Process for producing sintered sialon ceramic

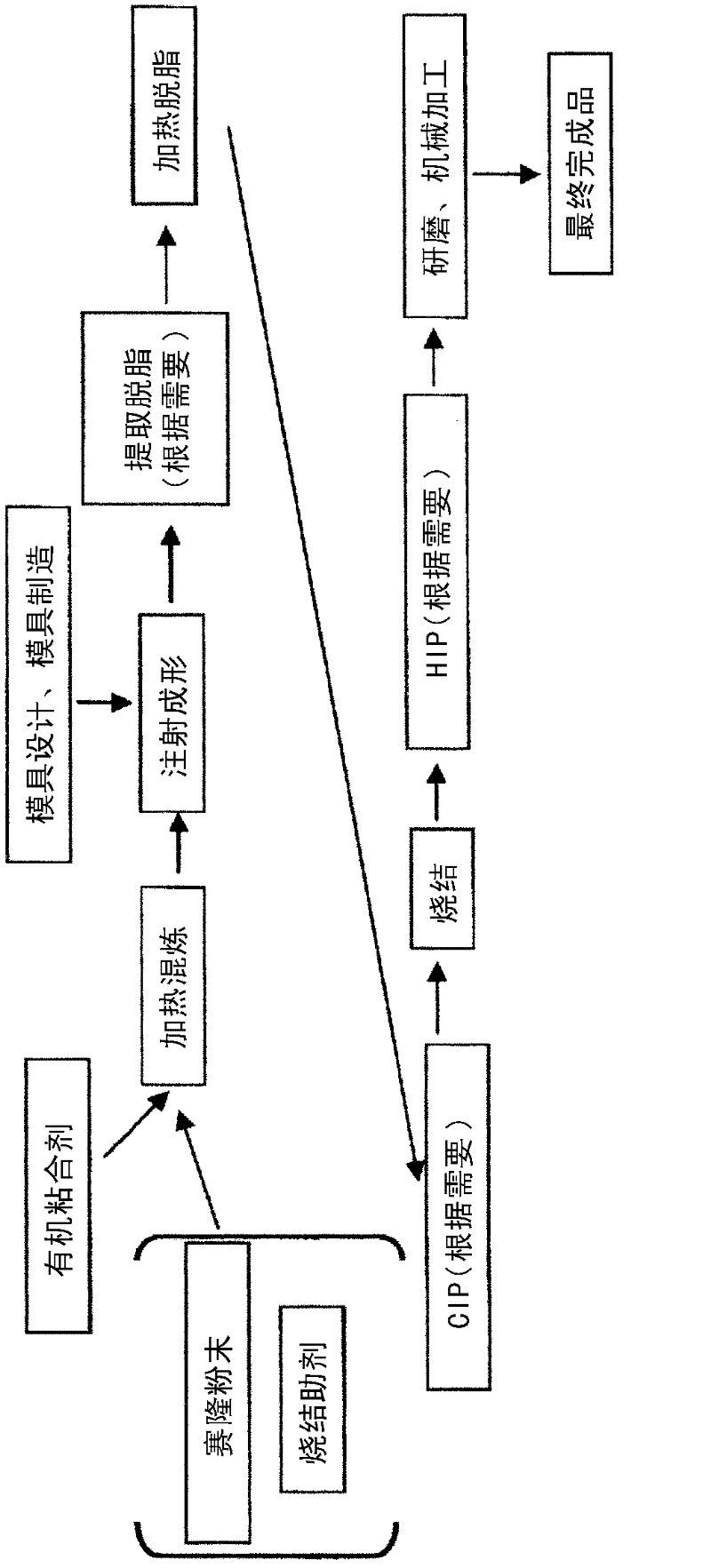

A manufacturing method, Sialon's technology, applied in the supporting elements of blades, nanotechnology for material and surface science, nanotechnology, etc., can solve problems such as difficulty in obtaining three-dimensional complex shapes, and achieve the effect of good dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

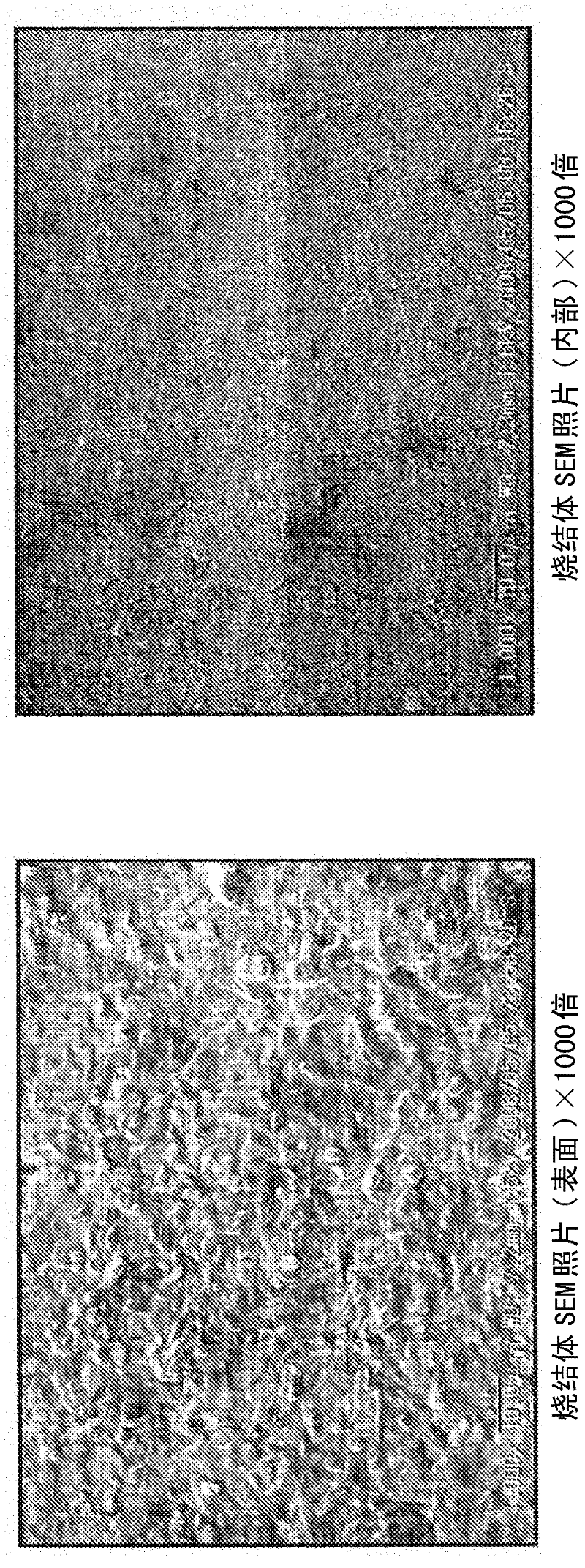

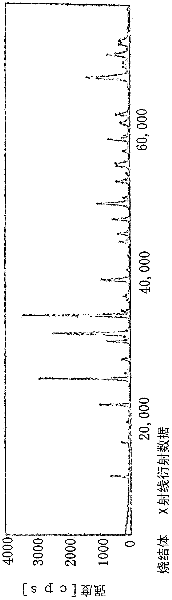

[0100] Sialon ceramic sintered products were produced by the method of the present invention. Molding materials, heating and kneading conditions, injection molding conditions, degreasing conditions, sintering conditions, etc. are as follows. 100 compacts of 35 mm x 35 mm x 3 mm were formed, and degreasing, presence or absence of defects after sintering, and measurement of sintered density were performed.

[0101] The average particle size of sialon powder is 0.5μm (composition formula Si 5 AlON 7 )

[0102] ·Sintering aid: yttrium oxide

[0103] Organic binder composition: PVB (molecular weight 15,000) 15 volume%, PEG (molecular weight 2,000) 45 volume%, amorphous polyolefin 5 volume%, polybutylmethacrylate 15 volume%, ethylene vinyl acetate copolymer Stearic acid 15 volume %, stearic acid 5 volume %

[0104] ・Sialon powder: 90% by weight Yttrium oxide: 10% by weight

[0105] Molding material: organic binder 48% by volume Sialon powder + sintering aid 52% by volume

[0...

Embodiment 2

[0136] Various researches and experiments were conducted on the types and amounts of sintering aids and the composition of organic binders. The molding conditions, extraction degreasing conditions, drying conditions, and heating degreasing conditions were carried out under the same conditions as in Example 1. The conditions and results used in the experiment are shown in Tables 2-4.

[0137] 【Table 2】

[0138] Compounding of powder (sialon powder and sintering aid)

[0139]

[0140] 【table 3】

[0141] Composition of organic binder (vol%)

[0142] PVB15000

PVB180000

PEG1500

PEG2000

PEG10000

EVA

APOs

PBMA

St.

a

15

-

-

45

-

5

15

15

5

b

10

-

50

-

-

5

16

16

3

c

3

-

-

50

-

10

16

16

5

d

0

-

-

50

-

15

...

Embodiment 3

[0151] It can be seen from the above examples and other experiments that in order to stably manufacture sialon sintered products with a wall thickness of 1mm or more, it is preferable to use a suitable organic binder (organic binder containing specific PVB and PEG). The extraction and degreasing process is carried out. In order to further study a suitable organic binder, various organic binders were used, except for the composition of the organic binder, in the same manner as in Example 1 to manufacture a product of 35 mm×35 mm×3 mm. The results are summarized in Table 5.

[0152] In addition, the remainder of the organic binder was mixed with EVA, PBMA, and stearic acid in the compounding ratio shown in Table 5.

[0153] 【table 5】

[0154]

[0155] As shown in Table 5, when the amount of PVB added is less than 5% by volume, the strength of the molded body tends to decrease, and when the amount of PVB added exceeds 30% by volume, it remains as carbides during thermal degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com