A kind of inorganic polymer sludge solidification mortar and preparation method thereof

An inorganic polymer, sludge technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of large use of cement, high temperature maintenance, low early strength, etc., to save labor costs, save The effect of template acquisition cost and material cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

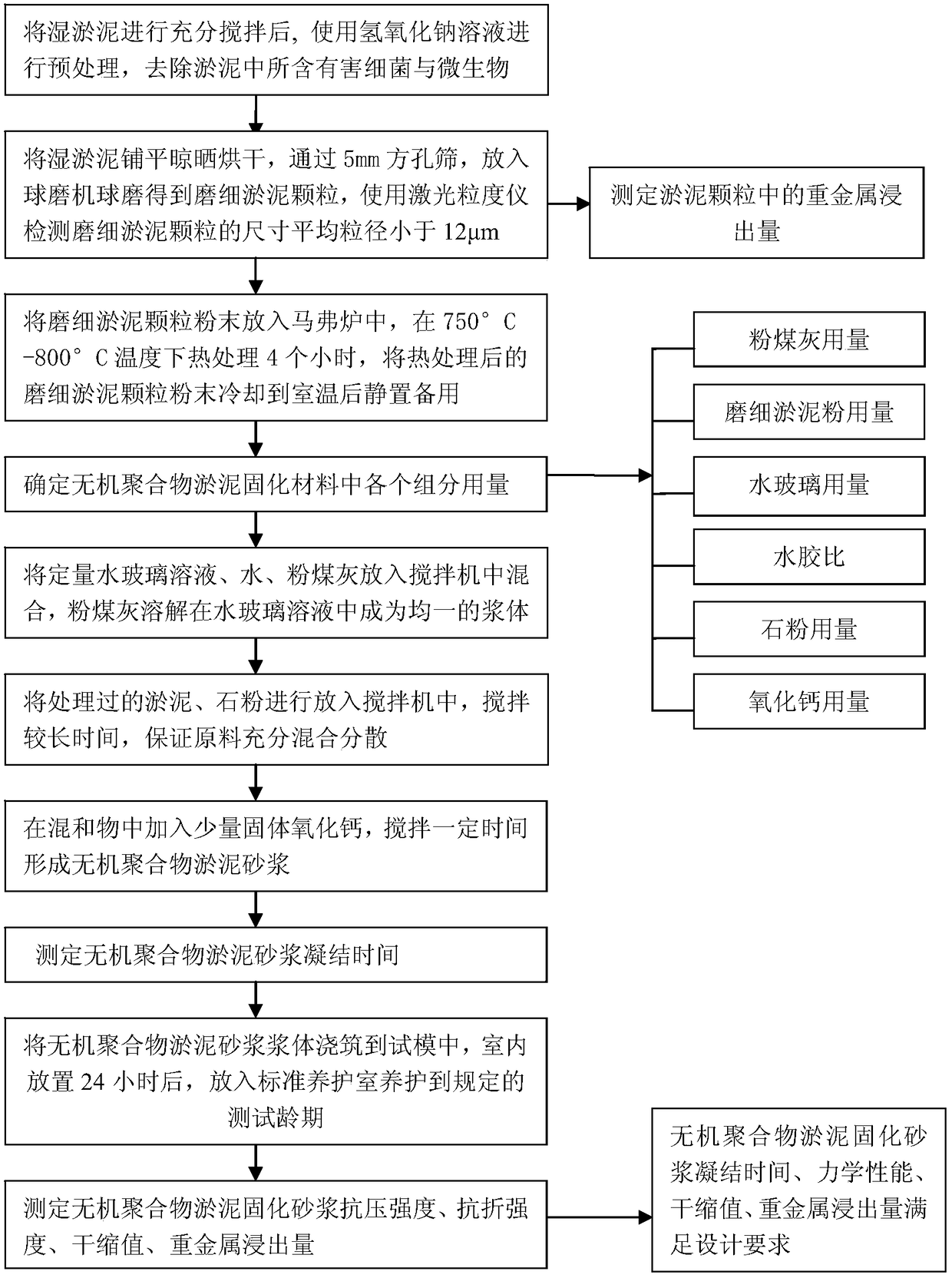

Method used

Image

Examples

Embodiment 1

[0031] 1. Pretreatment of sludge

[0032] After fully stirring the wet silt produced by river dredging and reclamation projects, soak it in 20% sodium hydroxide solution for 8 hours to remove harmful bacteria and microorganisms contained in the silt. Then pave the treated wet silt and place it in a sunny and well-ventilated open space for about a week. Manually pulverize the dried sludge and pass through a 5mm square hole sieve to remove impurities and irregular particles in the sludge. The dried sludge particles were put into a ball mill with a volume of 10 L and ball milled at a speed of 30 rpm for 20 minutes. The ground sludge particles were sealed and placed for 48 hours. The average size of the ground sludge particles was measured by a laser particle size analyzer to be 11.578 μm. Put the finely ground sludge particle powder into a 5L muffle furnace, heat up to 750-800°C at a rate of 5°C / min, heat treatment at this temperature for 4 hours, then cool the sludge particle p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com