Chlorination method for phenoxyacetic acid

A technology of phenoxyacetic acid chloride and phenoxyacetic acid, applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of poor selectivity, environmental pollution, high cost, etc., achieve reduction of preparation cost, simple method steps, and easy operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

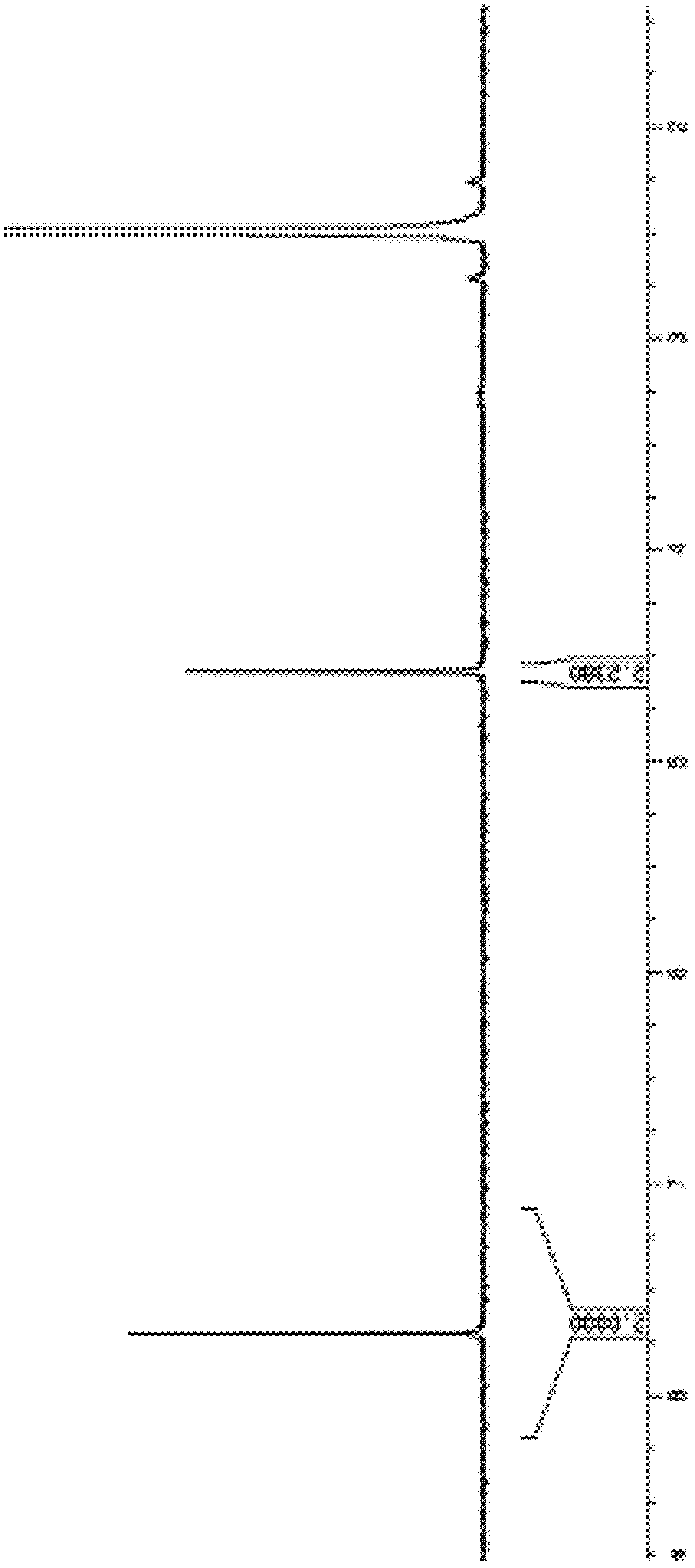

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: present embodiment provides a kind of chlorination method of phenoxyacetic acid, specifically completes according to the following steps:

[0010] 1. Preparation of phenoxyacetic acid solution: add phenoxyacetic acid to an organic solvent to form a phenoxyacetic acid solution with a mass-volume concentration of 5 to 150 g / L; 2. Electrolysis: add the phenoxyacetic acid solution prepared in step 1 to the single In the hydrochloric acid solution of the chamber electrolytic cell, obtain the phenoxyacetic acid electrolyte, then turn on the power supply, adjust the current intensity to 0.1A-0.4A, and electrolyze the chlorination at room temperature with a voltage of 1.1V-2V for 2-10 hours, and obtain the electrolytic 3. Purification: the reaction solution after step two electrolysis is processed by vacuum distillation to obtain the crude product of phenoxyacetic acid chloride, and then the crude product of phenoxyacetic acid chloride is processed by re...

specific Embodiment approach 2

[0016] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass-volume concentration of the phenoxyacetic acid solution prepared in Step 1 is 14-140 g / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of HCl in the hydrochloric acid solution described in step 2 is 36%. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com