Treatment process and system of sludge from wastewater treatment plant

A sewage treatment plant and sludge treatment technology, applied in the fields of sludge treatment, biological sludge treatment, biological water/sewage treatment, etc., which can solve the problems of high requirements on original mud quality, rejection of sludge, and impact on landfills. , to achieve the effect of simplifying the sludge treatment process, reducing investment and operating costs, and reducing the amount of sludge generated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as figure 2 The sludge treatment system shown includes a control system 3 and a reaction tank body, and the tank body is made of glass fiber reinforced plastic. The reaction tank body includes sedimentation tank 2, aerobic digestion tank 6, digested sludge sedimentation tank 8 and aquatic plant purification tank 9 connected in sequence; connection; the bottom of the aerobic digestion tank is evenly covered with aeration pipes 7, and the aeration pipes 7 are connected to the blower 5; the bottom of the digested sludge sedimentation tank 8 is provided with a mud discharge pipe 12; The liquid pipe 13 is connected; the control system 3 controls the sludge inlet volume of the sludge pump 4 and the blast volume of the blower 5 .

[0027] A floating frame 11 of plastic material is arranged at the liquid level of the aquatic plant purification tank 9 to maintain the relative plant spacing of the aquatic plants.

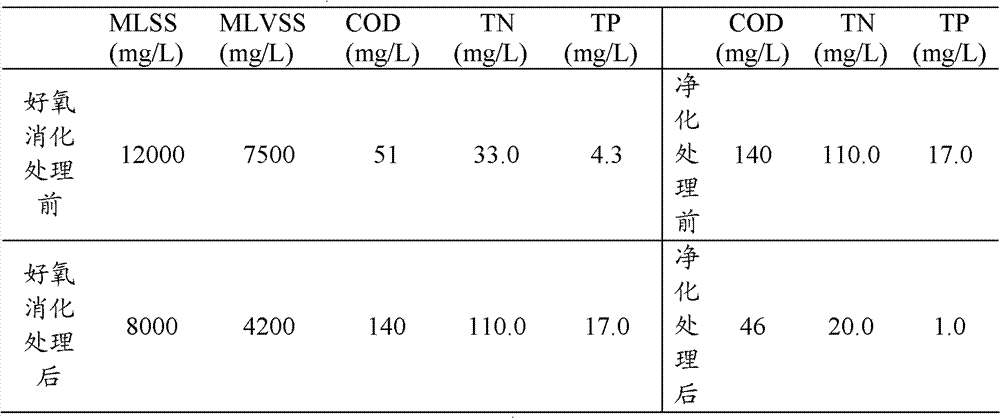

[0028] The sludge of the sewage treatment plant first ent...

Embodiment 2

[0033] Using the same system as in Example 1, the difference from Example 1 is that in the aquatic plant purification stage, the residence time of the digested tail water in the purification tank is increased to 20 days, and it is carried out at room temperature (23 ± 2 ° C), aerobic digestion The sludge concentration in the pool is maintained at 12000-15000mg / L, and the dissolved oxygen solubility is controlled at 5.0-6.0mg / L. After aerobic digestion, the sludge organic matter degradation rate (MLVSS degradation rate) is basically the same as that of Example 1, reaching urban Pollutant discharge standard for sewage treatment plants (GB 18918-2002); digested tail water enters the purification tank, and the planting density of aquatic plants (Pteris chinensis) in the tank is maintained at 25 plants / m 2 After 20 days of adsorption and absorption by aquatic plants, the concentration of COD, TN and TP in the effluent can be reduced to 43mg / L, 14mg / L and 0.5mg / L respectively, reachi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com