A kind of preparation method of vanadium-based supported denitration catalyst

A denitrification catalyst and supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of easy shrinkage of the surface, small specific surface area, instability, etc., and achieve good surface properties, large specific The effect of surface area and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 0.0259g ammonium metavanadate (NH 4 VO 3 ) was dissolved in oxalic acid solution, 2gγ-Al 2 o3 Dissolve in ammonium tungstate solution, dip in oil bath (80°C) with stirring, evaporate to dryness, and dry in an oven at 110°C for 12 hours. The dried samples were ground and calcined at 500°C for 6h in air atmosphere. That is, 1% V 2 o 5 / γ-Al 2 o 3 .

Embodiment 2

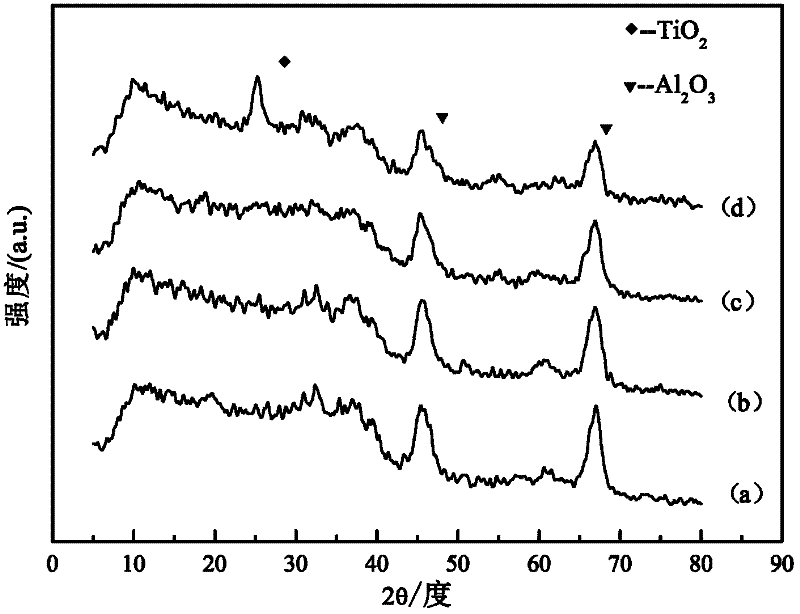

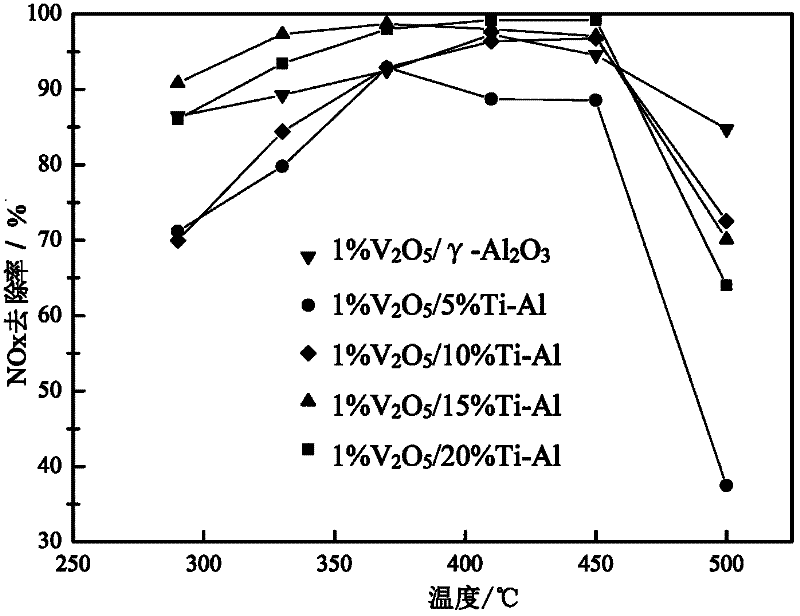

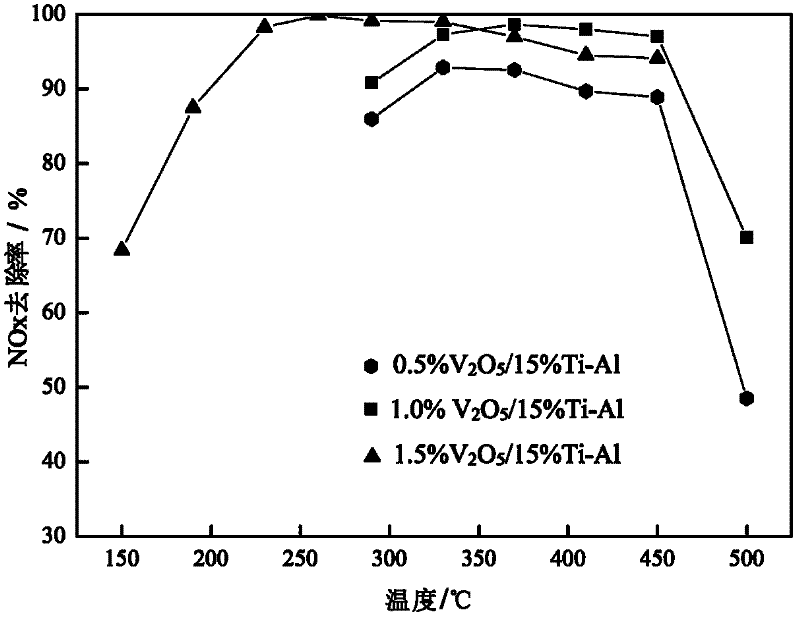

[0032] Immerse 4.75g of γ-Al with 75ml of n-butanol solution containing 1.0652g of n-butyl titanate 2 o 3 Carrier (γ-Al 2 o 3 The carrier was pre-calcined in air atmosphere at 700°C for 6h, and the specific surface area was 156m 2 g -1 ), so that TiO 2 The proportion in the composite carrier is 5%. To make TiO 2 Can be better in γ-Al 2 o 3 Disperse on the surface, control the hydrolysis rate of n-butyl titanate, and make the gel more uniform. The impregnated sample adopts the environment of ice water bath, and the 2 Stir and hydrolyze at 20-30r / s for 24 hours under the protection of the atmosphere. After the reaction is complete, age at room temperature for 24 hours, then evaporate the water in an oil bath (80°C), and bake in an oven at 110°C for 12 hours. The dried samples were ground to 40-60 meshes and then calcined at 600°C for 4 hours in an air atmosphere.

[0033] active species V 2 o 5 The precursor is ammonium vanadate (NH 4 VO 3 ), with 0.0259g NH 4 VO ...

Embodiment 3

[0035] Immerse 4.5g of γ-Al with 75ml of n-butanol solution containing 2.1304g of n-butyl titanate 2 o 3 Carrier (γ-Al 2 o 3 The carrier was pre-calcined in air atmosphere at 700°C for 6h, and the specific surface area was 156m 2 g -1 ), so that TiO 2 The proportion in the composite carrier is 10%. To make TiO 2 Can be better in γ-Al 2 o 3 Disperse on the surface, control the hydrolysis rate of n-butyl titanate, and make the gel more uniform. The impregnated sample adopts the environment of ice water bath, and the 2 Stir and hydrolyze at 20-30r / s for 24 hours under the protection of the atmosphere. After the reaction is complete, age at room temperature for 24 hours, then evaporate the water in an oil bath (80°C), and bake in an oven at 110°C for 12 hours. The dried samples were ground to 40-60 meshes and then calcined at 600°C for 4 hours in an air atmosphere.

[0036] active species V 2 o 5 The precursor is ammonium vanadate (NH 4 VO 3 ), with 0.0259g NH 4 VO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com