 31570 -04-4), KH-560 (Nanjing Nengde Chemical Co., ...

Embodiment 7~8

[0036] The raw material ABS resin (U.S. Dow Chemical Company, brand Caliber 201-10, melt index of 10g / 10min) was dried at 85°C for 3h; carbon black (Cabot Company, BP800) was heated at 650°C for 1.5h to remove organic matter on the surface , activated carbon black. The dried ABS resin is used as the matrix, the tensile strength of the ABS resin is 40-60MPa, and the notched impact strength of the Charpy beam is 25-35kJ / m2. With carbon black as conductive filler, the specific surface of carbon black is 254m 2 / g, particle size 45μm. The contents of ABS resin, carbon black and other components are as shown in Table 5. According to the consumption in Table 5, the dried ABS resin, POSS (U.S. Hybrid Plastic Company, CAS No.: 17865-85-9), activated Carbon black, POE-g-MAH (Guangzhou Yuanfeng New Material Co., Ltd.), tris(2,4-di-tert-butylphenyl) phosphite (white crystalline powder, melting point 180-186°C, Aladdin reagent, CAS: 31570 -04-4), A-171 (Nanjing Nengde Chemical Co., Ltd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com