Magnesium alloy/biological ceramic bone bracket based on photocuring and gel casting and forming method of bone bracket

A bioceramic, gel injection molding technology, applied in bone implants, medical science, prostheses, etc., can solve the problems of insufficient mechanical strength and stability, mismatch of strength degradation rate and bone reconstruction process, etc. Insufficient early mechanical strength and stability, enhancing early mechanical properties, and reducing the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

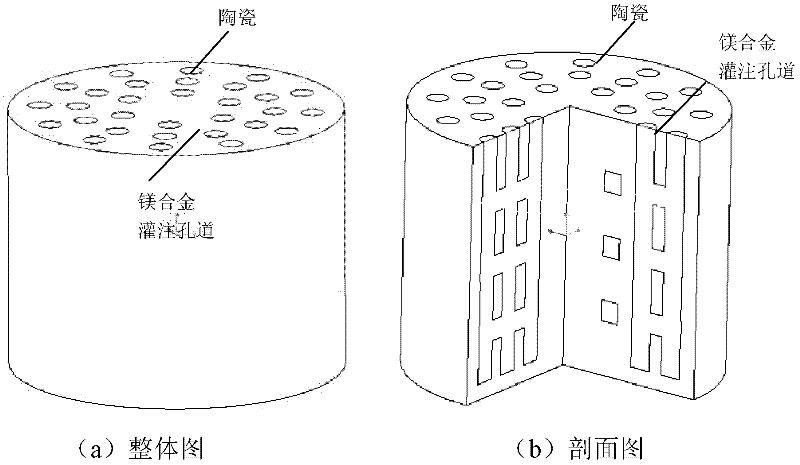

[0021] see figure 1 , 1) Firstly, according to the specific situation of the patient's bone defect site, the shape correlation and microstructure bionic design of the bone defect site are carried out with the help of reverse engineering and CAD technology, and the force, internal deformation and hydrodynamic characteristics of the bracket are analyzed by CAE analysis software and structural modifications to form a CAD model of a biomimetic scaffold with a connected internal microstructure;

[0022] 2) Using layering software to layer the CAD model of the bionic bracket, the layer thickness is 0.10mm, and use the light curing molding machine to make the negative resin mold of the bracket according to the layered results;

[0023] Among them, the wavelength of the laser of the light curing molding machine is 355nm; the spot diameter is 0.2mm; the filling scanning speed is 5000mm / s; the filling vector spacing is 0.10mm; the supporting scanning speed is 2000mm / s; the jumping speed...

Embodiment 2

[0027] Embodiment 2: Ceramic slurry is prepared according to the following method in the present embodiment, and other steps are with embodiment 1:

[0028] Ceramic powder Alpha-tricalcium phosphate (α-TCP), water solvent deionized water, organic monomer methyl-acyloxyethyltrimethylammonium chloride, dispersant ammonium polyacrylate and crosslinking agent N, N- Diacetone acrylamide is mixed evenly at a mass ratio of 120:80:8:1:1, put into a vacuum machine to remove air bubbles, and adjust the pH of the mixture to 9 with concentrated ammonia water to obtain a slurry, and then add The initiator sodium persulfate with 0.5 times the weight of the crosslinking agent and the catalyst N,N-dimethylcyclohexylamine form a ceramic slurry.

Embodiment 3

[0029] Embodiment 3: Ceramic slurry is prepared according to the following method in the present embodiment, and other steps are with embodiment 1:

[0030] Ceramic powder apatite, water solvent deionized water, organic monomer adipate dihydrazide, dispersant sodium polyacrylate and cross-linking agent dibenzylidene acetonyl acrylamide according to the ratio of 115:60:7:1.5:1.5 The mass ratio of the mixture is evenly mixed, put into a vacuum machine to remove air bubbles, and adjust the pH of the mixture to 9 with concentrated ammonia water to obtain a slurry, and then add initiator potassium persulfate and catalyst N , N, N', N", N"-pentamethyldiethylenetriamine forms a ceramic slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com