Heat treatment method of Hastelloy casting

A heat treatment method and technology of Hastelloy, applied in the field of heat treatment processing, can solve the problems of inability to improve the quality of castings, hot cracks, heat treatment deformation, etc., and achieve good economic benefits, cost reduction, and reduction of thermal deformation and hot cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The chemical composition of Hastelloy alloy is:

[0024] C mn P S Si Cr Mo V Fe N 0.02 0.8 0.020 0.018 0.5 20.5 12.5 0.15 4.0 3

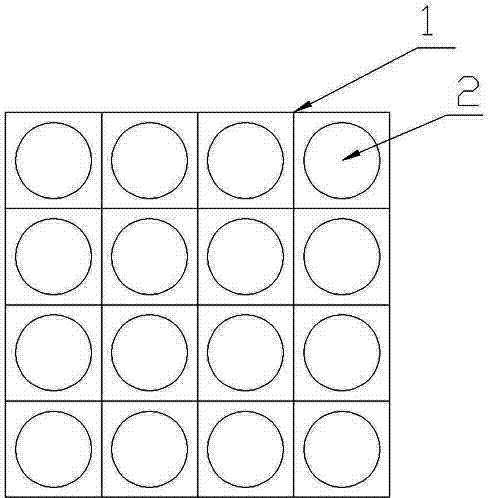

[0025] The solid melting temperature of Hastelloy castings is set at 1050°C, and the holding time is 1.5 hours. The castings are placed under control before heating in the high-temperature furnace to prevent the heat treatment deformation of equipment components from affecting the deformation of the castings, such as figure 1 As shown, the reinforcement ring 1 is used to alternate the castings 2 and place them layer by layer. Then put the Hastelloy casting into a high-temperature furnace for heating, and before loading the furnace, coat the surface of the casting with an oxidation coating to prevent excessive oxidation and thermal cracks on the surface of the casting. The composition of the oxidation coating is refractory mud: zircon powder: water with a mass ratio ...

Embodiment 2

[0028] The difference from the first embodiment is that the chemical composition of the Hastelloy alloy is different and the control parameters are different.

[0029] The chemical composition of Hastelloy alloy is:

[0030] C mn P S Si Cr Mo V Fe N 0.02 0.85 0.020 0.020 0.6 21 12.7 0.15 4.5 3

[0031] The solid melting temperature of Hastelloy castings is set at 1100°C, and the holding time is 1.5 hours. Put the Hastelloy castings into a high-temperature furnace for heating, and quickly immerse the castings in 30°C water to cool after coming out of the furnace.

Embodiment 3

[0033] The difference from the first embodiment is that the chemical composition of the Hastelloy alloy is different and the control parameters are different.

[0034] The chemical composition of Hastelloy alloy is:

[0035] C mn P S Si Cr Mo V Fe N 0.02 0.8 0.02 0.02 0.8 21.5 13 0.25 4.8. 3

[0036] The solid melting temperature of Hastelloy castings is set at 1150°C, and the holding time is 1.5 hours. Put the Hastelloy castings into a high-temperature furnace for heating, and quickly immerse the castings in 20°C water to cool after coming out of the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com