Abrasive soymilk grinder and stalling-prevention method thereof

A soymilk machine and anti-blocking technology, applied in milk substitutes, beverage preparation devices, household appliances, etc., can solve problems such as overheating, increased crushing effect, threats, etc., achieve the effect of convenient use and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

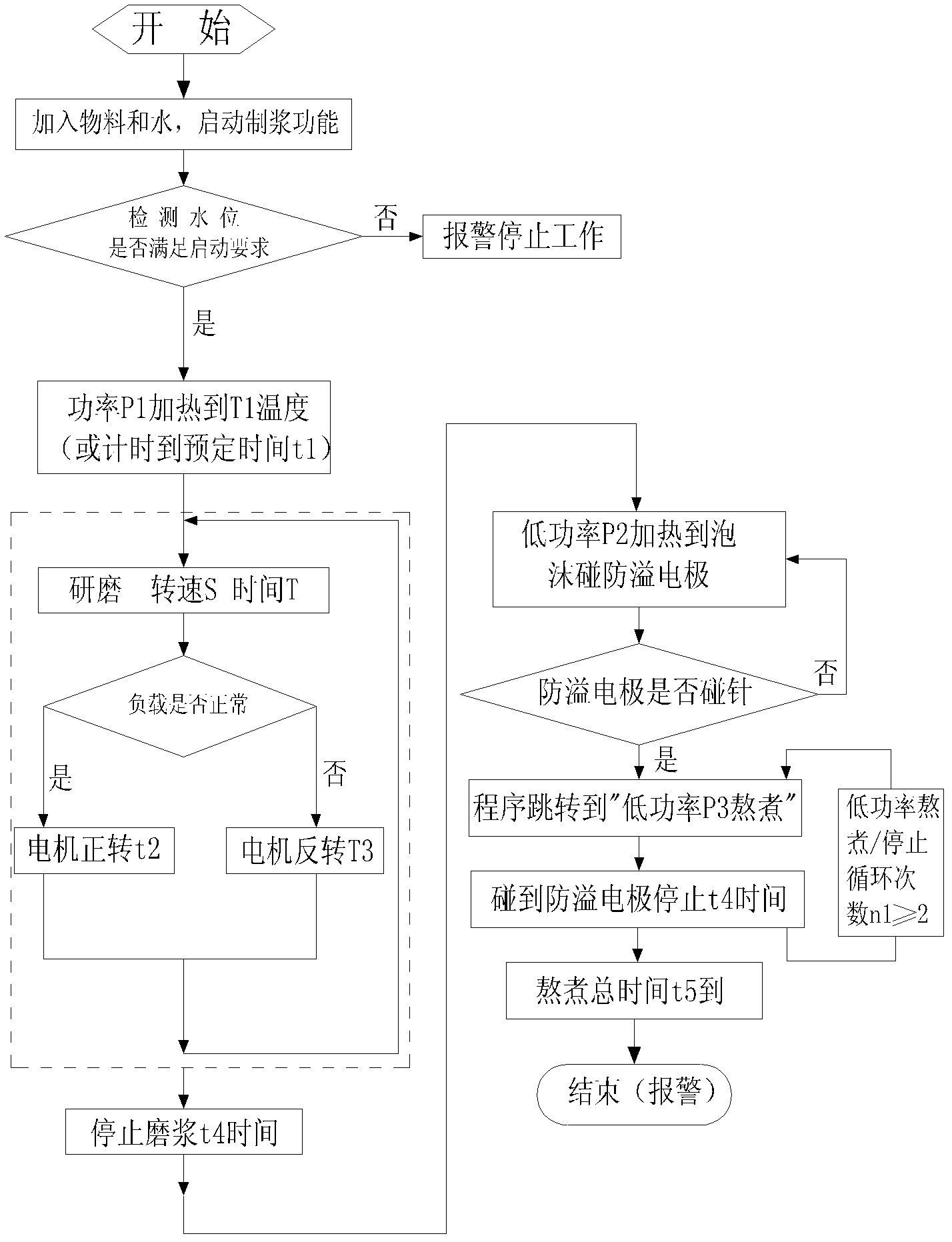

Method used

Image

Examples

Embodiment 1

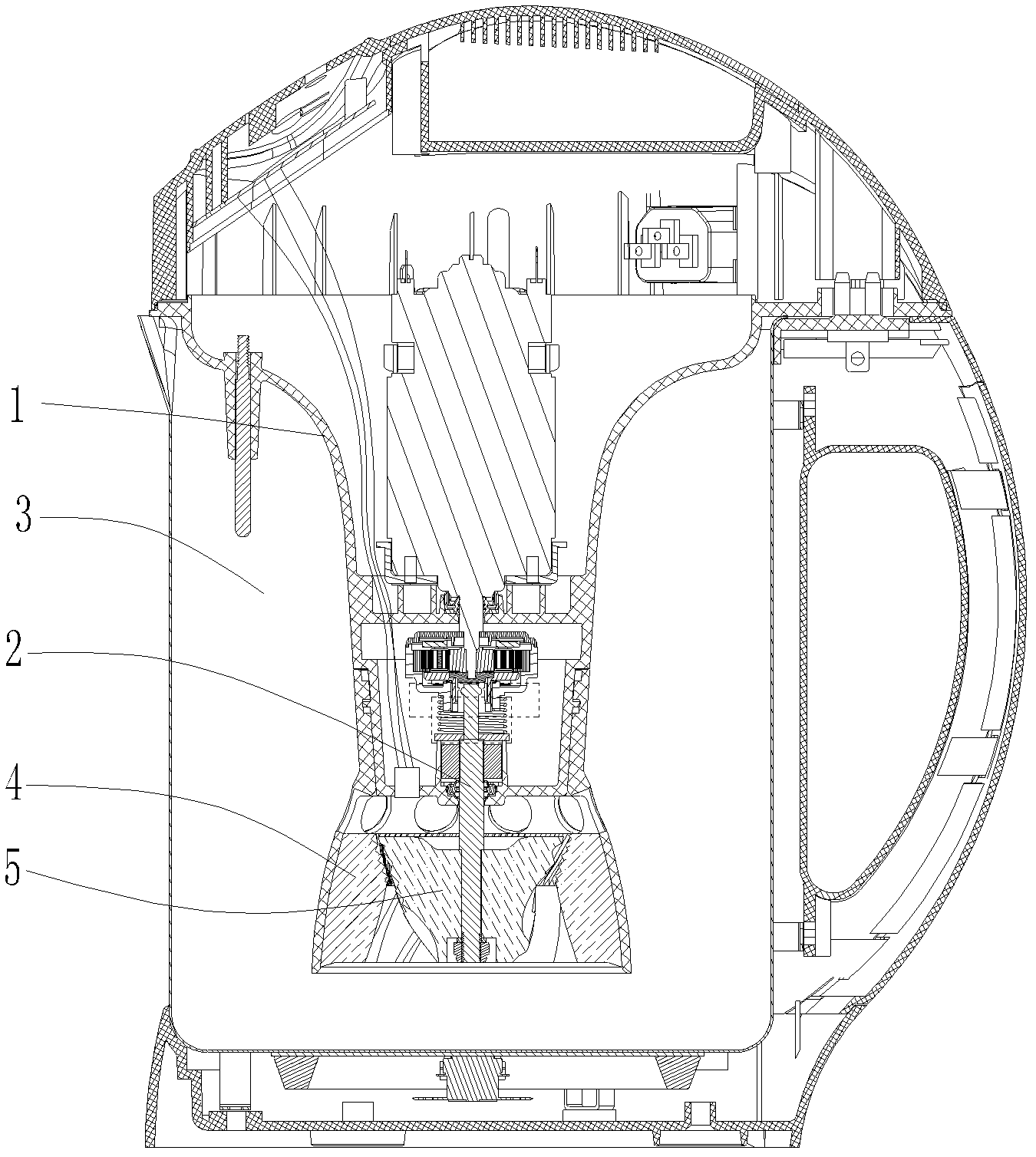

[0034] Such as figure 1 , image 3 , Figure 4 As shown, a soymilk grinder includes a pulp container 3 and a cup cover 1 buckled in the pulp container 3. A motor is fixed inside the cup cover 1. The motor shaft 2 of the motor extends into the pulp container 3. The cup cover 1 The lower part is connected with a static grinding assembly including a static grinding head 4, and the motor shaft 2 is provided with a dynamic grinding head 5 matched with the static grinding head 4, which also includes:

[0035] A processor unit, which has a control chip that stores programs that can control the corresponding operating modes of the motor according to different material handling modes;

[0036] An input control unit has a plurality of switches to select different material processing modes, and its control commands are sent to the processor unit to control and command the working modes of all the electromechanical parts of the soymilk grinder to perform the operations selected by the u...

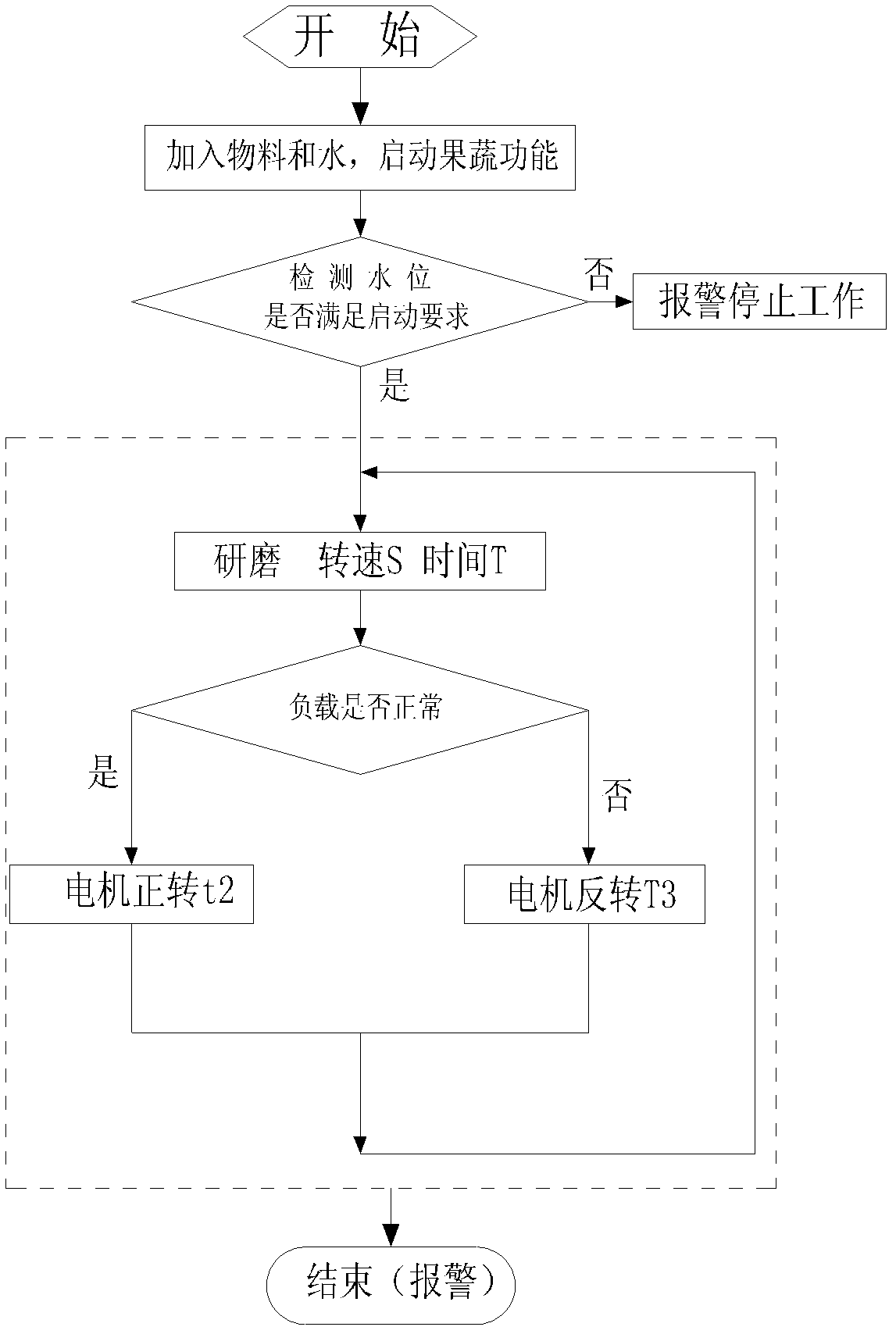

Embodiment 2

[0052] Such as figure 2 As shown, a kind of anti-blocking method for grinding soybean milk machine is specifically implemented in the process of beating fruits and vegetables, including the following stages:

[0053] a). In the feeding stage, liquid and materials are added to the slurry container at the same time;

[0054] b). In the stage of liquid level detection, the processor unit detects the liquid level in the container, and the processor makes a judgment on the water level. If the water level reaches the minimum water level line, it enters the next stage, otherwise it will give an alarm;

[0055] c). During the fruit and vegetable anti-blocking stage, by giving the motor a specific power value within a certain period of time and controlling the forward and reverse rotation, the fruit and vegetable is repeatedly beaten; until the fruit and vegetable beating program is completed and the alarm ends. Other modes are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com