Membrane electrode based on spiral carbon nanofiber bundle and preparation method thereof

A technology of carbon nanofiber bundles and carbon nanofibers, applied in the field of thin film electrodes based on helical carbon nanofiber bundles and its preparation, to achieve the effects of convenient operation, easy large-scale industrial production, and good electrochemical cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

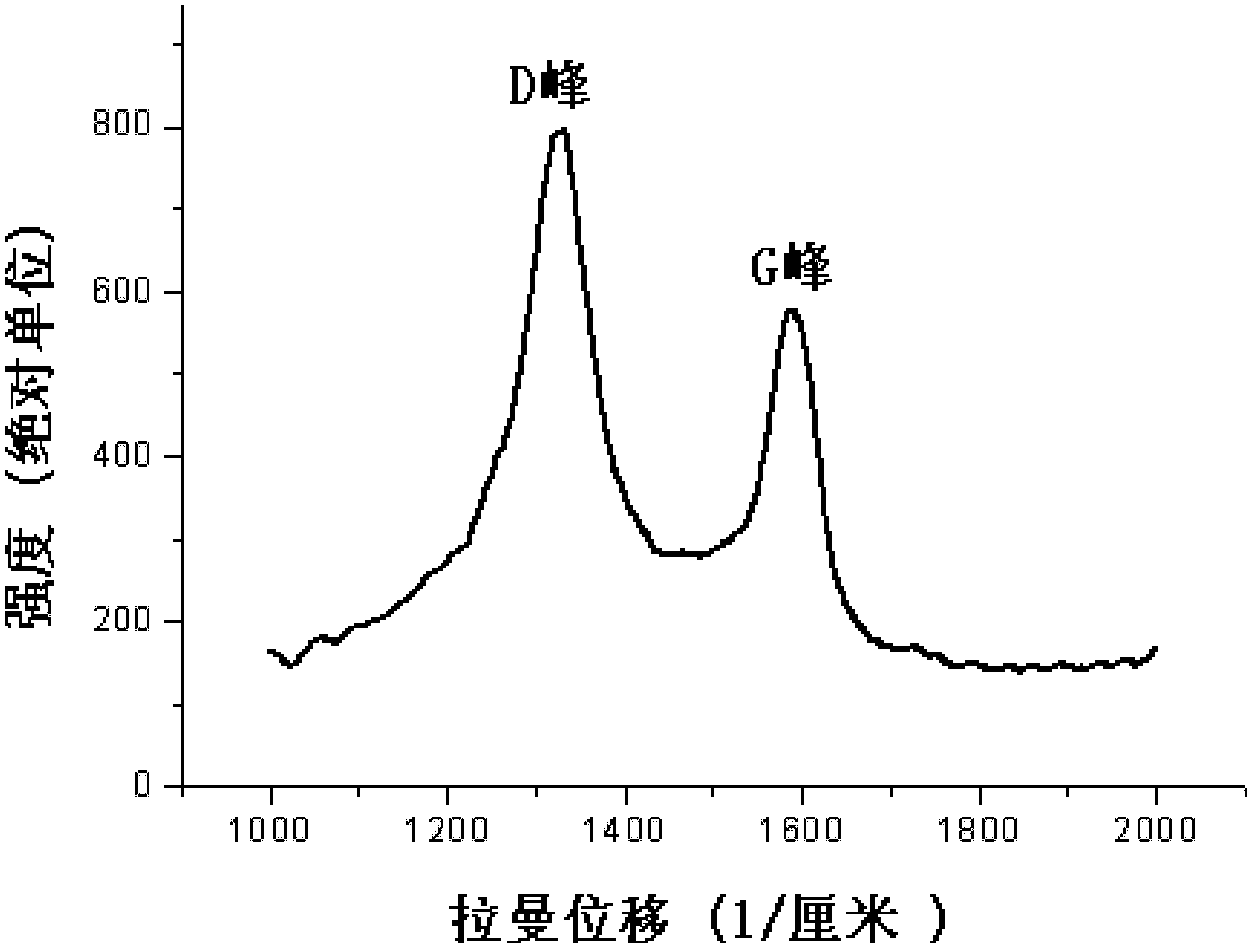

Image

Examples

Embodiment 1

[0024] Cut a copper foil with a thickness of 10 μm into a shape of 2cm×4cm, ultrasonically clean it in ethanol for 10 minutes, immerse it in 20mL ethanol solution containing 0.4g nickel nitrate for 5 minutes, and then dry it in an oven at 50°C for 3 hours. Repeat the above steps for 3 Second, nickel-based catalyst particles are loaded on the surface of copper foil; the copper foil loaded with nickel-based catalyst particles is placed in the high temperature zone of the dual temperature zone tube furnace, and camphor is placed in the low temperature zone of the dual temperature zone tube furnace as a solid carbon source , after sealing the dual temperature zone tube furnace, nitrogen gas is introduced at a flow rate of 50mL / min along the direction from the low temperature zone to the high temperature zone to form an inert gas protective atmosphere in the dual temperature zone tube furnace; The high temperature zone is heated to 760°C, and then the low temperature zone of the dua...

Embodiment 2

[0030] Cut a copper foil with a thickness of 30 μm into a shape of 2cm×4cm, ultrasonically clean it in ethanol for 20 minutes, immerse it in 20mL ethanol solution containing 0.5g nickel nitrate for 4 minutes, and then dry it in an oven at 60°C for 2 hours. Repeat the above steps for 4 Second, nickel-based catalyst particles are loaded on the surface of copper foil; the copper foil loaded with nickel-based catalyst particles is placed in the high temperature zone of the dual temperature zone tube furnace, and camphor is placed in the low temperature zone of the dual temperature zone tube furnace as a solid carbon source , after sealing the dual-temperature-zone tube furnace, argon gas is introduced at a flow rate of 40 mL / min along the direction from the low-temperature zone to the high-temperature zone to form an inert gas protective atmosphere in the dual-temperature zone tube furnace; the dual-temperature zone tube furnace The high temperature zone is heated up to 600°C, and ...

Embodiment 3

[0033] Cut a copper foil with a thickness of 20 μm into a shape of 2cm×4cm, ultrasonically clean it in ethanol for 14 minutes, immerse it in 20mL ethanol solution containing 0.6g nickel nitrate for 3 minutes, and then dry it in an oven at 70°C for 1 hour. Repeat the above steps for 5 Second, nickel-based catalyst particles are loaded on the surface of copper foil; the copper foil loaded with nickel-based catalyst particles is placed in the high temperature zone of the dual temperature zone tube furnace, and camphor is placed in the low temperature zone of the dual temperature zone tube furnace as a solid carbon source , after sealing the dual-temperature zone tube furnace, feed nitrogen gas at a flow rate of 60 mL / min along the direction from the low temperature zone to the high temperature zone, and form an inert gas protective atmosphere in the dual temperature zone tube furnace; The high-temperature zone is heated to 650°C, and then the low-temperature zone of the dual-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com