Method for preparing high-electric-conductivity pure copper strips for transformer

A high-conductivity, transformer-based technology, applied in the field of preparation of high-conductivity pure copper strips for transformers, can solve the problems of harsh parameters of pure copper strips, achieve less intermediate annealing times, short production process, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

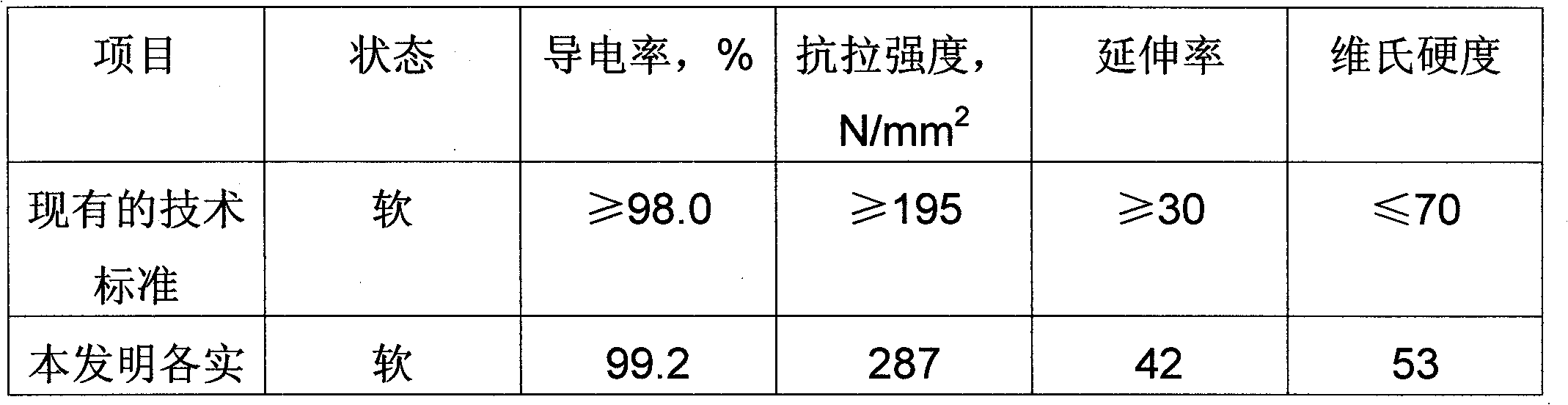

Examples

Embodiment 1

[0018] Firstly, the proportioning raw materials are needed, because the present invention requires that the electrical conductivity of the final cost copper strip needs to be more than 98%, so impurity elements such as phosphorus and iron that can affect the conductivity of the pure copper strip need to be strictly controlled when proportioning the raw materials. In this embodiment, the copper content of the raw material is 99.9%, the phosphorus content is 0.003%, and the iron content is 0.005%.

[0019] After determining the ratio of raw materials, the raw materials are sent to the furnace for melting. The charge melting temperature is raised to 1150°C to 1300°C in the atmosphere. High-purity copper is easy to suck air into the raw material during the melting process, causing air bubbles to form inside the raw material, so it needs to be added to the middle of the alloy in the melted raw material. In this embodiment, copper-phosphorus master alloy (phosphorus: 8.0%; iron: 0....

Embodiment 2

[0024] Proportioning raw materials, in this embodiment, the copper content of the raw materials is 99.93%, the phosphorus content is 0.002%, and the iron content is 0.003%.

[0025] After determining the ratio of raw materials, the raw materials are sent to the furnace for melting. The furnace charge melting temperature is raised to 1200°C to 1300°C in the atmosphere. High-purity copper is easy to absorb air into the raw material during the melting process, causing air bubbles to form inside the raw material, so an intermediate alloy needs to be added to the melted raw material. In this embodiment, the master alloy is copper-phosphorus master alloy (phosphorus: 9.0%; iron: 0.15%; copper balance). The content of the copper-phosphorus master alloy is 0.01%. The copper-phosphorus master alloy is firstly heated to a molten state and then added to the liquid raw material.

[0026] Stir the liquid raw materials with wooden sticks or plastic rods, so that the copper-copper-phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com