Gold-iron alloy interconnection wire and manufacturing method thereof

A technology of gold-iron alloy and production method, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as low resistivity, and achieve the effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

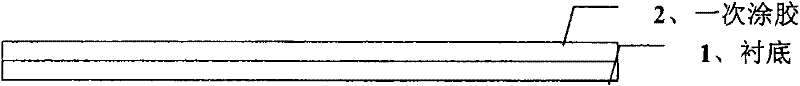

[0035] Such as figure 1 As shown, figure 1 It is a flow chart of a method for manufacturing a gold-iron alloy interconnection wire provided by the present invention, and the method includes:

[0036] Step 1: Solution configuration;

[0037] The content of gold is 4~13g / L, added with potassium gold cyanide; the content of iron is 0.2~1.2g / L, added with potassium ferrocyanide, conductive salt potassium citrate 20~30g / L, brightener sulfuric acid Cobalt is 0.5~1g / L, and the remaining part is supplemented with high purity water;

[0038] Step 2: Clean the semiconductor chip;

[0039] Clean the semiconductor chip with acetone, ethanol and water in sequence;

[0040] Step 3: Coat a layer of photoresist on the cleaned semiconductor c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com