Method for preparing solar selective heat absorbing paint by using spinel type pigment as light absorbent

A spinel-type, endothermic coating technology, applied in radiation-absorbing coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of not examining the influence of powder structure and performance, affecting product structure and optical properties, etc. Achieve the effect of improving photothermal conversion efficiency, good mechanical properties, simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

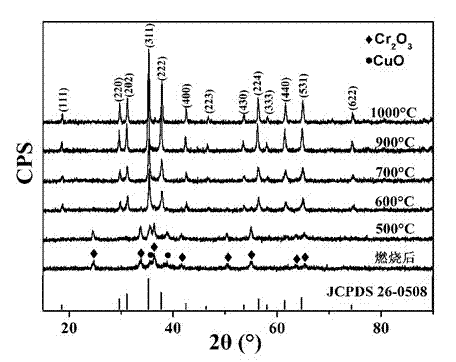

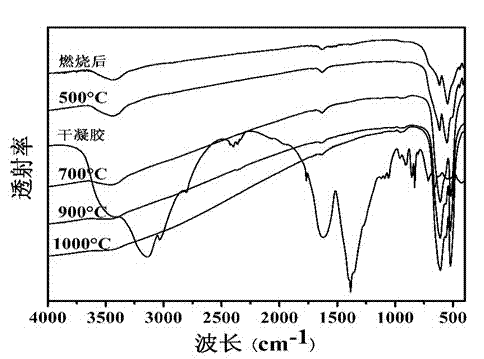

[0043] (1) Preparation of nano-scale spinel pigments: Dissolve 0.01mol cobalt nitrate, 0.03mol manganese nitrate, 0.03mol copper nitrate and 0.05mol citric acid in 60ml deionized water, stir well and add 0.008mol polyethylene glycol Alcohol 200, and use ammonia water to adjust the pH value of the solution to neutral; heat the above solution at 80°C, and after forming a sol, heat it in an oven at 130°C until a xerogel is formed; Ignite it in a medium and burn it violently to get a light black powder; place the powder in a muffle furnace at 500°C for 2 hours to get black nanoscale spinel CoCuMnO x Powder, the powder particle size is 23nm.

[0044] (2) Preparation of paint:

[0045] Recipe: 10 parts of CoCuMnO x Powder, 45 parts of epoxy-modified polyurethane resin, 5 parts of additives (mixed by 1 part of leveling agent, 1 part of wetting agent, and 3 parts of defoamer) and 30 parts of anhydrous xylene are mixed, and the The method is to disperse evenly, and then add 10 parts...

Embodiment 2

[0049] (1) Preparation of nano-scale spinel pigments: Dissolve 0.05mol of chromium nitrate, 0.15mol of manganese nitrate, 0.1mol of copper nitrate and 0.25mol of citric acid in 150ml of deionized water, fully stir and dissolve, then add 0.05mol of dispersant Polyethylene glycol 200, and adjust the pH value of the solution to neutral with ammonia water; heat the above solution at 70°C, and heat it in an oven at 150°C after forming a sol; make the dry gel with a few drops of ethanol The igniter is ignited in the air to make it fully combustible to obtain light black powder; the powder is calcined in a muffle furnace at 700 °C for 1 hour to obtain black nano-scale spinel CuCr 0.5 mn 1.5 o 4 Powder, the particle size of powder is 35nm.

[0050] (2) Preparation of paint: 9 parts of CuCr 0.5 mn 1.5 o 4 Powder, 40 parts of acrylic modified polyurethane resin, 6 parts of additives (mixed from 2 parts of leveling agent, 1 part of wetting agent, and 3 parts of defoamer) and 35 par...

Embodiment 3

[0054] (1) Preparation of nanoscale spinel pigments: Dissolve 0.1mol copper nitrate, 0.2mol chromium nitrate and 0.3mol citric acid in 120ml deionized water, stir and dissolve in the medium, then add 0.04mol dispersant polyethylene glycol 200 , and adjust the pH value of the solution to neutral with ammonia water; heat the above solution at 85°C, and heat it in an oven at 120°C to form a xerogel after forming a sol; use a few drops of ethanol as an ignition agent for the xerogel in the air Light black powder was obtained by medium ignition to make it fully burnt; the powder was calcined in a muffle furnace at 700°C for 2 hours to obtain black nano-scale spinel CuCr 2 o 4 Powder, the powder particle size is 29nm.

[0055] (2) Preparation of paint: 7 parts of CuCr 2 o 4 Powder, 45 parts of acrylic modified polyurethane resin, 8 parts of additives (a mixture of 2 parts of leveling agent, 3 parts of wetting agent, and 3 parts of defoamer) and a mixture of 29 parts of anhydrous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com