Preparation method of recyclable surface film of inferior vena cava filter based on (PEG) polyethylene glycol-like

A polyethylene glycol, vena cava technology, applied in the direction of filter, ion implantation plating, coating, etc. in blood vessels, can solve the problems of chemical modification of difficult vena cava filter, etc., to improve biological decontamination performance and improve stability long-lasting, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

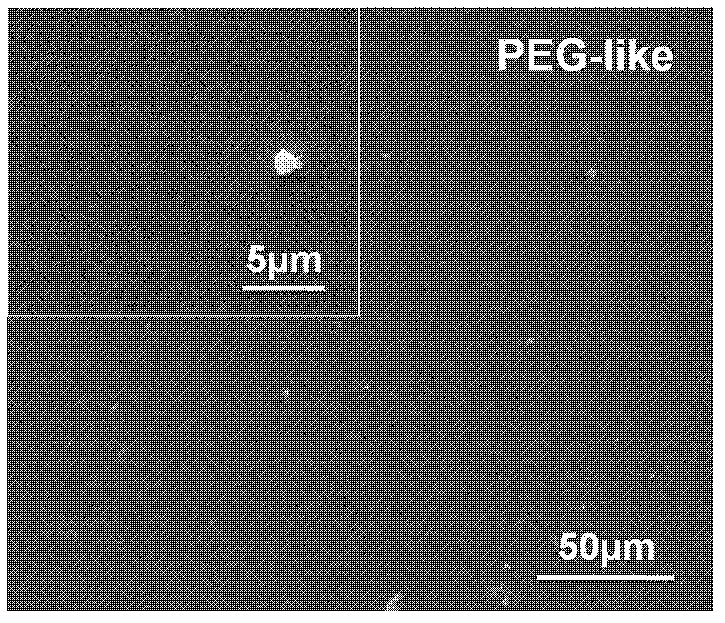

[0027] Put the inferior vena cava filter made of 316L stainless steel into the plasma polymerization vacuum chamber. When the vacuum is evacuated to 0.5 Pa, argon gas with a flow rate of 2.5 sccm is introduced, and the radio frequency power is 100W, and the negative bias voltage is 80V. 15 minutes of sputtering cleaning; after the sputtering cleaning is completed, the vacuum chamber is re-pumped to 0.5Pa, and then the reaction gas tetraethylene glycol dimethyl ether is introduced to make the working pressure 2Pa, the RF power is 5W, and the negative bias is - Under the conditions of 80V and pulse duty ratio of 10%, the plasma polymerization thin film deposition was carried out for 30 minutes, that is, a polyethylene glycol (PEG-like) functional thin film with a thickness of 25 nm was deposited on the surface of the inferior vena cava filter.

Embodiment 2

[0029] Put the inferior vena cava filter made of NiTi shape memory alloy (Ni to Ti atomic ratio 50%) into the plasma polymerization vacuum chamber. 100W, 15 minutes of sputter cleaning under the condition of negative bias voltage of 80V; after the sputter cleaning is completed, the vacuum chamber is re-pumped to 0.5Pa, and then the reaction gas tetraethylene glycol dimethyl ether is introduced to make the working pressure 5Pa , the radio frequency power is 30W, the negative bias voltage is -80V, and the pulse duty ratio is 100% under the conditions of 120 minutes of plasma polymerization film deposition, that is, the deposition thickness of 100nm polyethylene glycol on the surface of the inferior vena cava filter ( PEG-like) functional film.

Embodiment 3

[0031] Put the inferior vena cava filter made of 316L stainless steel into the plasma polymerization vacuum chamber. When the vacuum is evacuated to 0.5 Pa, argon gas with a flow rate of 2.5 sccm is introduced, and the radio frequency power is 100W, and the negative bias voltage is 80V. 15 minutes of sputtering cleaning; after the sputtering cleaning is completed, the vacuum chamber is re-pumped to 0.5Pa, and then the reaction gas tetraethylene glycol dimethyl ether is introduced to make the working pressure 3Pa, the RF power is 15W, and the negative bias is - Under the conditions of 80V and pulse duty ratio of 30%, the plasma polymerization film deposition was carried out for 60 minutes, that is, a polyethylene glycol (PEG-like) functional film with a thickness of 50nm was deposited on the surface of the inferior vena cava filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com