Method for preparing cationic hemicellulose through initiation of plasma

A hemicellulose and plasma technology, applied in the field of ion-induced preparation of cationic hemicellulose, can solve the problems of inability to prepare cationic hemicellulose with a higher degree of substitution, low, generally only 0.01 to 0.02, and limited application, etc. High degree of substitution, improved hydrophilicity, and shortened extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

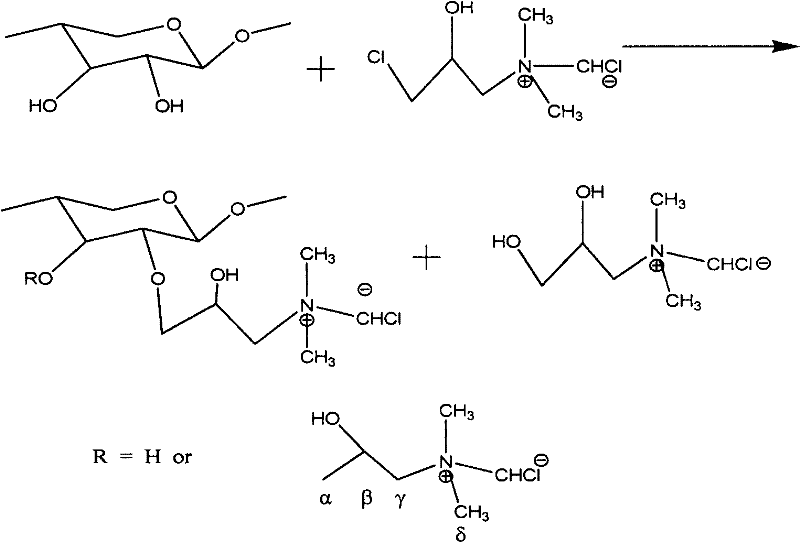

[0025] 2) Preparation of cationic hemicellulose

[0026] A certain amount of hemicellulose obtained in step 1) is placed in a low-temperature plasma reaction chamber for low-temperature plasma treatment. The low-temperature plasma treatment conditions are: treatment voltage 100-200V, vacuum degree 900-2000Pa, and discharge time 40-200s. Then add 1g of the treated hemicellulose into 30mL of water, place it in an ultrasonic reactor with a reaction power of 400-700W, dissolve it at 60°C for 30min under stirring conditions, and add 50mL of ethanol and water by volume after cooling down to 30°C Mixed solution with a ratio of 4:1, then add NaOH at a ratio of 0.1 to 2:1 to alkalinize at 30°C for 20 minutes, then raise the temperature to 60°C The mass ratio of the cationic etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride is added in a ratio of 0.5 to 2:1 for reaction, and the etherification reaction time is 0.5 to 3 hours. After cooling down to room temperature...

Embodiment 1

[0029] 1) Extraction of hemicellulose:

[0030] Take 20g of bagasse raw material and 6g of sodium chlorite and add them into 650ml of water, react at 75°C for 1 hour in an acidic environment, then add 6g of sodium chlorite, and continue the reaction for 1 hour to remove lignin to obtain cellulose, and the obtained synthetic The cellulose is placed in a KOH solution with a mass percentage concentration of 8%, solid g: liquid mL=1:20, and then placed in an ultrasonic pulverizer to strengthen the hedromic cellulose, with ultrasonic power 200W and temperature 20°C. After reacting for 20 minutes, filter with a G2 filter, take the filtrate, and neutralize the filtrate with 6mol / L acetic acid to a pH of 5.5, precipitate and filter with ethanol three times the volume of the above solution, and then acidify the solution with a volume concentration of 80%. After washing with ethanol, vacuum-dry at 60°C for 24 hours to obtain hemicellulose.

[0031]The applicant has measured that the ma...

Embodiment 2

[0036] 1) Extraction of hemicellulose:

[0037] Take 20g of moso bamboo raw material and 6g of sodium chlorite and add it to 650ml of water, react at 75°C for 1 hour in an acidic environment, then add 6g of sodium chlorite, and continue the reaction for 1 hour to obtain cellulose by removing lignin. The cellulose is placed in a KOH solution with a mass percentage concentration of 8%, solid g: liquid mL=1:20, and then placed in an ultrasonic pulverizer to strengthen the hedromic cellulose, with an ultrasonic power of 900W and a temperature of 30°C. After reacting for 200 minutes, filter with a G2 filter, take the filtrate, and neutralize the filtrate with 6mol / L acetic acid to a pH of 5.5, then precipitate and filter with ethanol three times the volume of the above solution, and use an acidified volume concentration of 80% Washed with ethanol and dried in vacuum at 60°C for 24 hours to obtain hemicellulose.

[0038] The applicant has measured that the mass of the hemicellulose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com