Cuazrbalcmd amorphous alloy composite material with ductile crystal phase and homogenization method of its crystal phase

A composite material and amorphous alloy technology, which is applied in the field of uniform crystal phase in CuaZrbAlcMd amorphous alloy matrix composite material, can solve the problems of crystal phase size and uneven distribution, and achieve excellent tensile plasticity and work hardening performance , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

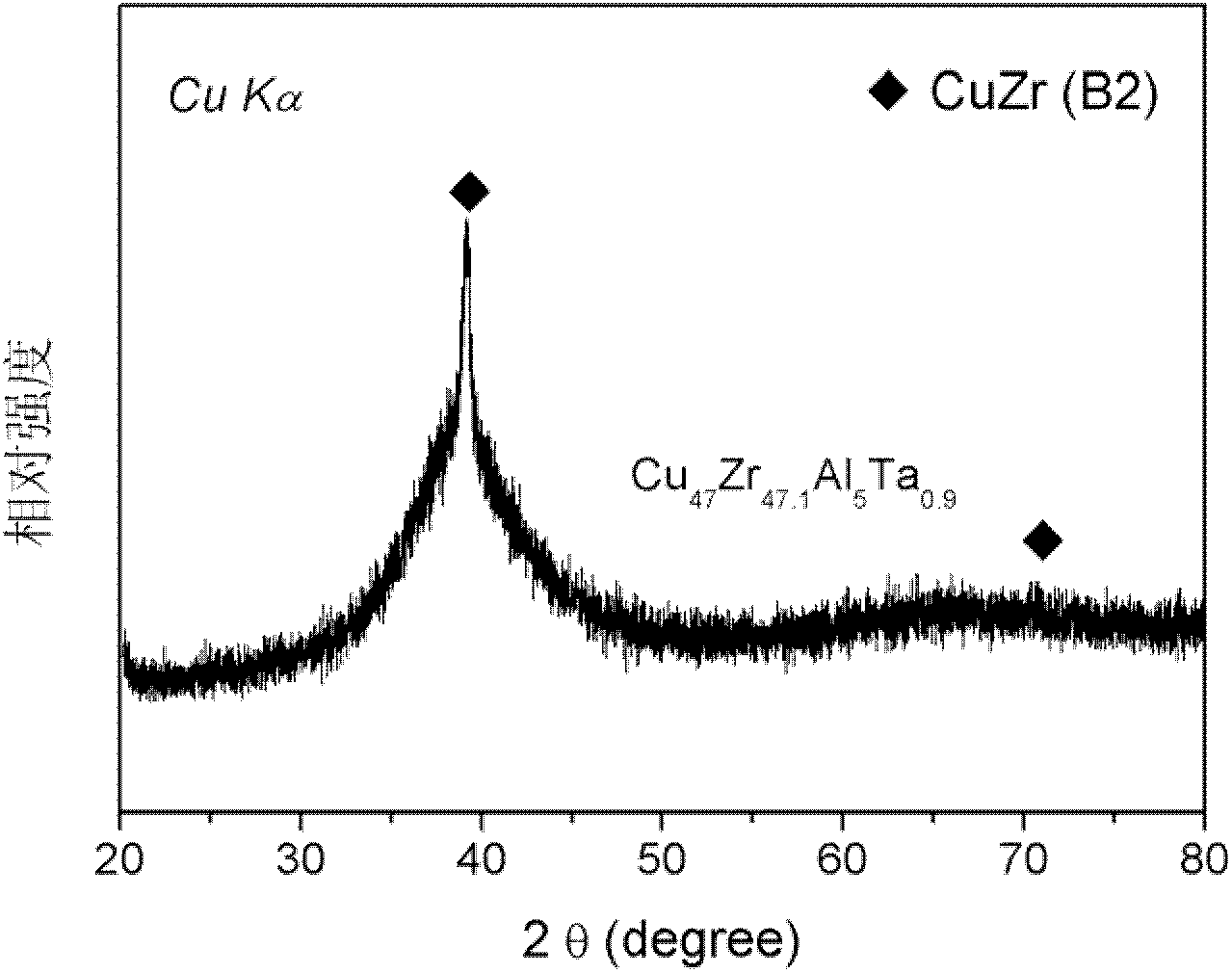

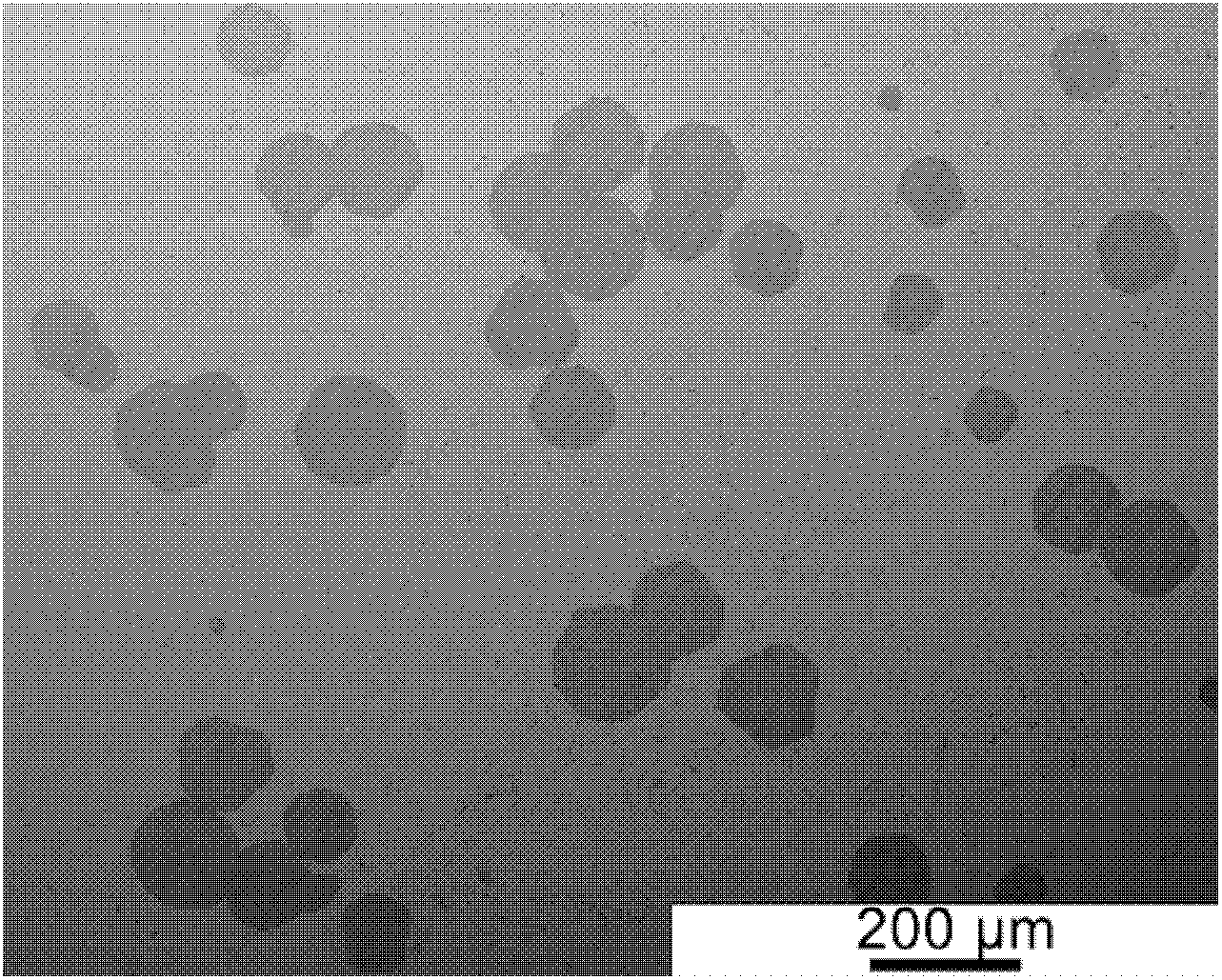

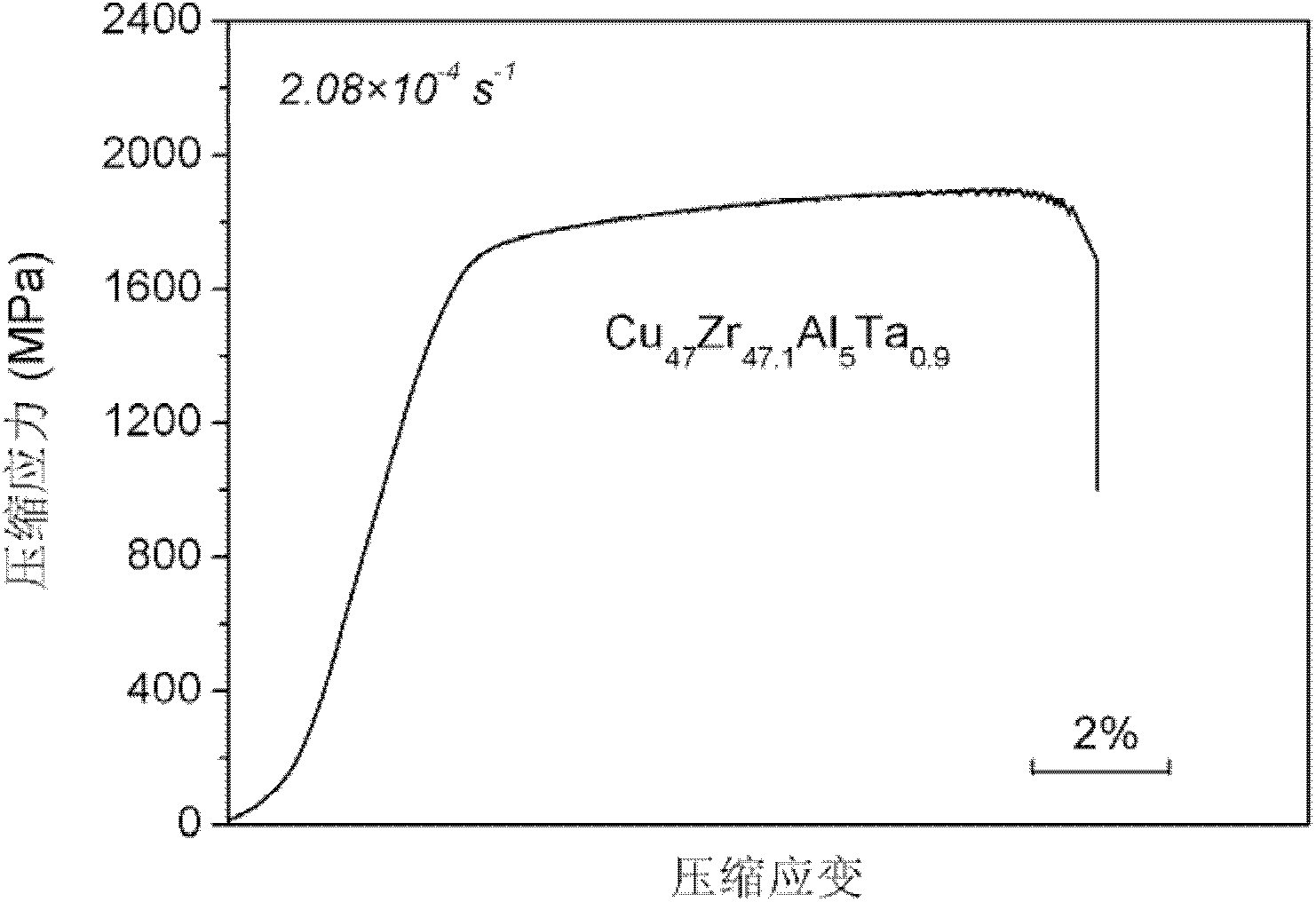

[0035] Example 1 Cu 47 Zr 47.1 al 5 Ta 0.9 bulk amorphous alloy composites

[0036] Step 1: Ingredients

[0037] According to Cu 47 Zr 47.1 al 5 Ta 0.9 The target composition is prepared by weighing Cu, Zr, Al, and Ta elements to obtain smelting raw materials, and the mass percentage purity of each element is not less than 99.0%;

[0039] Put the smelting raw materials into a vacuum electric arc furnace for smelting, and smelt them evenly under the protective atmosphere of high-purity argon with a mass percentage purity of 99.999% to obtain Cu 47 Zr 47.1 al 5 Ta 0.9 alloy ingot;

[0040] Melting parameters: the vacuum degree of the vacuum electric arc furnace during smelting is 1×10 -2 Pa;

[0041] The melting temperature is 1500°C;

[0042] Melting time is 5min;

[0043] Step 3: Casting of bulk amorphous alloy

[0044] The Cu prepared in step 2 47 Zr 47.1 al 5 Ta 0.9 The alloy ingot is put into the induction furnace of t...

Embodiment 2

[0054] Example 2 Cu 47 Zr 47.1 al 5 W 0.1 bulk amorphous alloy composites

[0055] Step 1: Ingredients

[0056] According to Cu 47 Zr 47.1 al 5 W 0.1 The target composition is prepared by weighing Cu, Zr, Al, and W elements to obtain smelting raw materials, and the mass percentage purity of each element is not less than 99.0%;

[0058] Put the smelting raw materials into a vacuum electric arc furnace for smelting, and smelt them evenly under an argon protective atmosphere with a purity of 99.999% by mass, and then take them out to obtain Cu 47 Zr 47.1 al 5 W 0.1 alloy ingot;

[0059] Melting parameters: the vacuum degree of the vacuum electric arc furnace during smelting is 5×10 -3 Pa;

[0060] The melting temperature is 1800°C;

[0061] Melting time is 4min;

[0062] Step 3: Casting of bulk amorphous alloy

[0063] The Cu prepared in step 2 47 Zr 47.1 al 5 W 0.1 The alloy ingot is put into the induction furnace of the ra...

Embodiment 3

[0071] Example 3 Cu 49 Zr 45 al 5 W 0.6 Nb 0.4 bulk amorphous alloy composites

[0072] Step 1: Ingredients

[0073] According to Cu 49 Zr 45 al 5 W 0.6 Nb 0.4 The target composition is prepared by weighing Cu, Zr, Al, W, and Nb elements to obtain smelting raw materials, and the mass percentage purity of each element is not less than 99.0%;

[0075] Put the smelting raw materials into a vacuum electric arc furnace for smelting, and smelt them evenly under an argon protective atmosphere with a purity of 99.999% by mass, and then take them out to obtain Cu 49 Zr 45 al 5 W 0.6 Nb 0.4 alloy ingot;

[0076] Melting parameters: the vacuum degree of the vacuum electric arc furnace during smelting is 3×10 -3 Pa;

[0077] The melting temperature is 1700°C;

[0078] Melting time is 5min;

[0079] Step 3: Casting of bulk amorphous alloy

[0080] The Cu prepared in step 2 49 Zr 45 Al 5 W 0.6 Nb 0.4 The alloy ingot is put into the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com