Process for coproducing aromatic oil, asphalt and fuel oil

A technology for aromatic hydrocarbon oil and fuel oil, applied in the petroleum industry, hydrocarbon distillation and other directions, can solve the problems of waste, low actual utilization efficiency of oil slurry, etc., and achieves ease and control of operating conditions, strong output scale scalability, and short process flow. Immediate and continuous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make full use of the catalytic oil slurry resources in the domestic market and produce high value-added products, technical research was carried out by a special organization, the properties of the catalytic oil slurry produced by multiple factories were analyzed, and several research tests were carried out to grasp its characteristics. Combined with the existing The current situation of the production device, through trial production, the author of the present invention has successfully developed a new process for the co-production of aromatic oil and finished asphalt by catalytic oil slurry continuous distillation.

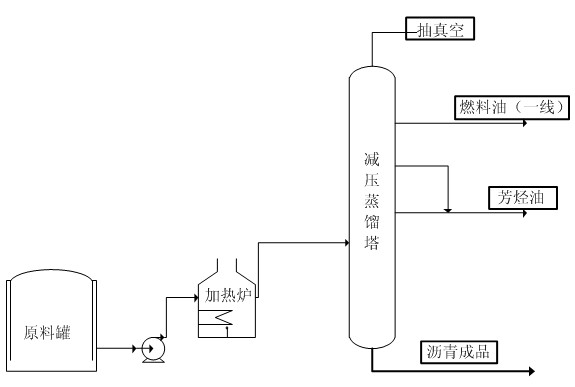

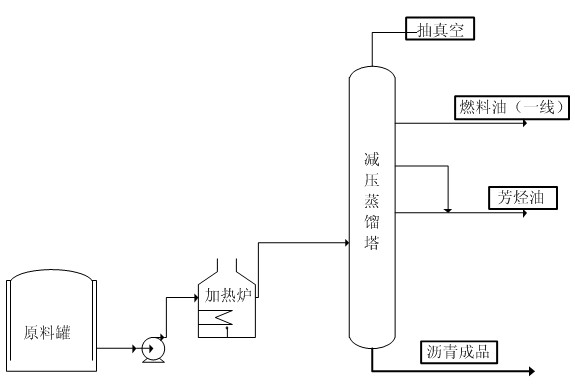

[0015] Such as figure 1 Shown is a schematic flow chart of the co-production process using catalytic oil slurry in the present invention. It can be seen from the figure that the present invention uses catalytic oil slurry as raw material to obtain fuel oil, aromatic oil and asphalt products by continuous vacuum distillation. The specific proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com